-

Content Count

17,526 -

Joined

-

Last visited

-

Days Won

498

Posts posted by MZ SKEETER

-

-

Great, glad they could get it fixed.

-

Hopefully you have plenty of vinyl free to do the entire order and you are not pulling from the roll. Never pull from the roll while cutting. Did you mess with the pinch roller tension? You shouldn't. Do you have the pinch rollers over the grit rollers on the bottom? They should always be. Make sure the set screws in the grit rollers are tight. Does it do the same thing with a pen drawing?

-

CE7000 Expanded Cutting Area

It expands the cutting area to include objects outside of the area enclosed by registration marks. Production efficiency is enhanced by reducing media waste.Your user manual is your best friend. Search under PUSH ROLLERS, In the INDEX. You can turn the media sensor and pinch rollers off. (Push rollers. 1-4, 1-6, 1-8) (Push roller sensors.10-5 ) This info is in your Graphtec user manual which can be found on the Graphtec website. Many people use a cutting mat, so they can hold smaller vinyl. can be purchased at Walmart and hobby shops. Ebay.

Also, is there a carrier sheet I can attach my "magnet sheets" to to make sure they're square?

Personally I would never cut magnet sheets on my Graphtec, and my cutter has a lot more force than the CE7000. That is a lot of wear and tear on an expensive cutter. A Cricut can do it with a DEEP CUT BLADE, But that is your choice to make. Maybe possible with 2-3 passes so it isn't trying all at 1 time.

-

You could go to Vinylmaster.com and get a current updated version of VinylMaster Cut for around $60 and be cutting today. You could also try their trial version. https://vinylmaster.software/products/cut Signcut I think, also has a trial version. The Copam has not been sold on UScutter for several years, which is why threads are old.

Info for the Copam

https://support.uscutter.com/hc/en-us/sections/360007369351-Copam-Vinyl-Cutter-Series

-

-

It could be a VERY long wait to get your question answered then. Good Luck.

-

As soon as you wrote Mac, you lost here. Most anyone here is a Windows user that answers questions . And don't know of anyone using Cutting Master 5. There is only a couple handful of members here that answers questions. Graphtec provided you with a GREAT over $1000 design and cutting software FREE with your purchase. WINDOWS ONLY., if purchased new. Which is designed by the creators of FlexisignPro, (SAI), without the RIP. GRAPHTEC PRO STUDIO. Grab a windows computer and you will be much further ahead. There is support for that. You could also use Bootcamp or whatever else you can use on a Mac computer to use a Windows program. We are a bunch of old timers here, who don't need to upgrade to newer software. I am still back on an XP laptop on a purchased new 2008 Graphtec FC7000., using Flexistarter 8.6, Plus I have an FC8000, We have no need for the newest soft wares. Or upgraded Windows. Most users who come here, get their questions answered, if we can, and they move on.

-

We have no clue what you have tried.

Other option, Try a different blade holder, different blade. Are you sure that you didn't break the blade tip off? It is very easy to do. It is very hard to see a broken blade tip with the naked eye. The square and triangle should be perfect without software. Personally I use controls on my Graphtec, only from the Graphtec Cutting Controller. I never use controls on my vinyl cutter it's self. Only to set the Roll>enter. I have my pinch rollers sensor and media sensor turned off in Background settings, so that the cutter doesn't measure the vinyl and have to mess with the pinch rollers being a little off. Make sure the blade is spinning good, Put a little light oil in the blade holder.

