-

Content Count

461 -

Joined

-

Last visited

-

Days Won

9

Posts posted by cardudenc

-

-

I was doing this a few yrs ago. I ended up buying a 54" sc starter combo. I felt like being a newbie never cutting vinyl before, this would be the easiest way to make my own sign for our business . no heat press, just all the tools to start cutting vinyl. maybe the sign shop combo. but always had intentions to add htv . I even ordered htv with my initial order. so 6 months or so later after learning how to cut vinyl a friend came in on a fri wanting shirts for a biz meeting with FEMA by mon. Quickest thing I could get because of amazons sun del was a press from there. so I didn't see anything I really was interested in so didn't want to spend a lot. in the jam I ordered a $125- $150 9x12 swing arm press. I def made my $ back quickly. have now upgraded both cutter and press. with that being said, I would def do it different if I was starting from scratch again, and that is starting with higher quality servo cutter from the start. there is a difference. like others have posted , it really shows in larger cuts. I had to redo my 1st BIG commercial job. I didn't catch the error before the customer did. so that was a tough 1. starting out with the cheaper stepper cutter you will def learn all the tricks to getting clean cuts. then really appreciate a servo cutter when you get there. my upgrade to servo was with a pre owned cutter, but if doing it from the beginning , Ive seen the Titan 2 on sale at affordable price for a servo. a friend of mine loves and swears by his, less than half the price of a Graphtec or Roland.

-

1

1

-

-

this still available

-

all I have is a usb port, and not a printer port like on my sc or graphtec . a reg usb port just like on my laptop, no other port that I can find

-

bringing 1 up from the depths. what do you guys think 1 is worth now? 4 yrs later

-

well, gotten no where with this. dn loaded the driver and tried a few things , but nothing

-

-

ok, so with saying generic drivers would work. how do I set it up

-

I tried dn loading that when I joined the forum a few yrs ago. don't think I had any luck, will have to check that comp. I know I never used it.

-

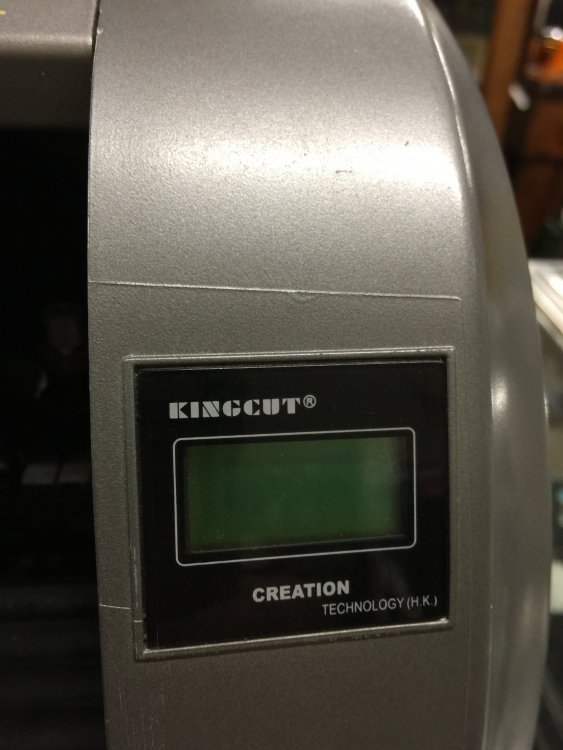

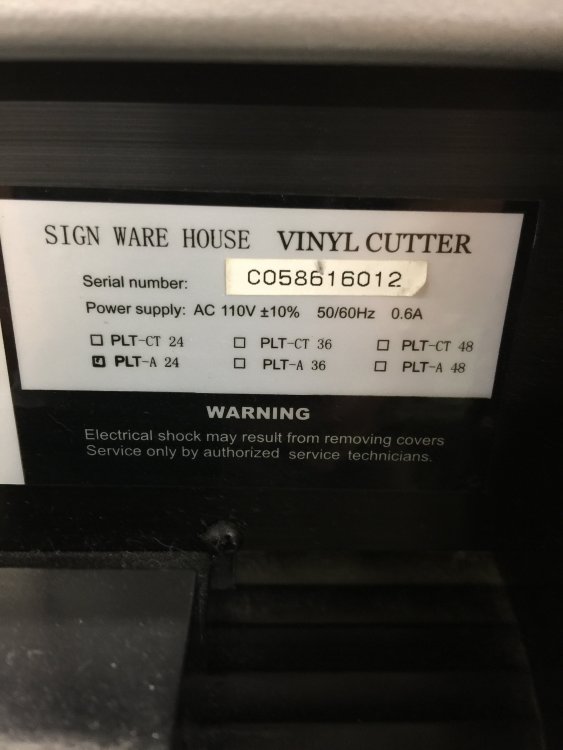

someone dropped a sign warehouse kingcut cutter by the shop for me to checkout. so looking at all markings on the cutter it looks like this could be made by creation. anyone familiar with this cutter? 1st issue was it uses a usb male to male cable. just picked 1 up, but now don't see it in any of my cut program list. im using VM cut and scalps 4

-

sorry just getting back on here. with VM ( vinyl master) on the tool bar click on the icon for vinyl spooler, looks like the space shuttle. open it and then you will see the calibration tab. again, since your local. if you need any help you can message me on here or call . I def don't know everything, but do have experience with a us cutter machine and VM. I started as newbie in 2016. knew very lil comp wise and none with this kind of software. wasn't getting very far past being able to cut out anything but txt. then asked on here for help with a logo. another member I met on here volunteered to help with the logo. then told me he started with vinyl in 2014, same thing. he didn't know much about vinyl but was comp. guy. so he told me he didn't want anyone to have the issues he had trying to learn. so has been helping me ever since. so its my way of paying it fwd.

