-

Content Count

1,038 -

Joined

-

Last visited

-

Days Won

74

Posts posted by bikemike

-

-

Not likely. If you could, it would be cheaper to buy a lot better cutter. And I don't know of any top of the line cutters that are Bluetooth.

You could get a rattle can of blue paint and run the cable under the carpet.

-

1

1

-

-

-

Don't know if this will help you or if you have time to make one.

-

26 minutes ago, darcshadow said:You're offset is way off. Check the manual, but I believe I've seen posted on here that Graphtecs use a 0 setting for their offset.

That is correct.

-

9 minutes ago, Dakotagrafx said:since you plan to print and contour - why not just make it easy and buy the much nicer image from vectorstock and use that - might cost $1 and save lots of headaches and much nicer version

Edit - skipped a beat there and went right to the cross - my badI do have the vectorstock one, but I wanted to use a "not so good" image to show that a raster image could be used for print and cut.

But good catch on the quality on the image.

-

1

1

-

-

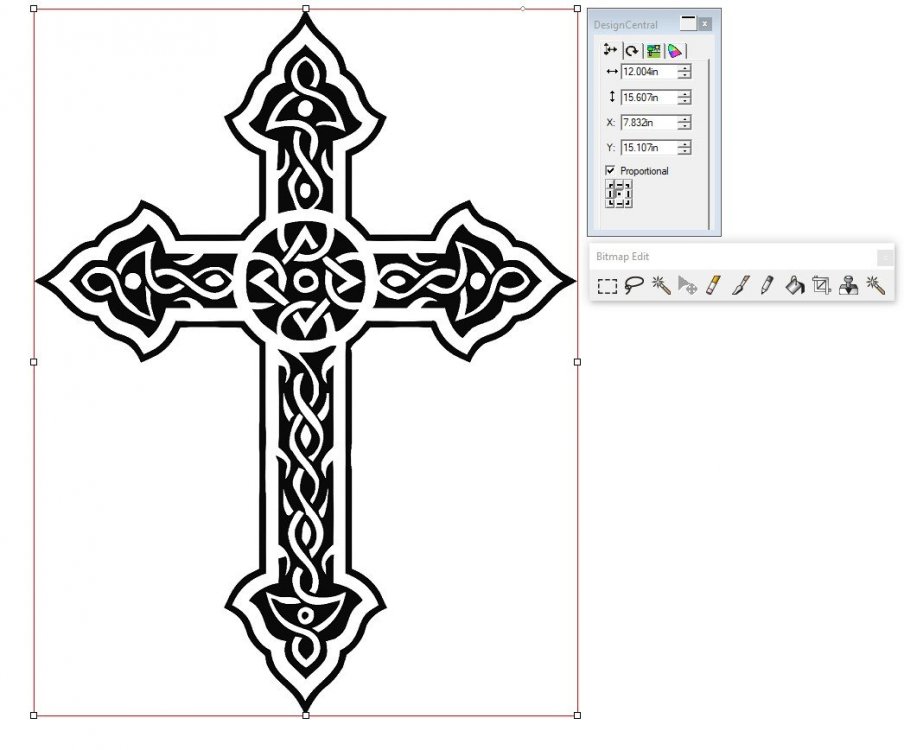

First pic is with JPG imported.

