-

Content Count

21,363 -

Joined

-

Last visited

-

Days Won

640

Posts posted by Dakotagrafx

-

-

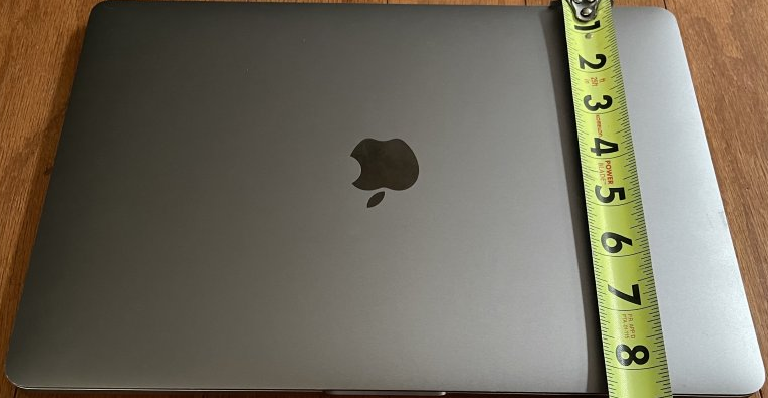

this is what goose is saying - I put a square mask around your computer and cut it so you can visualize the distortion created by the angle and the picture not being straight down

-

1

1

-

-

1 hour ago, annarface said:Hmm. I feel if it were loading straight it would probably cut perfectly as the accuracy issues are consistent with where it's becoming misaligned. I'll cut some more sheets and triple check it's not me loading it incorrectly, otherwise I'll drop them a line tomorrow.

Thanks for your help everybody. Appreciate the heads up re: blade too as it has improved my cuts! Will let you know how I get on and would love to hear if you think of anything else

If loading crooked was the problem the cuts up and down wouldn’t be constantly the same distance from the edge. That is why I think calibration of some sort . . . If the vinyl isn’t punching up when feeding back and forth like the one I had did.

-

the feeding straight has more to do with how it is loaded - I would contact graphtec GB directly - seems to be more of a calibration issue from what I am seeing.

https://graphtecgb.co.uk/ -

Very glad it all worked out in the end - grants etc can be frustrating to meet the criteria (from personal experience with state bids) but glad in the end they made it work

-

Did the place you bought it offer any kind of support like uscutter call center? Thinking they may know their own machine.

-

what skeeter said, I had 3 roland print/cut and you blade exposure is out 10 times too far.

word of advice - keep on your weekly maintenance and keep it printing - solvent printers do not like to sit and the head alone on the bn-20n is around $2000 - not individual like the sp-300i which is only $750 per head. always keep extra ink on hand so it never runs out and let it do it's daily cleanings. -

1 hour ago, curlyp said:wow...amazing! I was just curious about the vehicle wraps. I would love to play around with it on my truck. I had an idea of doing a military themed wrap. So the design under the printed on this truck is cut vinyl? 10 yards of Dark Red 951 is almost $69! I wonder if I use cheap 500 vinyl first to play around if I decide to do it.

cheap vinyl won't work like cast - cast (more expensive) is actually thinner and stretches around the compound curves better. go to a nbm show in your area when they come around

Indy is closest to you and in June - always a great experience

https://graphics-pro-expo.com/events/ -

1 minute ago, curlyp said:Interesting, thank you for the tip. This skin for only for myself - when I wear my watch, it rubs on the laptop aluminum body as I type. I had no plans of making these to sell!

Side question that has nothing to do with my post. Is it possible to use my SC2 28" cutter to make vinyl wraps for my vehicle?

good time to learn than on one for yourself

usually wraps are printed (but cool effects if you put cut vinyl under the other vinyl that shows thru . . . they are either solid color or the printed and put on the vehicle and then cut with a razor blade - lots of hours into learning especially on those compound curves. wrap vinyl is also very expensive - look at the oracal 951 for solid color and some knifeless tape. youtube videos make it look easy from the experts but trust me it isn't that easy.

when you get really good you put cut vinyl under the printed and make it look like tattooed vinyl wrap - keep in mind the guy that did this is one of the 3 best in canada and travels the world doing wraps but was on our forum when he started.

-

I always made my own templates with precise measurements , then dial in with test cuts. Takes time and effort but was well worth it

-

2

2

-

-

8 hours ago, Lee1985 said:or its staying in too long a skewing off

Actually that is where your blade first rest and is drug into the position to cut, quite common on value plotters and small cuts and the nature of a drag blade plotter. You will find it quite different going from a Roland to and entry level plotter

-

Which model plotter? Which software? What printer?

-

1

1

-

-

try a 60 degree cleancut brand blade . . . . and follow skeeters instructions for least blade exposure and slow

-

1

1

-

-

3 hours ago, Scratchthejeepguy said:USCutter finally stepped up and shipped them out with rush shipping.theyre not here yet, but should be tomorrow. I'll check out Grimco though, it's good to have options.

thinking about it - usually bannerjohn would message me when mumpower had their specials and that was probably the cheaper shipping - but what you was quoted still seems way excessive

-

1

1

-

-

6 minutes ago, Scratchthejeepguy said:I just checked out their website and while they're site was very unimpressive, they're prices weren't. I asked for 50 each of the blank signs and stakes and they had to call me back on shipping...