-

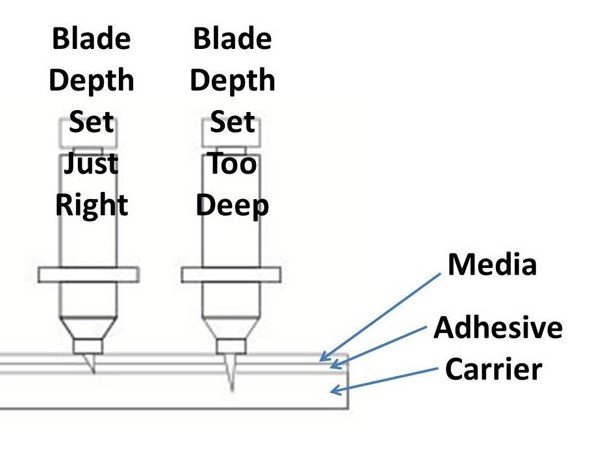

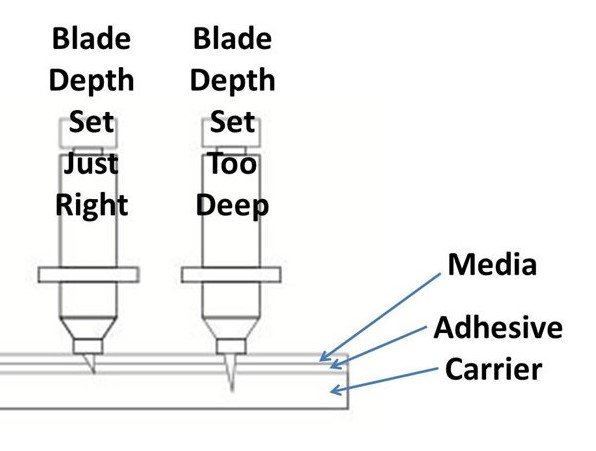

Let's start with the basics here. Blade depth. That is where you start your set up. Too many incorrect instructions out there. This works for correct blade depth. This has helped hundreds on this forum. You don't need that little piece that Graphtec sends to set blade depth. You set this to the vinyl you are using/cutting at the time. Make sure you have the blade holder in the correct hole over the cutting strip. And that the blade holder is down and secured by the flange holding it down.

To start with, you should set your blade depth correctly, by taking the blade holder out of the machine, and firmly cut across a piece of scrap vinyl, you will be cutting. You should only be cutting the vinyl and barely a mark on wax paper backing, Adjust blade to get there, Then put the blade holder back in machine, and use the force of the machine to get there, same results, only cutting the vinyl and barely a mark in wax paper backing. You should barely see and feel the blade tip out of the blade holder. Regular sign vinyl is only 2-3 mil thick. You only cut with the very tip of the blade. When you think the blade is so far in the blade holder, that you think it would not even cut, that is probably correct. -

Maybe this will help you? There are others also searching online or other instructions

https://onlinepngtools.com/remove-png-border

Can't you convert the PGN to a Jpg https://png2jpg.com/ Or Export in your cutting software.

-

Did you see this cutter preform before buying? Ask the previous owner about the error. Not many people here who even own a Roland that answers questions. Probably more help at the Roland Forum . Roland has their own forum.

-

1

1

-

-

To remove the small j >Go into back ground settings. Step thru settings, > Initial blade to> outside..

-

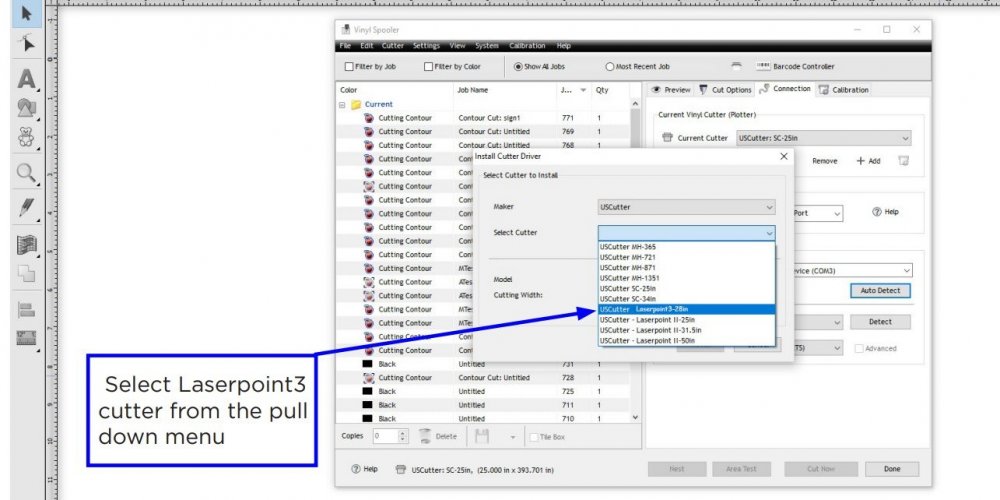

Which laser point do you have? There have been 3 different models. #1 was a Creation Pcut with a laser. #2 was a Liyu, with a laser.. #3 maybe a Liyu with ARMS. . Show us a picture of what you have. Use a direct connect instead of auto. Why are you choosing UScutter SC2 as your cutter? It looks like you should be choosing USCUTTER LASER POINT, depending on which version you have. Look further down on the drop down box. Also sign up and it won't take you so long to get your post added to the conversation.

-

What are you calling the "plunger"? Are you talking about the blade holder, that holds the blade?

This? If so, you should keep spares as well as many blades. Much cheaper to buy on Ebay and they are mostly metal. Last I picked up were metal and work fine. I got mine for $9.99. a few years back. Now I see plus $10 and up.

https://uscutter.com/graphtec-0-9mm-blue-tip-blade-holder-for-cb09-blades/

-

Vinyl Master has many, many topics and tutorials. Did you go to HELP at the top of your layout screen and search the HELP topics? The instructions to your software are under HELP. You could also search youtube, Did you check the comparisons between different upgrades of Vinyl Master to make sure such a feature is available in your version?

