-

Content Count

4,448 -

Joined

-

Last visited

-

Days Won

174

Posts posted by haumana

-

-

I am of the mindset - if it ain't broke don't fix it ... or the equivalent for upgrading operating systems and/or software. There's a reason why Skeeter still uses an old XP machine

If I get my machine to work with a certain software, and it functions with enough features to support what I'm doing, then I leave it be. Though, with the new Windows machine wanting to force upgrades upon machines, that's a tough workaround, because sometimes an unwanted upgrade will break some functionality in certain programs, or no longer wants to support the peripheral devices. It kind of makes me crazy, but thankfully Microsoft will ensure that my IT consulting business will thrive for the foreseeable future.

-

1

1

-

-

I don’t have any way to do this but am wanting a gift for my daughter turning 21 in a few weeks. I’m looking for one of those insulated tumblers or something like that, with some text and something about Italy on it. I’ll draw up the design, I just need someone to supply the product and put the image on it, then ship it to me.

anyone interested?

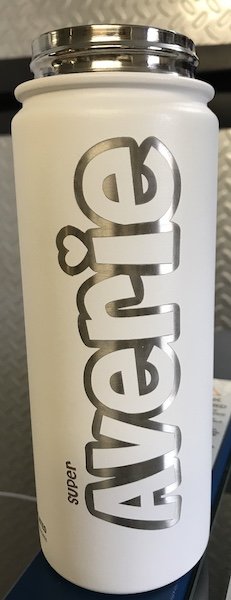

Hey Jeep - I have a CO2 Laser Machine. If you'd want a bottle/flask/rambler or cup/tumbler done let me know. I can do anything that's been powder coated (like the colored Yeti's, HydroFlasks, etc.), glass, or anodized aluminum. The down side to laser is that artwork works best in black & white format (as the laser beam is either on or off - because it doesn't do colors).

-

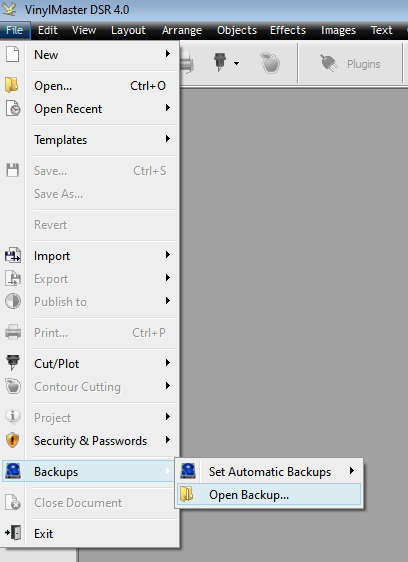

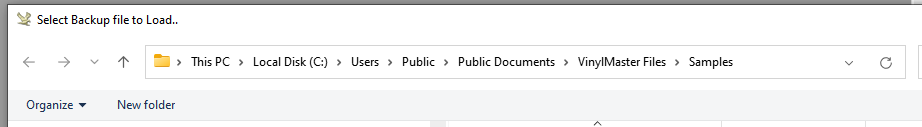

Sorry to hear that you lost a lot of your work. VM has a very basic ability to configure automatic backups, but maybe this will help.

At any rate, if you keep your artwork and working graphic files on a single computer, I would suggest either subscribing to an online backup service such as BackBlaze or Carbonite, and/or get yourself an external drive to manually backup your files periodically. When I get desperate, I will have Explorer search the entire computer for anything with a particular file extentsion (ie. *.docx, *.xlsx, etc.). It might take a while, but it might point you in the right direction. Good luck.

Where to open a possible backup file in VM:

Default location for my VM backup files:

File extension for the VM Backups:

-

This would be such an awesome tool, however, I think you might have to troll Google for Wordpress forums to get a better answer

-

It was nothing relative to the blade. As I figure after the checking all that with the blade the first time and then studying the behavior of the blade dropping and rising.

It was the motherboard. The new motherboard has solved the issue.

thank you all

thank you for updating us. it's always appreciated, and no doubt someone will find this thread useful.

-

I have been lucky over the years, clients stick to the basics and don't aggravate me with odd font requests.

Probably 80% of the stuff I've produced is straight Block (sans serif) lettering, Helvetica Bold or Microgramma Bold or some-such.

Boring AF, but readable and direct to the point. My philosophy is that signs need to be created with the KISS principle.I'm not a graphic designer. I am a sign maker. (Or to be precise, a computer-cut-vinyl sign lettering guy).

I believe in the same philosophy, its just too bad that some of my clients don't agree with me.

Not sure why it's so hard for them to believe that I don't do design, I cut vinyl. That's how I would work on websites with clients. Draw me something on a paper or napkin, tell me what colors you want, and I can totally kill the technical side and get it worked up for you, but do not ask me to design it for you, because you will not like what I come up with. Hahaha.

