-

Content Count

2,241 -

Joined

-

Last visited

-

Days Won

40

Posts posted by Primal Decals

-

-

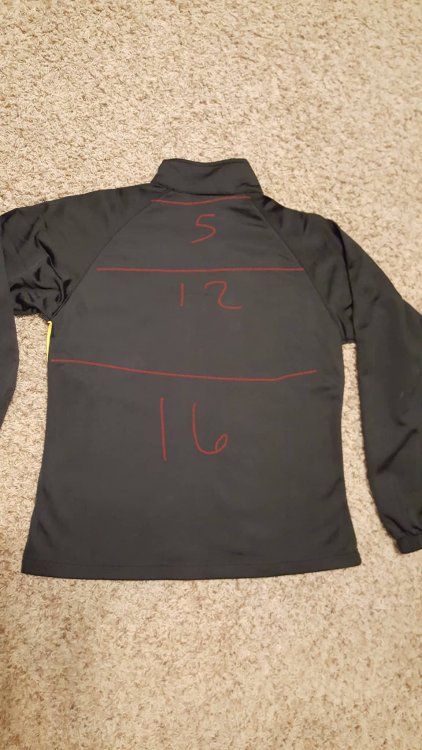

So i have a design that is going on a 100% poly jacket and im using siser glitter for the center design and siser stretch for the lettering around it, MY question is how would i go about pressing these on without ruining the other with different pressure and heat settings? Glitter i believe needed to be pressed at 320 for 20 secs ( im just guessing right now for example) and siser stretch needs to be at 305 for 12-15 seconds. see image for example.Not scaled to true size.. Thank you everyone for your info.

-

Is printing a for sure thing you are wanting to do or ? I thought i was needing to get a printer when i first started and 98% of everything i do ends up not being printed unless its a special thing from a customer that requires color blending or similar needs.

-

Thank you everyone for your thoughts etc..

Just an update. I came back to my hometown after being shortly away and made some personal life changes as well, and im glad i did, It also allowed me to start my photography business back up and still do my vinyl work etc.,So i upgraded and added to my arsenal of new camera gear. Things are rolling good now . Guess some things happen for a reason when they do. Thanks again for your comments.

-

2

2

-

-

nice job bud.

-

1

1

-

-

@carwash...the only one i have is it tells you what it costs YOU in just material only to make something ( width x length ) .( that includes vinyl and transtape) and now i have HTV on my list.......

From there i just make my cost for selling for what i feel is fair and still make good money.Helps me a lot.. Send pm If interested.

-

23 hours ago, MZ SKEETER said:This is the forum not a chat area. UScutter rarely comes here. . Just call them, they are open Pacific time.

Wouldnt it be better if he joined the group instead of being just a guest? I think it would ..Might get better responses etc . just saying..lol

-

1

1

-

-

3 hours ago, bikemike said:My opinion would be move the top text up to give the same space as the bottom text from the logo. probably help with the overall look.

Thanks @bikemike-I understand that and that is what i was going to do, i was curious if the letter size is correct for being on this size of jacket as being 1 1/2 inches tall ? I assumed it should be larger but i could be wrong .Just hoping for clarification on it.

-

Anyone else like the new version ? Just got signed up with the new 2018 version on the cloud. I like the new features it has and upgrades, really like the new font preview feature they added.

-

FIRST OFF - the design is rough draft, i know i need to space everything properly drop down etc. I just thru this together real quick..Busy day

, im just going after the letter size issue i dont like.............This is my first go round with this area on cheer jackets... So i have a cheer jacket im working on and i made a mockup design how they want it but not placed and spaced yet. ,they like the overall design etc .,But what i am having an issue with is the size of the letters are coming out to about 1 1/2 inches tall roughly . Is there a standard letter size for doing these and how do i get larger and making it look right?. Whats killing my size is the overall length of CHAMPIONS that i can see. This is the font they want and the design in the middle .

Any help will be awesome.. and pointers etc .100% poly using glitter for the center design and siser stretch for the lettering. Thank you again Pippin.

-

i couldnt get your link to open. Does it just flat or coned shaped if you understand what i mean. I dont know the terminology of it lol and what sizes will it do.

-

If they have the 28" model you will get best results with all 3 pinch rollers to the right. Plus i never run my material that far over to the right either, I leave about 1-2 inches max past the far right roller. Any more will cause the material bunch up and cause that issue in the photo..

-

On 10/12/2017 at 3:13 PM, MZ SKEETER said:@Primal Decals Will the Titan2 work with the far right pinch roller on the 2nd grit roller? Does it operate that way, or is it required to have the far right pinch roller on the far right grit roller only?

It will work on either ..

-

cricut is a web based software only.the only way you are going to get access to them is if you save them export ( if it will anymore ) to your computer. I was a user of the cricut for awhile and it sucks for doing what your attempting ..they might have stopped it from being able to save things from your online cricut storage to your pc..

