BossThinksImWorking

-

Content Count

142 -

Joined

-

Last visited

Posts posted by BossThinksImWorking

-

-

-

-

Thanks!

-

absolutely US Cutter. After researching cutters AND sellers, I bought my Graphtec in December from them. When you consider how it's bundled AND the $9 shipping, nobody else came close. BTW: I LOVE my Graphtec!

-

Shipping is super fast. Ordered my Graphtec on a Sunday - received it on Tuesday. Of course, I'm in Alabama and they shipped from Memphis, but still, that was fast!

-

Thanks for the curlz!

-

Have read the manual page AGAIN. Have followed every step and still it does not work right in SB. But, switched again to Robo and it works just fine. Does that make sense?

Oh, well, will try tech support tomorrow morning.

Thanks for trying, though. Appreciate your time and suggestions.

Carolane

-

turn power on

(plotter says "load media")

I load 24" roll of 631

adjust pinch rollers to edge

lock the lever

press "enter" and it measures width

(plotter now reads "2 09u +1 19 30 2"

go to SignBlazer

hit "cut"

then "cut tile"

media starts feeding

stops at about 12-15 feet

rewinds

feeds again

moves to center

cuts

Hope this makes sense to you because it's driving me nuts!

Thanks -

Carolane

-

Frustrated and trying really hard not to take it out on husband and kids. I have my new Graphtec and want to use Signblazer with it, but, it's not cooperating. Thanks to Skeeter, I finally have SB working on it, but it's not working right.

Whenever I go to cut something, the plotter rolls about 12-15 feet of media before finally cutting somewhere in the middle of the vinyl. This is in Signblazer. However, in Robo Pro, it cuts at the beginning edge just like it should. Any ideas?

This is making me crazy. I don't know what else to do next. Hopefully, one of you guys will know what to do.

Thanks,

Carolane

-

experiencing the same thing - just wondering if you ever found the answer?

-

Finally bit the bullet and bought a new Graphtec, but have to say my Pcut was great for the price. I can't begin to tell you how much I've cut with it over the past 3 1/2 years. It's been a great machine (again, considering the price) and I will keep it for a back up even now. Congratulations - now, go make lots of stickers and lots of money!

Carolane

-

Oops! Too excited I guess. It's a Graphtec ce5000-60

-

Thanks, Skeeter! I matched my com port settings and now SB is communicating with my Graphtec. I'm so happy! Yay!

Do have one more minor issue, though - and I will look through the manual for the answer if you don't know, but; my graphtec rolled several feet of vinyl through before cutting my test piece. Is there a quick answer to adjusting that?

In any case, thank you - thank you- thank you! Love you guys!

-

Thanks, found my manual and changed to HPGL, however, it still won't cut. Any idea what else must be changed?

-

I am so confused. I was trying to use SignBlazer with my new Graphtec but am not having any luck. I keep reading on here about changing the cutter to from HP GL to GP GL, but have no clue where or how to do that. Any advice would be very welcome.

Thanks!

-

So Corel X3 came free with my new Graphtec, but didn't know if it was worth the money to upgrade to Corel x5. Maybe money would be better spent on Illustrator?

-

What I needed to know. Thanks!

-

http://www.dafont.com/search.php?psize=m&q=princess

The free font princess bv at dafont.com has a blow dryer that I've used. Can't remember which one (not at the store right now) but a couple of the webding files have scissors in them.

Carolane

-

I'm on my second pcut and they have served me well, but, I'm ready to get serious and am about to buy a Graphtec this week (possibly a Roland but pretty sure it will be the Graphtec). The big question is should I pay extra to get Corel Draw 4 or 5? Or, will Corel Draw 3, which is included free, be all I really need?

Thanks!

Carolane

-

I've read reams of comments on the cutters and still cannot decide. Seems there's not a lot of feedback on the Zencut machines but what i've seen so far is encouraging. Would love to hear what Zencut owners have to say. Is there a big enough difference in the green and black to justify the extra $500?

Or should I just say forget it and get a Graphtec?

While I'm tempted to get the Zencut Green to save the money, I'd rather not regret it later, so if the general consensus is that the Zencut Black or the Graphtec is WAAAY better and well worth the extra money, I'd rather do it now.

All comments and advice is greatly appreciated.

For anyone looking at the PCut 630 machines, I can highly recommend them. I'm on my second one in 3 years and have been running a successful business with them (on facebook you can see some of what we've done at Grace's Place Wall Words, if interested). That said, I'm ready for something faster with a few more options (contour cutting for one).

Thanks!

