-

Content Count

136 -

Joined

-

Last visited

-

Days Won

9

Posts posted by Scratchthejeepguy

-

-

Welcome from another SC2 owner!

-

Yeah, I think the only bundle that's worth it, is a bundle of vinyl colors. I'd pick and choose what else you need. If you buy a package deal you'll be paying for things you may never use.

-

Hi from Wisconsin!

-

8 minutes ago, MZ SKEETER said:First off, what was your plan when you got a vinyl cutter? You should have had goals already set up...What works for someone else may not work for you. You can hand a person a fully paid off business, and they can fail. if they don't have enough ambition and know how to make it work. It's all up to YOU to create your own niche' , not what everyone else is doing. That is your problem, your trying to do what everyone else is doing. I do not sell anything local, I sell to the USA. And it has supported me for 11 years. My quality, prices, and great detailed work, and unique designs bring me customers and repeat buyers.

Honestly... I didn't really have much of a plan. I have a CNC plasma cutting table and over the past 10 years or so, I've made a lot of metal art and signs, but I can't get super detailed like some of my customers wanted me to with lettering and stuff like that. So I thought I should get a vinyl cutter someday to add fine details like that to my metal work, but never pulled the trigger. Plus I have a bunch of off road trails and a gun range on my property and want to make a bunch of signs for them, so I had a personal interest as well.

Recently I had a friend that wanted to buy a firearm from me. He didn't have the cash but told me he'd put whatever I wanted to buy on his credit card in trade, so I said let's do it!

I really wanted it more of a toy than anything, but was hoping I could also make some money off it as well. If I can't... no big deal. I can use it for friends and my trail signs and add to my metal work, but if I can make some good money with it, even better! I was hoping to hear something like "Small, back window car stickers have very low margins" or "I only make T-shirts now since they are my most profitable item" or something like that.

-

I'm still new to the vinyl cutting world. I have my SC2 up and running and it's working great, but I'm not sure the best way to make money with it. What kind of products sell the best for you all?

~6" decals for car windows, laptops, Hydroflasks or smaller items

Larger car decals

Home Interior wall decals

Custom orders of business window fronts (hours or names on doors)

Large windowfront signage for businesses

Making Vinyl Stencils and painting on wooden things

HTV and making t-shirts, caps etc...

Vinyl on drinking glasses, or stencils for sandbalsting on glasses?

A combination of some of these maybe? Are there other things I'm missing that are good moneymakers?

-

Well, so far I'm happy with my purchase, but I haven't had to call for any issues yet. I will say my order arrived very quickly, and I had it up and running much quicker and easier than I thought it would be.