-

I just tell people that Serif fonts have "feet", and Sans-Serif doesn't. They pretty much grasp the concept ... then usually want something that custom that kind of falls into it's own category from dafont.com

-

2

2

-

-

Give a check when you type something in one software whether it comes with a stroke added by itself or not. Nearly all the times when the files are transferred from one software to the other, the default stroke from one software is picked up by the other as an extra width. The same thing happens when the same image is traced in different softwares. I use illustrator and it has the default stroke set to 0.25 mm or 0.01 inches. So whenever I type something or trace an image, it adds it up by the default and it comes to play when I transfer the file in flexi Sign for cutting.

I don't think I've ever run into stroke widths being an issue when it comes to fonts. But I will fire up a few different programs on PC and Mac and test out the varied font situation. I was also under the impression that font pts. were somewhat fixed - with an approximation of 72pts = (roughly) 1 inch.

-

Yup. So, for example, a word in Corel - 4" in height (and 4.873" wide) is 338.491pts. The same word in Graphtec Studio is 2.892" wide and 184.1pts.

At the same height, I'm getting very different widths, which the results only become much more pronounced the more words/letters that are in it. No stretching, or adjusting to the width or kerning.

I find the pts difference interesting, but fairly inconsequential, as when I do text, it need to be measured in height either in centimeters or inches. What truly baffles me is the difference in width, because it is vastly different.

-

So this is something I just ran into. I have a customer requesting basic text. When I enter the test in Graphic Studio (because I'm working on my Mac today), and then I did the same in Corel Draw. I'm getting two completely different dimensions, however, when I'm looking at the text in both programs, the proportions look identical. The kerning and text width seem to be spot on in both programs. There's a huge difference in font point sizes, even though the text are exactly the same measured height. Has anyone else ran into this? my mind in blown

-

Clean Cut Blades are hard to beat and last a long time. And a lot of people go with the 60 degree blade and just use it for everything. Unless you're doing a lot of relatively low detail designs, the hassle of switching back and forth between 45 and 60 is just not worth it.

That would be me in a nutshell.

-

Remove the protective plastic on the cutting strip. See if the cutting strip has any deep cuts. If there are some deeper cuts in it, you might want to flip it over, or replace it. I always have a new replacement cutting strip on hand just in case.

Lifting on cut vinyl can be caused by several things, or a combination of them - too much blade depth, too much pressure, cutting too fast, broken blade tip, etc. If you're going to cut smaller things and/or more intricate designs, slow the cut speed down and you might want to consider using a 60* blade. I personally prefer the 60* from Clean Cut Blades, they last me forever.

I believe has a trial version you can test drive before buy, so you might want give that a go.

Keep us posted.

-

1

1

-

-

Hi all,

I just purchased a Titan 3 28" cutter. I am currently trying to figure out which software I want to use. VinylMaster or Sure Cuts Alot. When I install SCAL, and then connect the cutter and then check to see of SCAL can do a roller test nothing happens. I manually selected the cutter in the settings

Nothing happens when I do the test roller function

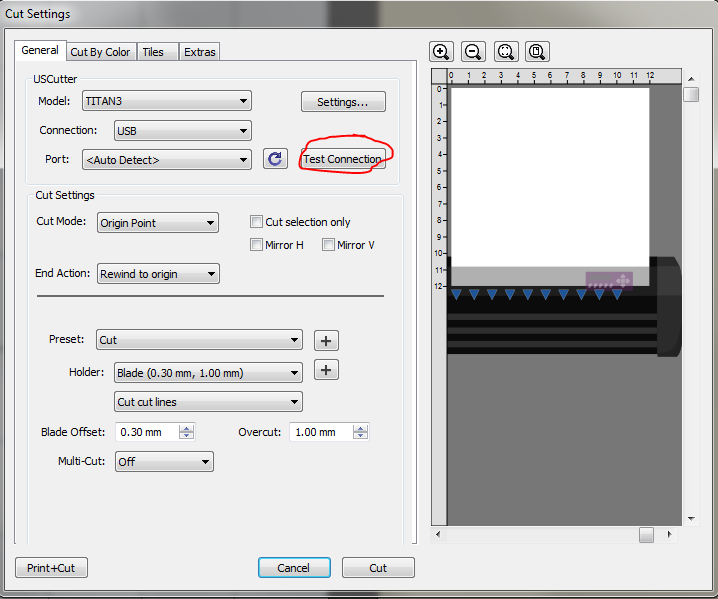

So in this screen shot, were it says "Port", you have <Auto Detect> selected, I would go into Device Manager and find out which port Windows has assigned to the cutter to, and select that port in the software. That's a good place to start. The next question is, is your cutter connected directly to your computer with a single cable (ie. not using an extension or a hub)? The cutters tend to function best if tied directly to the computer, preferably one that isn't excessively long.

Go from there and keep us posted. Good luck.