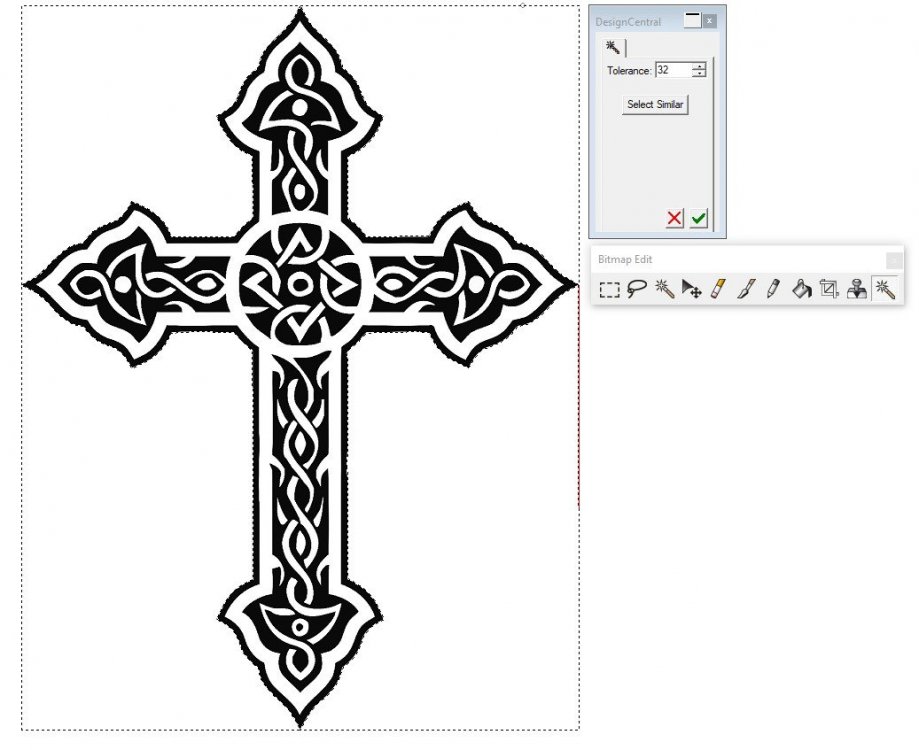

Second pic. Select make background trasperent (with shift key pressed if there is more than 1 area) Make sure to click the green check mark in design central.

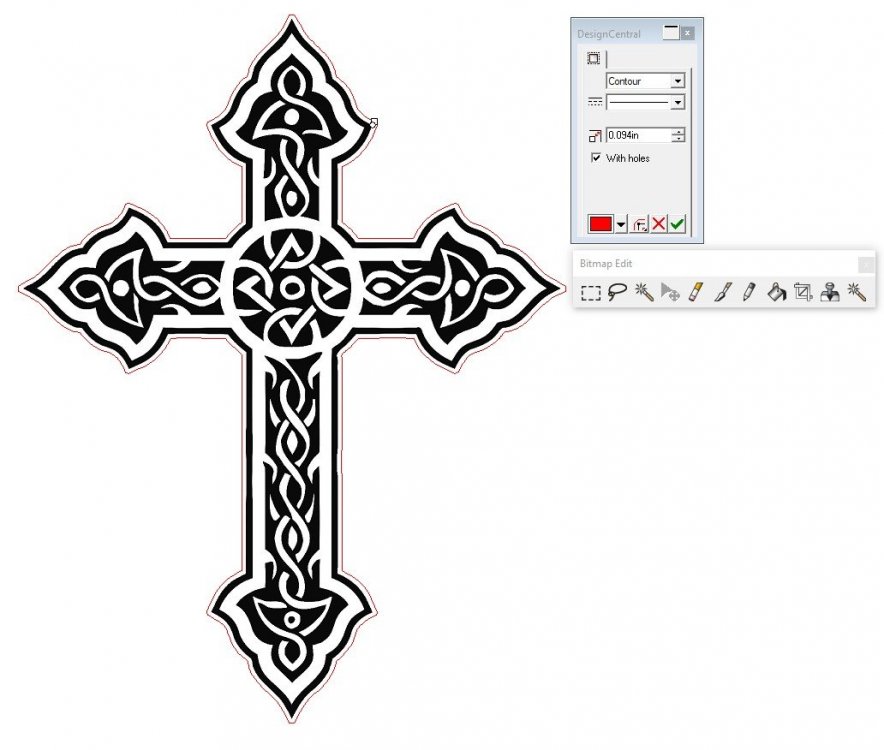

Third pic. Effects and contour cut. Adjust the contour offset or inset to your liking. Make sure to click the green check mark in design central.

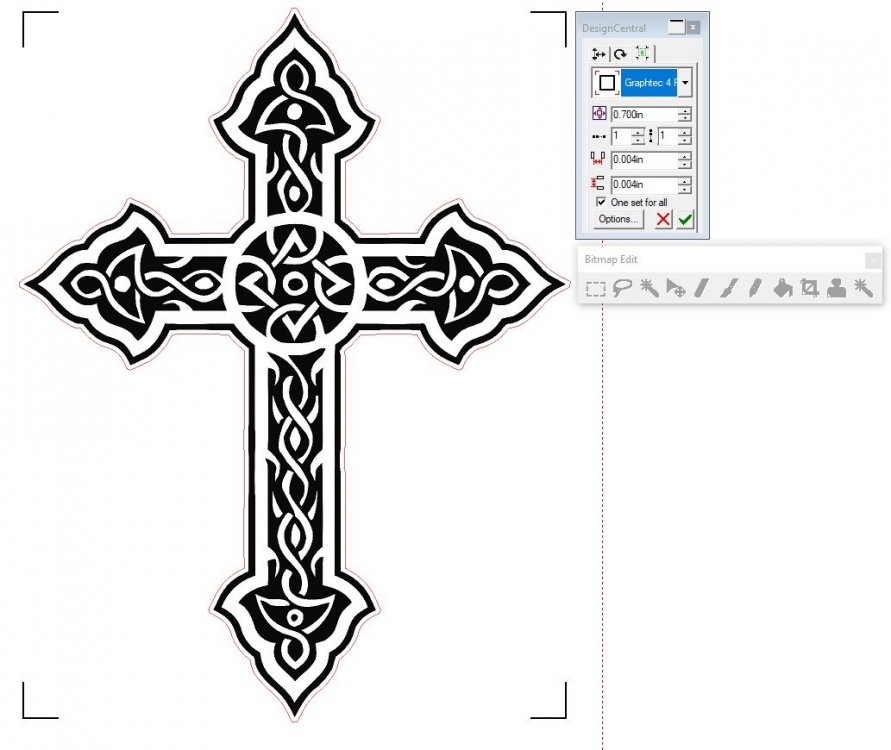

Fourth pic.Effects and contour cut mark and adjust to your liking. Make sure to click the green check mark in design central.