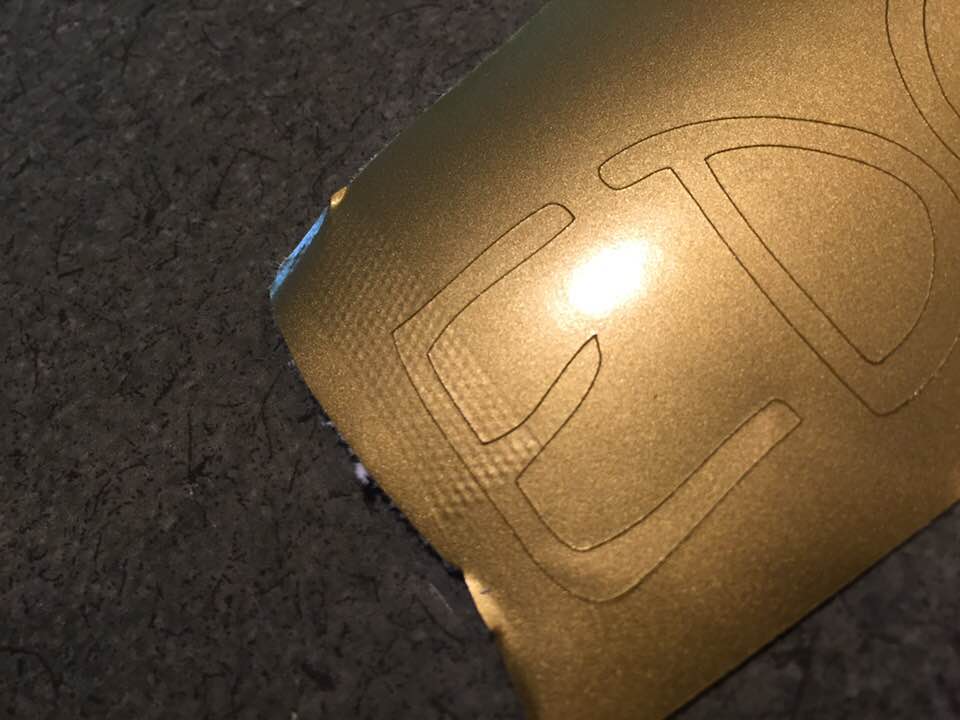

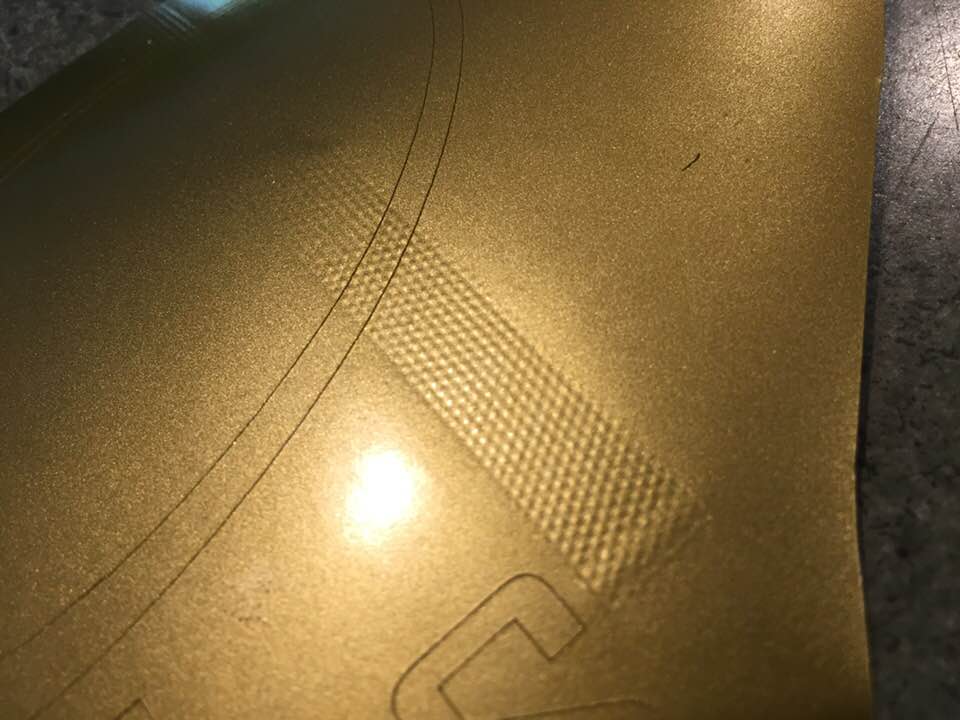

My only issue is that the roller guides leave marks on the vinyl, but I assume that's with most machines.

i guess only time will tell, but I'm happy so far. (Knock on wood...)

-

I have about 40 small signs to make from coroplast. The signs are about 8"x12" and I'll be adding vinyl letters to them. They're already cut to size using a table saw, but I'd like to have the corners rounded with some sort of radius. About a 1-2" radius maybe. Any ideas on how to achieve that without just using a knife?

-

I know that when doing a wet application, you need to give it time to let the moisture escape and for the adhesive to bond. But does the same go for a dry installation? Does the vinyl achieve full adhesion after a certain amount of time? I'm specifically asking about Oracal 651, but would like to know about most common vinyls as well.

-

Welcome from Wisconsin!

-

Welcome from another noob!

-

Lolooks great, what are you applying it to?

-

8 hours ago, signyouup said:White about a whiteboard? Nice smooth surface and and has a frame.

I'm looking for something with two identical sides to double the real estate. I bought an 18"x24" piece of white lexan and it seems to be fine. I may get a smoked or colored one for white decals someday. Seems to meet all my requirements so far and is very smooth.

-

-

I've been seeing people say to not use the plastic type transfer tape in a wet application since it won't let the moisture escape. Is this true? Can I use it or should I get some paper transfer tape also?

I'm using Oracal 651 vinyl.

-

Thanks all. I have some aluminum sheets and coroplast here that I will try. I think I'm going to also try colored plexiglass.

-

@cardudenc Your daily driver is on 38's! You're more of a man than me! Sounds like you and @Wildgoose both have some nice rigs! My main trailrider is an 03 Rubicon on 36" TSL/SX's with beadlocks, a 5.5" RE Long arm lift, 8274 winch and stock engine. Pretty basic, but it works for me.

