-

Content Count

136 -

Joined

-

Last visited

-

Days Won

9

Posts posted by Scratchthejeepguy

-

-

5 minutes ago, slice&dice said:HDS cannot be 24" tall, because your effective cutting width on 24" vinyl is just around 23" (routinely, I design anyting for 24" vinyl at 22.5", and if I need larger, I'll jump right to 30" vinyl which gives me 28.5" width to work with, or 29" if I really must).

Same thing for the other words, you cannot have 8" letters, and then stack them like that -- the math doesn't work. You have to allow a fraction of an inch between the words, and then a slight margin at the edges of the vinyl. You better have tracking dialed-in perfectly if you want to have less than 1/2" on each side of the vinyl for margins.

I was planning on cutting the HDS letters separately and having them 24" long, and like 18" wide (or whatever the scaling works out to be) I'm happy with that amount of waste, and you're right... The math doesn't work out for the other 3 words but I think I could stack two words then turn the last word 90 degrees and put it at the end.

-

The transfer tape I have is 12" wide so with overlapping one edge, I could probably get 'er done. Maybe I'll just use that since I really only need it for the 3 letters anyways. The 12" stuff I have will be fine for the 8" high letters.

Im using an SC2 which I think has like a 144" length rating so I should be fine with doing it all in one shot, but I hate the idea that I'll have about a 14" by 75" piece left over. I was hoping that it was a standard practice to nest images together to save material, then just tape them together when applying them.

thanks for your input!

-

Honestly, I didn't know that 651 came in matte... I thought that all 651 was gloss and all 631 was matte. Silly me...

Ok, so I'll definitely use matte black 651 on this job, but I'd still be interested to know the answers to my questions.

-

I have a couple of questions and I'm hoping I can get some help from you more experienced people out here. I'm pretty new to vinyl cutting as I've only had mine for about 2 months.

I have a local business that wants me to make them some vinyl decals for their walls. They are a dance studio that my daughters have been going to for the past 16 years. I want to take "friendship" out of the equation though. I want to see what you would charge a regular customer for this job, and I have a few other questions too...

It's a very basic decal they want, and I've included an image of it. The HDS letters are 24" tall, and all three total about 46" long. The HELMER DANCE STUDIO letters are 8" tall, and about 73" long.

They want the HDS to be glossy gold so I was thinking about using some Oracal 651 that I already have. The HELMER DANCE STUDIO they want to be matte black, so I was planning on using 631 for that. I tried a sample of 651 and it installed very easily, and also peeled off ok too. They need three of these complete identical signs, for three different dance rooms.My questions are:

1. Since the 651 still seemed to remove fairly easy for future painting, is there any advantage to using 631 over 651 on painted sheetrock walls other than matte vs gloss?

2. Is there a reason I wouldn't want to mix gloss and matte on a sign other than personal preference?

2. What would you charge to cut this, they will be installing it. (I'll probably help them for free since they are friends)

3. I need wider transfer tape so I'll have to buy some. I have the Transfer Rite Ultra Clear 1310G right now so I'd like to get some of the paper stuff, any suggestions?

4. I have the 28" SC2 so I shouldn't have any problems, but to save material, instead of cutting the words like this: HELMER DANCE STUDIO and using 73" of vinyl.....

I could cut them like this:

HELMER

DANCE

STUDIO

Arranging them this way would only use a 24"X 24" square of vinyl. Then they could just either apply them separately, or I could use blue painters tape (?) to attach them together in a line. Would you do that to save material, or not? The HDS I will have to cut separately unless I shrink them down an inch or so which I don't want to do.

Any input from the masters? -

You should be able to either BREAK APART or UNGROUP it, then click on the parts you want gone and hit delete.

-

I haven't had my SC2 very long, like about 2 months, but I'm very happy with it so far. Of course I've never used anything better (or worse) so I can't give any comparisons. But it seems to be in your price range and should meet your criteria.

-

Welcome from Wisconsin!

-

Thanks!

-

-

Same thing. I tried black and it doesn't want to stick to the SS very well. I'm using TransferRite Ultra Clear 1310G Medium tack, and it wants to stick to that instead. Should I be using a low tack? What do most of you use?

