-

Content Count

297 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Gallery

Everything posted by kainth.c.s

-

Sure Cuts Alot Pro 3 makes wonky cuts

kainth.c.s replied to EpicDecal's topic in Sure Cuts A Lot Pro

Are you using a USB port to communicate with the cutter? -

However, there can be another thing The pressure on the pinch rollers may not be uniform. Did you happen to tighten the tension of the pinch rollers or did something with the adjustment screws if any on the machine? OR if the rubbers on the rollers do not wear out equally. Did you happen to replace any of the roller rubber recently? I would do all the rollers at once if I had to

- 10 replies

-

- plotter

- graphtec ce6000-60

-

(and 2 more)

Tagged with:

-

How to fix my cutting edges

kainth.c.s replied to dalhartcustomz's topic in LaserPoint Cutting Plotter Discussion

Looks like your knife offset is way too high. We normally start with .25 in millimeters for a 45 deg blade and we keep on decreasing it in case it cuts the corners like you sent or increase it corners appear to be rounded or digging in -

Will the length of the cables affect cutter

kainth.c.s replied to Sarjento956's topic in TITAN 2 Series Vinyl Cutter Discussions

As skeeter said, data transmission and quality does get affected by the length or distance it has to travel. It's always better to keep the cables smallest possible -

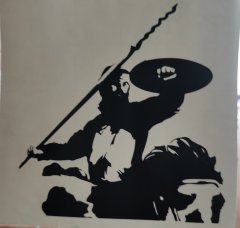

I would put up thin lines in between the stars so the stars get joined to each other. That way when you start to peel the first star, after it comes off, it will pull that line as well. So, even it breaks, you will have a bit of lifted up vinyl to grab other star. Also, it will save your cutter head from going up down up down for all the stars. Look at this picture and see the beads in the bottom. The client wanted a combination of full colour and empty beads. The same things was for the 5 holes of the instrument above that. The cutter was able to cut all the rings as 1 shape. The join line is just 0.2 mm thick. See if this trick works

-

It has been done with a household iron switched to its maximum heat setting and peeling it when warm. After the fabric went cold, I pressed it with the iron again twice within next 12 hours with a piece of pure cotton cloth in between the fabriuc/design and iron. I did another one similar 4 years ago and didn't have any complaints from the client. Hope you go ahead with the job but be careful not to subject it to a very hot machine wash and not to iron directly on to the decal. The person was too happy that he got such a detailed design being able to be made as a sticker and not a print

-

It looks like a chinese imitation of a vevor branded cutter

-

Yes it can be done. Mirror the image and cut with the shiny side down. You may have to use a bit higher downforce and slow speed I have done HTV with no issues. Have a look at this recent project While weeding, you need to sit in a well lighted room and use a hook type tool for weeding Good luck

-

Any idea about what this RTape is please

kainth.c.s replied to kainth.c.s's topic in Other Materials

No probs bud -

PCUT, laptop, and usb port

kainth.c.s replied to palladinographics's topic in Creation PCUT Cutting Plotter Discussion

As everyone suggested, go for a serial cable, a 9 pin RS232 adapter. If yours is a red and black CT 630 it would be on the same side otherwise it may be on opposite side to each other. But definitely, USB ports are not reliable. Not only they create problems in communication, but from my experience, they cause the machines to go random during cutting thereby ruining the vinyl many a times. My cutter came in with a brief set of instructions and while setting it up, I was stumbled by Three main things: 1. USB and serial port cables (I am using serial port cable and have had no issues since then) 2. Baud Rate: The value you get on the cutter screen and the value you set in the cutting manager section of your cutting software has to match 3. COM port. Try fiddling around with the different COM ports on the computer and the cutter's production manager. Lastly, try hooking a low memory Desktop to the cutter rather than a laptop so it can stay comfortably connected to the cutter Good Luck -

PCUT, laptop, and usb port

kainth.c.s replied to palladinographics's topic in Creation PCUT Cutting Plotter Discussion

Its a 9 pin holder buddy RS232 serial port -

From the album: works to show

-

From the album: works to show

-

Hi Ideally Grab some masking tape and suspend the decal while taped and mark its position on the windoww using a chalk marker or whiteboard marker. Obviously it will go over the beam. Now. with a pen or pencil mark on the decal the start and end of the beam area. I would then cut the decal into three pieces and put each piece one by one. Put the decal on the beam only if the beam is smooth enough. You may have to reposition the decal w.r.t. the other parts, so the wet application method is recommended. Start squeeging from the centre and go upto the beam. You will have a bit of overhang or extra but don't worry, that cen be trimmed later on. Hope this helps

-

Hello everybody Has anyone by chance done any stickering for the balloons? They are pretty much in trend over everywhere. Are Latex Balloons the only ones we can put the stickers on? Also, anyone has any template about the balloon sizes please?

-

Any idea about the balloon shapes and sizes

kainth.c.s replied to kainth.c.s's topic in Other Materials

-

Any idea about the balloon shapes and sizes

kainth.c.s replied to kainth.c.s's topic in Other Materials

Definitely after bud. That is why they are the latex rubber balloons and the decals need to be in low to medium tack application tape. Have a look here -

Inverse cut - name? How to re-create - beginner

kainth.c.s replied to andrewsjr56's topic in General Help

I am not a scal or VM user but I can try this thing in illustrator for you. WOuld you mind sending me the actual file? -

Any idea about the font name please?

-

Inverse cut - name? How to re-create - beginner

kainth.c.s replied to andrewsjr56's topic in General Help

Is this something you are after? 668399153_ScreenShot2021-04-25at9_51_59PM.jpg.da179ae7838e5017901bcc69c2bd7955.pdf -

The first thing I will look at is the file. Any double shapes, any overlapping lines or shapes overshooting from the joints. I also posted a video showing doubled up vector shape in an ai file a while ago. Do a closer inspection of the file. The next would be to have a look at overcuts. Are the lines overshooting from the joints or something?

-

working around the curves and sliding door rails of the van

kainth.c.s posted a topic in Off Topic Section

Was a nightmare to do around the door rails and fitting the decals to the curves but came up pretty good once finished. Both the client and myself too happy -

From the album: works to show