-

1

1

-

-

My wife has a hair salon and it's very busy. I'd like to display a bunch of stickers on some sort of flat sheet that can be easily picked up, moved and looked at. I tried using one of those white foam boards but there's just a little bit of texture to it and the vinyl looks just barely "rough". I even tried some bare steel and it looks better but it still has some texture. I'd like to use something super smooth like glass, but I'm concerned about it breaking, and I'd like it to be double sided.

What do you use?

-

Well I found a spot for all my stuff. I can store my extra blades, squeegee, Exacto knife, pick, and tape measure in the bin I screwed to the cross member and upright. Then I drilled some holes in the cross member to hold up to four carriage holders, a pen holder, and a scissors. I also mounted a tape dispenser on the other side just in case.

-

2

2

-

1

1

-

-

Maybe I'll just leave them then and bring the heat...

-

1

1

-

-

Hmmm... that's the kind of answer I was hoping I wasn't going to get, but kind of expecting. Good tip on using heat. I'll try that.

-

I'm getting roller marks on my vinyl. They don't seem to be going away even after I apply it. Is there a best way to adjust those adjustments in the back?

I have an SC2 and am using Oracal 651.

-

12 hours ago, cardudenc said:well Hate to side track the thread, but since I have nothing to add. what kind of jeeps we talkn about here????

I'm wanting to eventually add a plasma table to the shop, right now I just use my hand held for the work I do n my jeep shop

Plasma tables are fun. A LOT more messy than a vinyl cutter, that's for sure! The reason I got the vinyl cutter was because I had customers want me to do very fine lettering or details on metal signs that the plasma cutter just couldn't do. I'm excited to make some cool stuff with it!

As far as Jeeps... I've had over 30 open top Jeeps in my life, currently have 9. Mostly Willys.

1 MB

3 CJ2A

2 CJ3A

1 CJ5

1 CJ7

1TJ

-

2

2

-

-

1 minute ago, MZ SKEETER said:why export DXF? .eps is the most widely used format. and will work in most any cutting software.

Sorry... I meant I just tried exporting a file as a DXF like I do when I plasma cut (my plasma cutting table uses DXF's not EPS)

I just wanted to see if I had the "convert text to curves" box checked when I draw something up for plasma cutting, which I do.

-

4 hours ago, Wildgoose said:I am not a Corel user but looking at your SVG export settings I see one that I would change. You should export all text as curves. I would actually recommend converting any text to curves during the design process before ever getting to the export and maybe you are already doing that. Some of those other bitmap setting are probably for thumbnail viewing the SVG or something because the SVG will not be a bitmap itself. Not familiar with the nitty gritty of Corel.

I AM a Jeep fan though.

Thanks for the tip fellow Jeep fan... I use Corel for my CNC plasma cutting and always convert the text to curves right after I type out and decide on a font. It makes it easier to size and edit as I'm sure you know. I've never seen this exact screen though as for my plasma cutting, I always convert to DXF. I'm assuming that by me doing it right away it's the same as checking the box correct...?

EDIT: I just tried to export a DXF file like I do for plasma and a similar screen shows up. It also has the "convert text to curves" box checked. I'll just check it now in case I ever forget. Thanks again!

-

1

1

-

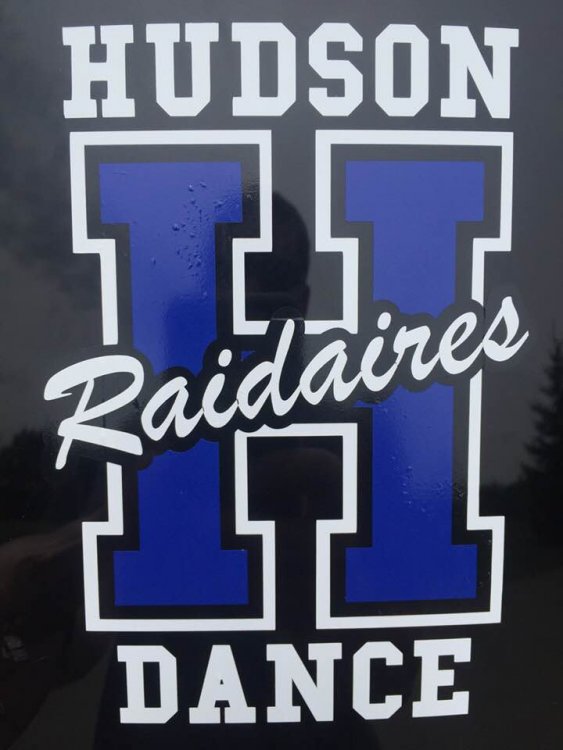

boat vinyl

in Show your work

Posted

Looks nice and I'm glad to hear that 651 lasted 6 years on a boat. Do you have any pics of it near the end of the 6 years?