-

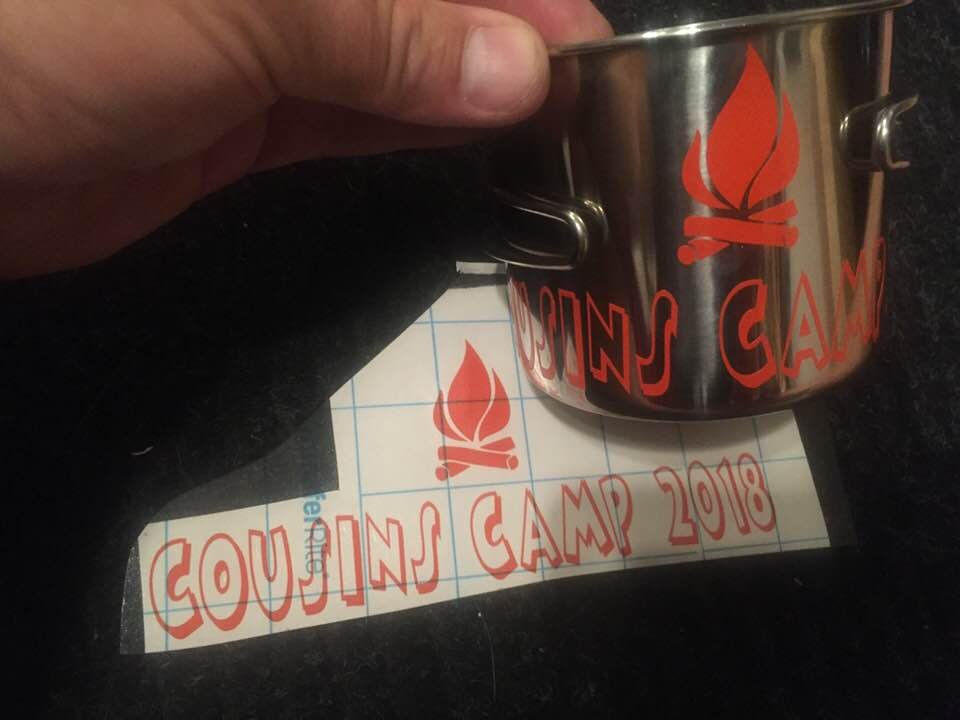

I'm having problems attaching my 651 to polished stainless steel. This vinyl is less than 3 months old, bought new, and I'm trying to stick it to those 4" round Stainless steel camping cups sold at Walmart. The cups were bought new and I sprayed them with isopropyl alcohol first, wiped it clean and dry with a coffee filter, then let it air dry for about a minute. Then I'm using a plastic squeegee and going over it several times in all directions very hard.

I'm pulling the transfer tape completely back on itself, super slowly, and I have to really help the vinyl to stick, each letter. I've used this same exact roll of orange vinyl on glass and Plexiglas before and it sticks fine. The letters are about 1" tall.

Any tips?

-

Yeah, I've tried using isopropyl alcohol first... Still doesn't want to stick to anything but the transfer tape.

-

I'm using Oracal 651 and Transfer Rite 1310G and am having problems with the vinyl sticking to the walls on painted smooth Sheetrock walls. I've heard that Eggshell finishes can be hard to stick to but I'm not sure what type of paint it is. Any suggestions to help get it to stick?

-

22 minutes ago, darcshadow said:Is that not just two rectangles?

Yeah, but one is thinner than the other.

-

Have you considered the SC2? It seems to fall between the MH and Titan. I have one and am happy with it so far. It has steppers though so it's not going to be as quiet as the servo machines, but seems to cut very well and I think it just barely meets your price requirements.

-

Welcome to the forum!

-

Welcome from Wisconsin!

-

13 hours ago, madmorgan said:....the arrow pads and such are a joke you cant move the head or rollers with them all they do is adjust pressure and speed

Are you sure about that? I don't have an LP3, but I do have an SC2 and the button layout is very similar. Yes the arrow buttons control the pressure and speed, but if you hit the LOCAL/PAUSE buttons, they will now control the head and rollers.

...at least on the SC2.

-

3

3

-

-

12 minutes ago, MZ SKEETER said:Most cutters that I have used, start cutting where the design was created at first.. I may cut a 20" wide x 90 Inch long design. When I hit cut the cutter will feed out maybe 5 feet, which is where the design was created at, then it will continue to the front and back of the vinyl to finish the entire design. I use Flexi software. If has always cut like that. But my Flexi software will also cut, OPTIMIZE cutting order. Say I break this design up into panels of 20 inches each. The software will tell the vinyl cutter to cut everything in the first 20 inches, then it will advance and cut everything in the next 20" and so on until it finishes the entire order., instead of cutting all the way vinyl end to end.