-

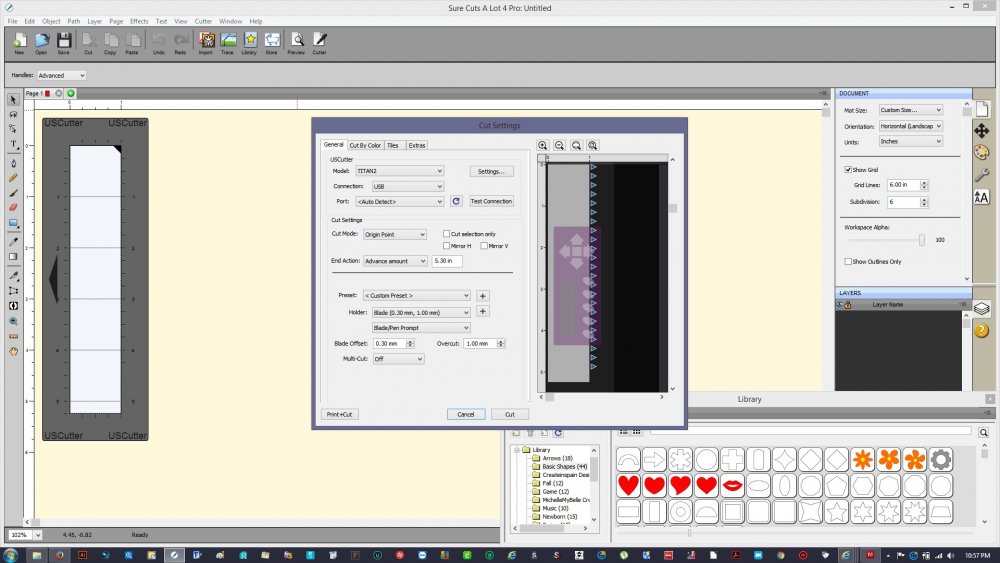

Here is what my settings are. In scalps, when you use the text feature you have to go to TEXT and then convert text to outlines, From there you can scale it to the proper size you need it to be,Its just like in ai Its not a vector till you convert it..Im also sending a ticket to craftedge on this ..

-

1

1

-

-

ditto- paper tape

-

I wash all clothing no mater where it comes from first off........This is a tough one for me to decide on what i would really do, I know that a customer supplied shirt is to be a gamble due to the technicality of how it was washed etc , But for me whether or not they supplied the shirt or not ,the main issue was with the transfer which in turn ruined the product not the clothing having an issue. I personally would have to replace the customers clothing .It was not the clothing that caused the issue in this matter.

What if you did a decal on a vehicle and for some godly reason the adhesive ruined the clear coat due to a mix up in the chemical adhesive ( Not that this would really ever happen but just an example) .The material you supplied to put on the vehicle ruined the paint, Does that mean your not liable for fixing their paint job ? Or tell the customer since you supplied the vehicle i wont take care of you but i will give you a deal..lol Sorry but whatever product im supplying that ends up having a defect to cause an issue falls on myself or the manufacturer who supplied the item... I would have to eat the cost of the shirts and put it on the supplier if possible, otherwise eat it and move to another supplier,, But what do i know... lol..

-

1

1

-

-

2 hours ago, Go-C Graphics said:I replied to this. I don't know where it went.

Shoot me a message with the details and the graphic and lets take a look at this.

I'll be happy to help.

sounds good ,will do.

-

-

On 10/11/2017 at 5:29 PM, 88x said:Not sure @Ed McCarronif you upgraded but @Primal Decals I found a way on SCAP 4 to make the letters follow the circle perfectly.

Here's what I did:

Make your circle to what ever size, then do your text in a straight line.

Select the text and the circle at the same time

Go to the "effects" tab on the top, then click "object on path"

Bam it turned out awesome

@88x nice job bud...thanks alot.. Ive been away working on other projects like my photography as well... Just upgraded my whole photo kit., Now i will be doing both lol

-

2

2

-

-

On 10/9/2017 at 6:00 PM, Wildgoose said:One trick of the trade is to place the roll on the back rollers feed some through and hold the roll down so it sits well nestled in between them with any excess rolled up tight. Pull lightly on the end you have coming out the front while you keep the pressure on the roll in back and this will create a square position with the cutter. You may have to slide both eh roll and the end you hold around a bit until you get it where you want it but this will help you get square and should help with the feed. Once you clamp it then do the pre-feed as Skeeter says for the length of the proposed job and you will know before you cut that it will stay straight. If your material rollers on the back have any kind of plates that will hold your roll from walking sideways that is a plus. This all assumes you have a stand and rollers on the back. If not then you just have to play with it until you fine the sweet spot and maybe mark a line with a piece of tape just outside the edge or a sharpie (this is if your rulers are not aligned).

@mckenna.mengelkoch...Very true what Wildgoose says, I actually ended up taking one side of the rulers that are adhered and flipping it around, ( Because the numbers are switched on one side from the other and made a big difference when i started, Now i just align by site and forget about using the back side of the ruler. Also add some light to your cutter front like i did ,cheap to do and simple as well without messing with warranty.

-

I started doing some chemical etching on glass with a design i did for my dads school. i have the rights to the design and i have re-designed it to a better look. But im deciding whether to try and find someone who does laser etching etc to make better use of the time lol.. I will supply the glasses as needed unless someone can get a better deal instead,,Please contact me and i will supply the images of choice we will be possibly using .Im just looking for a quote for the laser time and shipping, glasses etc. Right now we are using stemless wine glasses. I can supply my cell number if needed to make it better to communicate.

Unless someone can tell me a laser machine i can buy instead under or around $1500 or so. Thank you for your time buddies. By the way i havent been on here much due to the internet is crappy and its limited use per data package lol..

-

23 hours ago, cardudenc said:a lady at the flea market here runs canvas thru an Epson 7610 printer. not sure if that's what your looking to do. can get some pics of what she sells

I need more info bud on this lol

-

On 8/3/2017 at 5:01 PM, cardudenc said:unfortunately for @Primal Decals he is my go to... i.t. tech, graphic designer, just about anything guy now. lol

lol..

-

why are you getting rid of it? And what kind of quality is this.. Will it do coned shape( or what ever its called glasses ) wide to narrow bottom style? if you know what i mean.. new to this terminology for mug style presses lol.

Material help on HTV

in T-Shirts and/ or Garments

Posted

Thank you @mfatty500. i was really lost on this lol.. So next time i know .