-

Depending on how large your design/nodes/order is, you will want to hit reset anyway. The SC631 is limited in memory. You may find it stopping in the middle of jobs, if you don't dump the previous orders data.

-

Found this thread from previous ops with the same problem.

-

Many people on here use Clean Cut blades and swear by them, I personally use Seiki blades for my Graphtec and get 8-10 months cutting sign vinyl. Plus they are much cheaper at 5 blades for around $25 free ship out of, Sparks, Nevada. I don't cut paper.

-

paper will dull blades very fast.

-

1

1

-

-

Have you watched this video? Do you have your job/vinyl set up correctly in the cutter throat? I only know of 1 person on here that answers questions who has a Graphtec FC9000. Have you contacted your Graphtec tech support?

-

I hope you are prefeeding your vinyl before cutting, so you are not pulling from the roll while cutting. Always have enough vinyl slack to do the order. I would guess the vinyl is slipping, You shouldn't adjust the pinch rollers, as a rule. Also, how did you set your blade depth? Too much blade extended out of the blade holder will cause drag on the vinyl. This is the correct way to set your blade depth for every type of vinyl. Never use a credit card or post it notes for setting blade depth, it is about 10 times too much blade extended out of the blade holder, It's a myth that just won't go away. Make sure your pinch rollers and grit rollers are tight and clean. Your test cuts from the TEST feature on the cutter are coming out correct?

To start with, you should set your blade depth correctly, by taking the blade holder out of the machine, and firmly cut across a piece of scrap vinyl, you will be cutting. You should only be cutting the vinyl and barely a mark on wax paper backing, Adjust blade to get there, Then put the blade holder back in machine, and use the force of the machine to get there, same results, only cutting the vinyl and barely a mark in wax paper backing. You should barely see and feel the blade tip out of the blade holder. Regular sign vinyl is only 2-3 mil thick. You only cut with the very tip of the blade. When you think the blade is so far in the blade holder, that you think it would not even cut, that is probably correct.

-

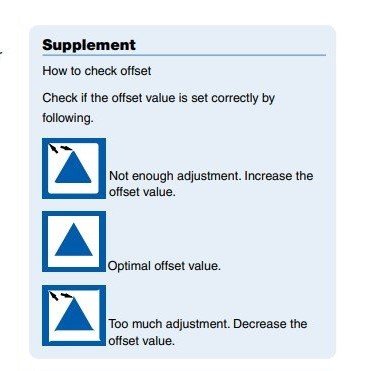

. Has this cutter ever cut correctly? Is it new or used? Your cutter is a value cutter with a cheap Chinese chipset on it,, will take a bit of fine tuning to cut correctly. Best to use with a Tripplite Keyspan Adapter and your null modem cable. Setting your blade depth correctly is the first thing you have to get correct, You do not use the depth of a credit card or post it notes. That is way too much blade exposed out of the blade holder. You set the blade depth to the vinyl you will be cutting.( Instructions below). For blade offset, start at 0.25mm and adjust at 0.05 to be correct. Show your test cuts from the TEST cut feature on the machine. That has to be correct first, before you cut anything. Square should be square. You could also ad a little overcut in your cutting software, but that is not going to fix what you have going on. You have to start with the correct blade depth first. this info has been posted on here hundreds and hundreds of times, it applies to any brand of vinyl cutter, except a Graphtec has a ZERO blade offset. Something that you will have to do if you haven't, if that cutter is on a stand, it needs grounded to the stand, or static from the vinyl, will stop the cutter. The tracking is not good on those cutters for larger designs. The memory is also not good for larger designs.

To start with, you should set your blade depth correctly, by taking the blade holder out of the machine, and firmly cut across a piece of scrap vinyl, you will be cutting. You should only be cutting the vinyl and barely a mark on wax paper backing, Adjust blade to get there, Then put the blade holder back in machine, and use the force of the machine to get there, same results, only cutting the vinyl and barely a mark in wax paper backing. You should barely see and feel the blade tip out of the blade holder. Regular sign vinyl is only 2-3 mil thick. You only cut with the very tip of the blade. When you think the blade is so far in the blade holder, that you think it would not even cut, that is probably correct.

-

2

2

-

-

This thread is on a CE6000, but is it anything similar to what you are getting? Part of his problem was the resolution, ( Steps). as well as his carriage was loose a little bit. And blade depth.

-

Rest in peace Bill.

LaserPoint 1 driver for windows 11?

in LaserPoint Cutting Plotter Support Requests

Posted

You could always use the cutter with a Tripp-lite Keyspan Adapter and a null modem cable, It has a better connection anyway. Tripp-lite is the brand name. The Tripp-lite has it's own driver that you download.. You locate the com port number in device manager, and use the same com port number in your cutting software.