So you're saying that it's possible that my software (VinylMaster by the way) might (depending on how I draw it up) cut all the outside boxes in my picture first, then come back and cut the insides of those boxes? I know I can arrange all the cuts in order of fronts and backs, which should let me have them cut in whatever order I want, but I was hoping that it was intelligent enough to cut the design in order of what comes first on the roll.

-

I guess maybe I should ask it a different way...

If i were to cut a simple rectangle that was 20" wide and 48" long, the blade would drop and it might travel 20" across then the rollers would feed 48" of vinyl, then the blade would cut back 20" and finally the rollers would feed the vinyl back 48" where the blade would (should) end up exactly where it started. (I guess it could also go in the exact reverse order too but that doesn't matter)

But if the rectangle was 20" wide by say...300" long instead, I would think there would be a greater chance that at the very end of the cut, the blade will not be at the exact same spot it started. I could easily imagine it being like 1/4" off or something like that because of the vinyl not feeding perfectly straight.

i always thought that the better your cutter, the tighter the pressure is on the rollers, or the tighter tolerances or whatever it is, that lets it have better tracking ability and the cutter will be able to line up the start and end points better, which gives it a "maximum length" that the cutter will handle. Yes you can cut longer, but there may be some problems at the end of the cut. Is that what the max length is all about?

Now I would assume that if the drawing is segmented like it is in my picture, the cutter doesn't really care. The drawing could be 100 yards long but the cutter is only cutting like 20" at a time so it should be fine... Correct?

Yes, I know I could easily also just make I think 12 (according to my count in the picture above) separate pieces, then apply them separately... But I'm just asking hypothetically right now to understand how these machines work.

As far as memory is concerned, I still don't quite understand the limitations, or need for more of it.....

Yes the SC2 has upgraded memory from the SC, but it also boasts the ability to cut a design, then... if I'm understanding it correctly, the cutter could be unplugged from the PC and you can just hit the COPY button, where it will repeat the last cut job that it has stored in that memory. I may be understanding it wrong, but that's what I thought the larger memory was for.

Larger memory = ability to COPY a more complex job without needing to go back to the PC every time to start the cut... Am I wrong? I would think that for example with a computer printer, the memory is being used by the computer, not the printer. As long as the cutter and computer are connected, there's no need for memory. I could be wrong..?

-

I have a customer that wants a long piece cut out. It's a simple one color piece and is only about 20" at it's widest point so I'll use 24" vinyl rolls, but my machine has a max cutting length of 144" and this piece will be around 200" or more. Will this cut fine? I have attached a very rough draft of what he wants, for you to see. There will be some changes, but it will be in segments for sure.

I guess what I'm wondering is:

1. Will there be a memory issue at all with a large piece, and if so... at what point does memory become an issue? Or is memory only an issue when the cutter isn't connected to the computer?

2. Will the cutter completely cut out the first segment, then move on to the second, then third etc... or does it cut all the inside holes first, or outside holes first, then roll the vinyl back to cut the others?

I'm using a 28" SC2.

-

Nice job, they look great!

-

1

1

-

-

5 hours ago, MZ SKEETER said:I did some designs in 651 just testing them and threw them up on my painted eggshell paint, They peeled right off years later, Didn't hurt the paint. but most 651 is gloss.. You really want a matte to keep the shine down.

Thanks, didn't think of a gloss versus matte finish...

-

I think I've heard that Oracal 631 is best for painted sheetrock because it's easily removed later, but will 651 peel off fine also in the future? I have stuck some on a wall here as a test but am wondering if there will be any long term damage if I were to peel the 651 off in a few years. Deciding if I need to go buy a bunch of 631 just for painted walls...?

.thumb.png.fc64c05a82e467d002d7075020eea23c.png)

.thumb.png.cecebb7537650cc0259f155836e83c14.png)

newbie questions on my first job worth more than $5.00

in Business Practices, Sales and Pricing, etc.

Posted

Thanks for your formula for RTA. I was hoping someone had a price per inch they used and would share.

so if the 8" stacked words worked out, (which they won't I now know at 24" x24") you'd charge about 59 per sign?

also thanks for the overlapping tip with the bubbles. bubbles are for blowing...