-

1

1

-

-

Post the file. It will contour that the way it is.

(it should)

Just to update, just tried it on several jpg files and they all contour no problem without vectorizing them.

-

Now I get ya. Go to bitmap edit toolbar and on the right, pick make background transparent. Pick all the background you want gone, (holding down the shift key) then put on your contour.

-

1

1

-

-

If you are talking about layering vinyl, just make whatever you want for a mark, change the color to something different to everything else and cut the layer color and the mark color on every color.

-

2

2

-

-

1 minute ago, LMN8R said:Will do, Mike. I was learned to do it with scrap vinyl, but will absolutely do that. Along with blade depth adjustment and using all 3 pinch Rollers, we will perform a few test cuts this evening. Will report back in a few hours with better lighted photos. Thank you all!

Scrap vinyl stretches on one side and that test and may not be accurate. Let us know if that helps.

-

12 minutes ago, LMN8R said:Mike, since owning the cutter yes, but only recently. Per instruction from Peter at USCutter, he began the troubleshooting with tracking issues. At this point, I have loosened them up to the only 0 tension I could really see which was making the threads flush with the tensioner nuts. Then counting half turns outwards until there was no slippage under firm pressure pulling scrap vinyl through them. Currently, I've tightened them up a hair more than that point of no slippage, and ensured all 6 screws are closely matched, and spring compression measures the same. There doesn't seem to be an exact formula for the amount of pressure on them, or how to make sure they're all perfectly in sync, outside of the forum-learned method of pulling scraps through...?

Try this.

Ignore the threads. They mean nothing.

Take a dollar bill and put it under one of the rollers. Pull it out slowly and adjust the pressure on that roller until it can JUST turn the roller underneath. Repeat that with the other rollers making sure you pull with the same force for all of them. That will get you very close.

And do that with the power off on the cutter!

-

1

1

-

-

7 minutes ago, LMN8R said:Mike, definitely getting the knurled impressions on the pinch Rollers in use. My photography skills are certainly lacking. The spring tension on all 3 Rollers is roughly medium-high pressure.. Guaging from the threads exposed on the pinch roller tensioner and taking measurements of the springs, they are all set the same and definitely grabbing. Will post pics of these aswell

Ok, but did you change them from when you got the cutter?

-

1

1

-

-

But, you did not say if you played with the roller tension. The would be a big thing on what you are getting. There should be marks on the vinyl.

-

That pic of your blade holder looks like a lot of blade sticking out.

I can not see any of my blade. But then I am old and need glasses to see that I still cant see the blade out that far.

Also, it one of the pic's, there is no marks on the vinyl from the rollers. Did you play with the tension on them?

-

What skeeter said IS the answer.

We do not work for UScutter and can not make decisions for them.

-

All the way back, not in the cutting part of it but in the design part.

I don't use that program, but it should be the same across the board.

-

Delete your marks, rotate your image and start again with the registration marks.

-

Does the laser on the lp3 actually read the marks or is it just to line it up?

-

3 hours ago, Mike Stephen said:Thanks. Is this still working? If not than what other laser cutter do you recommend from this link

Did you click on the link? We can do that for you, but it will take longer to get an answer.

There are others using them if you do a simple search of the forum.

-

8 hours ago, Wildgoose said:If you are trying to get text at a specific size I make a rectangle the height I want my text and then set my text on too of that the figure out how many points it needs to be. Fonts can be very different depending on how they were made and 100pt in one font does not end up the same in others.

Perfect example would be install the raleway font and type 1 2 3 4 5 6 7 8 9 0. At the same size, it is real messed up.

I have to use this font for an ongoing job and it drives me nuts!

-

1

1

-

-

deleted

-

Just guess here. Take the sheet that will cut, and the sheet that will not cut and put them together and hold them up to a light. Probably a very bright one. See if there is a difference in how close the marks are to the back edge. Are they the same?

I don't have an FC, but I do have a CE. The 4 inches may not be enough, or is very close to the limit. It is not from the rollers to the laser, but from the rear sensor to the laser.

-

If you are trying to contour cut that, you can't. I don't use VM, but there is no way it can cut that without it going out the front and off the rollers. The dotted line is probably giving you the max it can cut on that size.

-

1

1

-

-

Just a guess here, but try unchecking absolute position.

Graphtec C6000-40Plus not communicating

in GraphTec Cutting Plotter Support Requests

Posted

You can't cut direct from Corel. You need the cutting master plugin.