Carol

-

Every now and then, I cut something that just won't lift with application tape. When looking for answers, I've been told it might be the application tape, wrong pressure on cutter, or even humidity. Maybe those are factors at times, but after a little experimenting this morning, I can state beyond a shadow of a doubt that it's none of the above this time.

Using the same pressure settings, the same roll of tape, and of course, the weather/humidity is the same, I got the same results with a roll of black, Oracal, 631 vinyl when I cut 2 of the same item; almost impossible to lift.

So, I changed one thing: used a different roll of Oracal, black, 631, and it lifts perfectly! It is definitely the vinyl.

Both rolls of vinyl were bought within the past few weeks and both have been stored in the same location, so it has to be the vinyl. Makes no sense, but at least I know it's not something I'm doing wrong.

-

I know this is an old thread but it's the one I used for help when my pcut wouldn't complete cuts. After reading through lots of advice, checking offset, etc., I finally stumbled on something about the blade sticking out too far. BINGO! Soon as I read that I remembered (while trying other fixes) noticing that my blade was sticking out much further than normal. I adjusted my blade and voila! NO PROBLEM! Everything works again. Cuts are closing and I can weed my vinyl. Thanks to whoever posted that little tip.

Sometimes it really is the simplest things.

Carol

-

the little extra on love looks like NYMPHETTE ( a free font, but don't remember where I got it. dafont.com ?)

-

Not Wrestling, but if you're talking about the word "Family", it looks like Aquarelle or Passion.

Carol

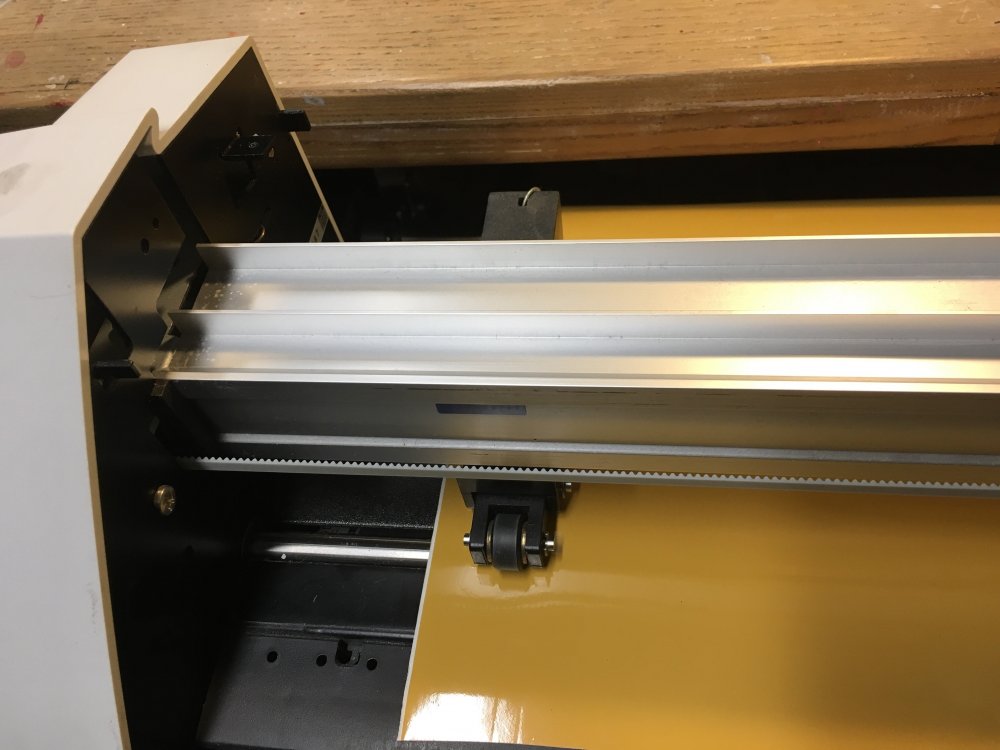

Y-postion alarm

in GraphTec Cutting Plotter Support Requests

Posted

For reference in case it happens to anyone else; When I hit “enter’ my pen block would travel to the right at normal speed, then to the left at a slower speed, hit the side wall, and stop.

Turns out it was a bent push roller sensor.

Pushed for time, I finally gave up and took my cutter to Advanced Plastics in Nashville. Dennis was great. Checked it out and repaired it so that I could bring it home yesterday evening. No need to make another 3 hour round trip to pick it back up next week.

Hopefully, this info can help someone else who’s ready to pull their hair out.

Thanks to all who post their problems/resolutions in this forum, you guys have helped me much in the past. Thanks, Dakotagrafx, for fast responses.