-

Content Count

21,365 -

Joined

-

Last visited

-

Days Won

641

Posts posted by Dakotagrafx

-

-

is your software activated?

-

there is no way with a cricuit easy press ( essentially a big iron) to get a even heat nor even pressure over time on a transfer if you are thinking of selling you product - time, temp and pressure are all important when applying HTV for customers

-

2

2

-

-

50 minutes ago, pawdell said:Yes, please do.

If improved, I might think about selling my 6000 60 plus to get the 7000 for the few features the 7000 has over the 6000.

actually biggest mistake I ever made - hold onto and love that ce6000 IMHO

-

1

1

-

-

if you really want to mess with it some more before you buy any parts to troubleshoot which part it is - you can take it apart and try reseating all the connections and ribbon cables, just to rule that out - but realistically if you start buying a new mainboard and display and that doesn't do it (or even if it does) you have put a lot of money into an OLD plotter that has served you well - I have repaired and refurbed many plotters and just my 2 cents - it is time to put that old work horse out to pasture

-

5 hours ago, slice&dice said:Fried. It happens, especially with the ungrounded MH. They are notorious for that.

Grab the 34" SC2, it's around $600, shipped (provided with stand & media basket and good design/cutting software bundled).

You can pay off that expense in one or two larger jobs, and these days you'll find plenty of sign work available everywhere.

I just did these 4'x8' panels for a junk guy's trucks, over $800 job (2 trucks). My advice, put the old MH to the side, start fresh with the SC2, and don't worry about it. Life is too short, man.

nice work slice

-

have your checked the temp on your press with a ir thermometer to make sure it is accurate - maybe the black is more sensitive to temp than the other colors or could you have a bad batch of black HTV?

-

2

2

-

-

1 hour ago, dirtymonkee said:I’ve inched it less and less upped force but it either distorts or don’t cut.

It weren’t this hard to set up when I didn't know what I was doing.

with the pen doing a good job it comes down to either the vinyl moving within the pinch rollers because they are not applying enough pressure to hold the vinyl where it should be OR something not right with the blade or holder -

-

not exactly sure what you are saying in your post - the printer doesn't deposit ink on the paper? if so a printer problem - or the printed image won't transfer to the shirt?

if the second I am not familiar enough with a cricuit press but doubt it would hit the 400 degrees necessary for sublimation ink to turn to gas. second is the shirt needs to be 100 percent polyester, 50/50 shirts will transfer ink to the poly portion of the shirt and give a distressed look. sublimation paper also has a right and wrong side - usually the right side is a slightly brighter white -

static can cause issues with the mainboard as the static from the roll is discharged thru the carriage - the mh has had at least 3 different mainboards over the years so finding the right one might be hard - after 14 years might be a good time to move up to a sc2 or titan!

-

2 thoughts - are you pre pressing to get the moisture out of the garment before applying your graphics? are you buying the shirts from a wholesaler or a retail store - in the past we have had members report that shirts that are displayed in a retail setting are sometimes coated with a substance like starch to make them present better on the shelf. just thoughts and far from the expert on this one

-

2

2

-

-

we look forward to your review on this after you receive the new plotter - fingers crossed that the early problems are fixed - it sure did drive up the price of the remaining ce6000's

-

8 hours ago, dirtymonkee said:Admittedly I did see more marks In the vinyl then I am now so maybe they do need to be tighter but I have also tried this before. Will try again, my fifth day of trying to sort. I do appreciate all your help.

If all else fails can someone point me in the direction of a decent cutter? Don’t need to be as big as the 721

hoist that roll of vinyl up and put a new graphtec under it - if it doesn't need to be as big look for an new old stock ce6000-40 - haven't seen any reports on the 115" version like that but lots of issues with the new ce7000-60 since they moved production. also not familiar with the UK market other than I know they have the graphtec, roland and summa plotters - all of which are a large step up from the refine MH -

very little marks on the vinyl would indicate the pressure is not high enough on the rollers - the marks are normal and go away when the vinyl is installed -

29 minutes ago, dirtymonkee said:So, something fundamental has changed and can’t be fixed. This is how it seems. I give up, it has me beat.

Just for troubleshooting tighten those pressure rollers a little more . . .

-

4 hours ago, dirtymonkee said:I have, to try to alleviate issue but changed back. This is what they are on now. Level with screw. No pressure, less or more made any difference.

too many people over the years have lowered the pressure to eliminate the marks made by the pressure rollers that are totally normal and cause problems similar to yours - as the blade causes more friction than the pressure rollers the vinyl slips - kinda thought from the pictures the pressure had been lowered quite a bit.