They called back and said shipping alone would be 85.00-90.00!?!?!?!

USCutter charges 11.99?

You buy regularly from these guys Dakota?

I have used them but shipping wasn’t that high. Uscutter actually loses money on shipping I was told, not sure why my power shipping was so much. Been 2 years though since I ordered from anyone, don’t go thru as many now that I sold the printer and don’t do as many golf / charity event signs.

-

mumpower in virginia - always keep extra on hand!

-

what plotter and did you adjust your pressure rollers ?

-

1

1

-

-

Mine cost a little more but made one years ago using a Newman roller frame from screen printing and clear app tape. Has served me well over the years

-

I haven’t seen it either on the iPad

-

In 7 years of printing I can honestly say I never tried exporting from verse works as it is primarily a Raster Image Processing program and I prepped all my contours in flexi pro

-

4 hours ago, KenGraphics said:Link removed

This is where you can get a new one if you are interested as I have heard a ton of issues with the CE7000 models. Most run back to the CE6000 models. Thats another train wreck. CE6000 was my first choice after doing research. Let us not bring up the years I have, just knowledge working with vinyl and vinyl cutters will do. I will make the comment and leave it at this. For a high priced machine with all the bells and whistles... It is a major let down. For me personally. Now there maybe a few that enjoy this cutter and you are one of those people congrats. You must be using their software and must have received one that is perfect out of the box. I still argue that a 60 degree blade will not fix an issue with short fallen cutouts and nor will it fix jagged lines in a vector. I am going to download and test the software that came with this machine. I am willing to bet that the issue disappears if you use their software. But that would burn me if it does because that locks you in on that software. I have been using VinylMaster for years and know my way around in there like the back of my hand. No reason to leave perfection.

Yup, that supplier scares me and understand where you might have trouble with support there. Their description says it has 5 pinch rollers, never seen one yet with that many on a 24” plotter. Does yours have 5?

-

Curious what speed you are running. I have had 2 or 3 ce6000’s and one ce 6000 plus.

-

24 minutes ago, KenGraphics said:I see this is an old thread. But I am having this same issue with a brand new CE6000-60 PLUS model. I have been cutting vinyl for over 10 years with all types of brands of cutters and I have never seen a cutter so complicated to get it setup correctly. I think people get so ticked because of the way some people come off to them. They are stressed because they have invested money into something that should not be so complicated. I was getting that the repeated comment seems to be to fix an issue with the cutters by Graphtec is to adjust the blade or replace a blade. I promise you and anyone, Blade adjustment is good but is not what is causing these issues. This seems to be an undercut issue. I am on the edge of returning the cutter I purchased because the lack of phone support is not there for this product. They want to email and not help at the moment you need it. No where else do I or have I ever had an issue with this. I have been using another brand of pro cutter for the past 5 years and never had issues like this one has gave me. Believe me, I seen people on here ask for help on jagged edges and seems like the same people wrote, check your blade. Offset 0... Change to HPGL mode. What do you say to someone who has the years I do and already have this set and see issues with jagged edges? Could it be the brand new blade? I think not. 45 Degree blades are meant as the main stay of a vinyl cutter. A 60 Degree is used for thick and rough vinyl materials. I was told to use that in one post.

Bad advice. Also I see that jagged edges at are on a vector Graphtec will cut that jagged area as it is. It will not smooth it out at all like other cutters. Explain that one? I have used Roland, Titan and MH they all smooth out those rough jagged lines. Its kinda like its a child to some people on this forums, " My Kid DIDN'T Do THAT" well guess what. Your kid did and still does.

Bad advice. Also I see that jagged edges at are on a vector Graphtec will cut that jagged area as it is. It will not smooth it out at all like other cutters. Explain that one? I have used Roland, Titan and MH they all smooth out those rough jagged lines. Its kinda like its a child to some people on this forums, " My Kid DIDN'T Do THAT" well guess what. Your kid did and still does.

You read those same comments a lot because we start at the bottom and work up on solving issues, most of the time those simple things actually fix the problem. The most common problem we see with people that upgraded to their first graphtec is indeed using a different offset number than 0. With what you have shown it is usually too much blade expose, which of course with your years of knowledge already know about. But it is a process we start from the ground up to make sure it isn’t something simple. With your vast knowledge I am not sure what we can do to help you . . . Where did you find a new ce6000? They have been vary scarce since issues with the ce7000 cropped up.

the debate on blade angle is up to the user but for me I have exclusively used 60 degree blades in all my graphtecs and my rolands for over 8 years. That is a choice that works for me.

-

2

2

-

-

Welcome from . . . Michigan but Florida at the moment.

-

Did you ever use that printer with anything except sublimation ink where there might still be non sublimation red in the lines and head?

-

1

1

-

cutter not connecting

in MH Series Vinyl Cutters

Posted

Skeeter is heading you in the right direction. Just put the euchre hand down, grab a vernors and you will be cutting in no time.