-

I am envious that you have a dedicated working space. I have to put things where they kind of fit, and work around that

The cutters are in front of my desk, with just enough room for me to load them up. On a good day I have a small table with a self healing mat to tape up. If the project is physically too big to fit on the small table, then I have to clear off the dining room table. I do my best not to take on projects that have longer runs. LOL

The cutters are in front of my desk, with just enough room for me to load them up. On a good day I have a small table with a self healing mat to tape up. If the project is physically too big to fit on the small table, then I have to clear off the dining room table. I do my best not to take on projects that have longer runs. LOL

-

-

not quite understanding the question or issue. If you select the color red to be cut, then everything that's red will cut as long as it fits in the design space and the media size at you set in your software. It will also preserve the layout so if you have a 36" design with a single red item at the very left, and a single red item at the very right, the cutter will jog all that vinyl between the two different elements. If you have multiple red items, but it's not cutting all of it when you send it to the color, make sure that all the elements are actually the shade of red, because the software will know if it's RGB Red 255 vs RGB R250, and it will only cut the one that you designate. <- That's just an example.

-

Thanks for keeping us posted. Sounds like you have some serious static management going on.

-

Super random - any chance those two elements are actually raster and not vector?

-

1

1

-

-

If you can't seem to break it apart like you would like, then copy and paste, then node edit out what you don't want to keep from each one. I do that frequently.

-

1

1

-

-

I'm a dual platform person, however, I spend the majority of my time on Macs. Right now, the top priority is getting clean cuts, so let's get this done one step at a time.

The best way to tell if the cutter is going to perform to your standards, and get the clean cuts you're looking for, is to test it across multiple software if necessary to see if you're getting differing results with the same image. If you are, then it's the software that you should be looking at.

I get that the AI plug in was a huge selling point for you, but it's not quite time to throw out the baby with the bath water. Have you downloaded and installed Graphtec Studio? I would select on design which will be your benchmark to test across the board. You know the results that you're getting from going the Mac > AI plug in route, so merge that design into Graphtec Studio and see what those results are. You can also test the design on a Windows machine. Window is not going to be you go to right now, but this is part of the process of elimination to get your machine dialed properly.

-

You cannot start blaming the hardware, until you've had a chance to test it with other software.

Be patient with dialing in the machine until you find the 'sweet spot' of blade depth, speed, and force. It was a learning process with my first cutter (LaserPoint), and another learning process with my Graphtec CE6000. It is what it is, and I would have liked to be able to dial in the Graphtec quicker because I had cutter experience, but every machine is different, so it is what it is.

If you're wanting more accurate detail, wait until your 60* blade comes in, hopefully you ordered a Clean Cut Blade.

You'll get there. Don't give up on the machine. Just find smaller designs to get your feet wet with this cutter.

-

-

On 6/14/2022 at 11:51 AM, darcshadow said:Curious what was difficult about switching material? Once you set the blade depth correctly you should be good to go for virtually all standard vinyl. It shouldn't take you more then about 45 seconds to pull one color of vinyl out and stick another in.

Ditto. I've used one blade depth, and then simply adjusted the speed and/or force depending on material and design. If i'm cutting reflective, I just keep another blade holder for my older machine and swap it out.

-

1

1

-

-

On 6/14/2022 at 1:48 AM, MrXray said:...

1. When cutting 15" vinyl the left side tends to lift up (and "bubble" for lack of a better term) while cutting even though the blade has not traveled past the material. I can only assume it's because the blade may not be lifting high enough to clear the material. any ideas or suggestions on what is causing it and how to avoid this?Is your media tenting? If so, check your pinch rollers, and make sure that they are evenly spaced from each edge (ie. 1" from the right and 1" from the left).

Does it tent on all material, or just specific material and/or width? Is the material fairly flat? I have material that has a slight curled at the width edges - which makes me totally crazy, because I can really only use it on small cuts or use it on a cutting mat. How far does the material jog back and forth before it tents? Are you leaving enough slack in your material for the entire job? Material should never be pulled directly from the roll under tension.

Another is the possibility that the pinch rollers are out of balance in terms of tension (ie. one has more tension than the other), and/or the rubber on the pinch roller is hardened so it doesn't grip like it should, and/or it could be slightly out of round - like there might be a flat spot(s) because it's not kept in the "up" position when the machine is not in use. It's usually not recommended that the tension be adjusted on the pinch rollers, but do what you think you need to do to fix it. Although, another alternative is to order another set of pinch rollers.

You can also try slowing the cut speed, so it will slow the jog speed.

Keep us posted.

Vinyl cutter recommendation for a university makerspace?

in Pre-sale questions

Posted

The one advantage of getting a Graphtec, is the software that Graphtec will bundle with it. It's dual platform, and has an Illustrator plug-in that's supposed to let you cut directly from AI. Admittedly, I just import my vector files into SignBlazer if I'm in Windows, or the Graphic Studio if I'm in Mac, and just use those two for cutting, rather than designing.

I have a friend who has a Titan 2, and they love it. I have an original LaserPoint, still going strong, as well as a Graphtec CE6000 (just wish that I got that a lot sooner ), whatever you decide, I don't think you can go wrong with upgrading to a different cutter with a larger cutting width.

), whatever you decide, I don't think you can go wrong with upgrading to a different cutter with a larger cutting width.

Good luck, and let us know what you decide!