On yours compared to the others I have seen the spring has the top coil pulled up quite a bit - on most the spring separates evenly throughout the coils as the pressure is increased -

one more quick question - You haven't changed the pressure on the pinch rollers at any point have you?

-

40 minutes ago, brandenallmon said:Anyone know what is used to achieve this faux etch look?

looks like a paint we used to use on aquariums in the 70's - I would just do it in an etched vinyl like sold here

https://uscutter.com/etched-frosted-dusted-glass/ -

5 hours ago, Ayomide said:I plug my Seiki plotter to find out the power on and off is not working anymore , what can I do ?

the seiki isn't sold by uscutter but we do have a few users on here with them - I would start with trying another power cable (yes I have had one go bad) - then look into a new power supply if you can find one. other possible suspects are the mainboard or control panel so it is a trial and error on a little supported plotter

-

9 hours ago, haumana said:I am envious of the roll holder!

I have 2 of that one along with a home made one, but trying to free up space in the basement work area. the one I am selling I used to put empty tubes on and hang some of my printed ready to sell stuff on

-

2 minutes ago, CBCD said:Using flexi trying to get the vinyl express q130 to cut. Can’t find the issue. Can see it on PM but when send to cut it does nothing. All help is needed please!!!

vinyl express cutters are rebranded graphtecs with a proprietary chipset in them so they only work with sign warehouse drivers - flexi should have sign warehouse drivers with the units listed under that - so if a updated flexi you should be good to go

-

1 minute ago, MZ SKEETER said:Reread Scott. LOL He doesn't currently have a cutter. ( "I don't currently have a cutter") He wants to know if the roller issue has been fixed, so that he can buy a Graphtec CE7000

you are right again. heck I would like to know if they ever fixed the issue too - but not buying another one to find out

-

1

1

-

-

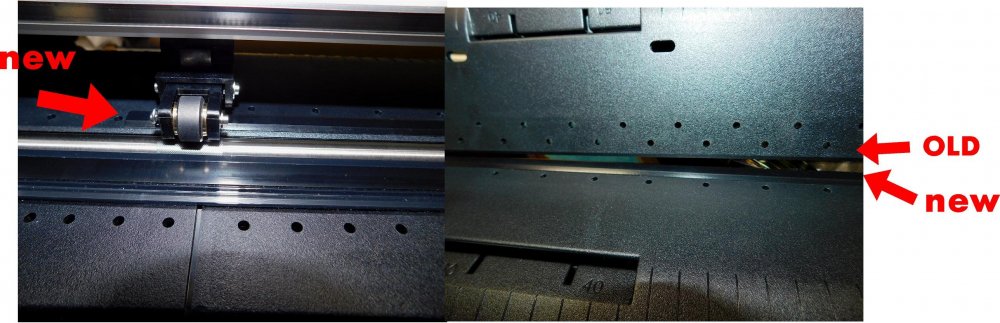

On 8/10/2020 at 4:21 PM, Dakotagrafx said:this is the difference in the new and old guides.

maybe someday I will get the opportunity to play with another ce7000 and see if they fixed the issue -

On 7/25/2020 at 2:12 PM, Dakotagrafx said:I am wondering if this is what the original poster had encountered. I have a lot of seat time on the graphtecs and this is a new one on me - will probably have to wait till first week of august before I can call graphtec support but it is not the amount of rollers causing this, there is something else going on.

I did notice the new graphtecs are produced in thailand :/this is from the one I had -

-

1 hour ago, New2022 said:Hi,

I'm new here, I just signed up in the hope someone can tell me if this issue is now fixed? I ask because I was literally about to order a Graphtec CE7000-60 after looking for a vinyl cutter for the last couple of months and then I came across a YouTube video showing the problem. There were a few comments by others with the same issue, one of the users said:

and when the user was asked if the guide fixed the problem, they said:

If the worst case is waiting for a guide that will 100% fix the problem, I'm OK with that.

when I got mine they sent me the new material guides and I worked with graphtec a while trying to cure the issue - I finally fixed it when I sent the ce7000 back and got the fc9000 - hurt the pocketbook but sure cuts fine

-

Welcome from Michigan -

how is the ce7000 working for you?

-

1

1

-

Sublimation not coming off printer paper

in Sublimation

Posted

the ink has to reach around 400 degrees to turn to a gas and attach to a polyester surface - if the press is not capable of reaching 4000 degrees the ink will not turn to a gas so no transfer will happen