-

did you calibrate your cutter after setting it up? that's something i didn't do for a long time. well until it showed up. i was cutting something that really had to b to spec. by the measurements on the screen i was at 24.75x5.25 but after cutting that wasn't the case. i bet it was over a yr b4 this came up, but everything i make is mainly my design, txt or whatever. so never had to fit exact, so i never checked after the cut. i make a lot of decals to sell at the store. so if i thought it was 5" long and it was + or - a lil bit it never really mattered. so if u haven't , check it out and c how much u need to adjust it

-

3 hours ago, Wildgoose said:Careful trimming is a big key to success for sure. When I started out I just whacked it off wherever and didn't pay attention. I NOW trim as square and exact as I can. I generally use 1/2" or 1/8" edges so they are consistent and if all your app tape is square to your vinyl then you just have to line up the tape and it's 10 times faster and more accurate than trying to see through the paper and measure to a letter.

yep, at the start i just cut it off however. no telling how i might cut a decal. now i almost have them all perfect square or whatever. but if multiples all r def same size. and for laying app tape sticky side dn and static creating issues, i use scotch double sided clear tape. can get it any where

-

our landlords original store is in Conway, the Wild West Western store. we r b side him in surfside.

-

ive watched a few videos on home made cnc .

-

I have a plasma cutter. so have been looking n to getting a table set up for it. as i get n to this more, it def has me wanting a cnc router set up. not familiar with a carvewright, so hitting up google now

-

ha, i was eating, shows how well i multi task when food is involved. lo.l when i 1st started i bought up several of their pre cut signs n different sizes. still have a few of those , actually a lot of them left. mainly because i started cutting a few of odd sizes out of the scrap i had left over from different projects. will look if i have a pic of the last i just made for a friend, a double sided open/close sign for her greenhouse.

it just depends, from the reg painted alum .040 to max metal. but seems i end up with more max metal than anything. kinda gotten used to working with it. ordering a sheet next week for a commercial sign job.

-

1

1

-

-

welcome , I finally have another MB peep on here.

my 1st cutter was an sc model from us cutter , and the 2 programs I use to cut with is VM which came with my cutter, but then I upgraded to scalps 4 , i save all my work as an svg file

where u at dn here? we have a store in surfside

-

1

1

-

-

main1 and where my rep works out of is Charleston sc, but had a few things come out of Greenville sc, and also have picked up from greensboro nc since my house is in NC

-

I can get u in touch with who I would call the scalp wizard, he was banned so cant get him on here anymore. which I believe hurt the forum, anyway he doesn't mind spending however much time to help u get things straight. I will ask him about the update. I haven't used mine in a couple days , so could check all the settings and compare

Quote -

I use the app tape roller that came with my combo pkg. its 28" but I have 36" tape on it now. I mount it on a folding table with furniture clamps. so nothing set up permanent . for now. the largest I did was basically my 1st big job...… our store sign 3'x12' wont ever forget it.. did it wet apply , with help

and it depends. any large I guess im using the roller the "correct" way sticky dn, for smaller stuff I have sticky up. each job I try to get a lil better. but for some reason every single time I try using paper tape I wrinkle the 1st 1 or 2.

-

hmmm!!!! will have to dn load the controller on my comp then and check that out. some parts I have found for the graphtecs are as ive read in other post on here , as expensive as buying a running used cutter. I can pik these up reasonable enough. hoping to find something I could get and fix somewhat reasonable, atleast cheaper n the end than buying a used 1 off ebay or craigslist. just not sure im ready to start collecting parts machines yet. now jeeps, I have that stuff all over the place

-

he has 3 cutters that need work for sell. the fc isn't lighting up. c the oops above will fix it

-

like any of my other hobbies I get n to, I somehow usually get n to a lil buying/trading/selling. seems like a few of u on here do the same. anyway ive found a couple used graphtecs with issues.

1 is a ce 5000-120 he says it worked fine and was hooked up thru a parallel cable. he let a friend borrow a part off of it, then when back together it wouldn't work again , says all mechanicals on the cutter work, just not the screen

the other is a fc 7000-75 he says they used it where he worked and he really don't rem what happened to it , but again screen issues, but this 1 isnt lighting up

mayb above my knowledge and abilities. but wouldn't mind giving them a try. that is if I can find pieces/parts and either repair manuals or schematics. I didn't ask if he was a member on here or not.

-

Seike SK1350T 54"

in Vinyl Cutters

Posted

I just traded for the same cutter. had art cut disk with it , well 1 of them says its a 2 disk set. my box has some other disk with it. but skeeter is correct seiki now sells the cutter with version of flexi for that cutter. and the op posted he bought it off the net, I usually suspect letgo/craiglist when people say that. I got mine off letgo. scalps has seiki t series in their cutter list. I haven't been able to connect yet, going try the dn loading drivers posted above. so its more than verified the software that came with it is junk. whats everyones opinion on whats the cutter worth