Jburns

-

Content Count

726 -

Joined

-

Last visited

-

Days Won

9

Posts posted by Jburns

-

-

Also - if you do a lot of painting, then just use the vinyl cutter for paint stencils - you can use Oracal 651 as a stencil material too.

edit: never mind- you said you are buying the cutter for stencils.

-

Ok so I can assist with the RC decal questions. You can cut, weed and apply application tape ( least expensive) for vinyl decals. yes they can / will peel off in a crash.

Edit: you can try printing on your home based printer, (papillo paper) hand laminating and cutting- but this will not last long in RC and helmet environment. OR

If you want to Print designs- then laminate- then cut them - that would be different equipment. I currently do this for small decals using a thermal printer.

Printed and laminated decals for RC cars are in the same category as MX and football helmet stuff. Materials and machines are the same as sign shops, (print options are eco-solvent, latex or thermal) with industrial grade vinyl cutters that can cut thick laminates and vinyls together up to 22 MIL. A cold roll laminator would beneeded.

Thermal can print on neon vinyls, print chromes, etc. - which is popular in Motocross.

You would want the appropriate laminate to handle fuel spills (look at Tuff Cover UV 9) for nitro spills and what is called High Bond vinyl. Plastics are High Energy surfaces, that normal vinyl has a hard time sticking to when flexed.

-

Welcome,

I used to do a lot of RC bodies in the past. For the small quantity T shirts, you can use your cutter you already plan to buy, and get a heat press and do Heat Transfer Vinyl.

For the RC car stuff, I assume you will be using single color vinyl , right? I HIGHLY recommend a servo cutter and Cast vinyl ( Oracal 751) for the small detail needed for tiny decals.

-

1

1

-

-

Just now, mb20music said:Razepu is closer if you modify the "S" and "Y" slightly

gotcha- you guys with more experience are pretty good

-

Carre Noir Std Medium looks like the Simpli Fy font above.

-

United states should be Clarendon BT Roman, Patinio contexto is close, but will need modification

-

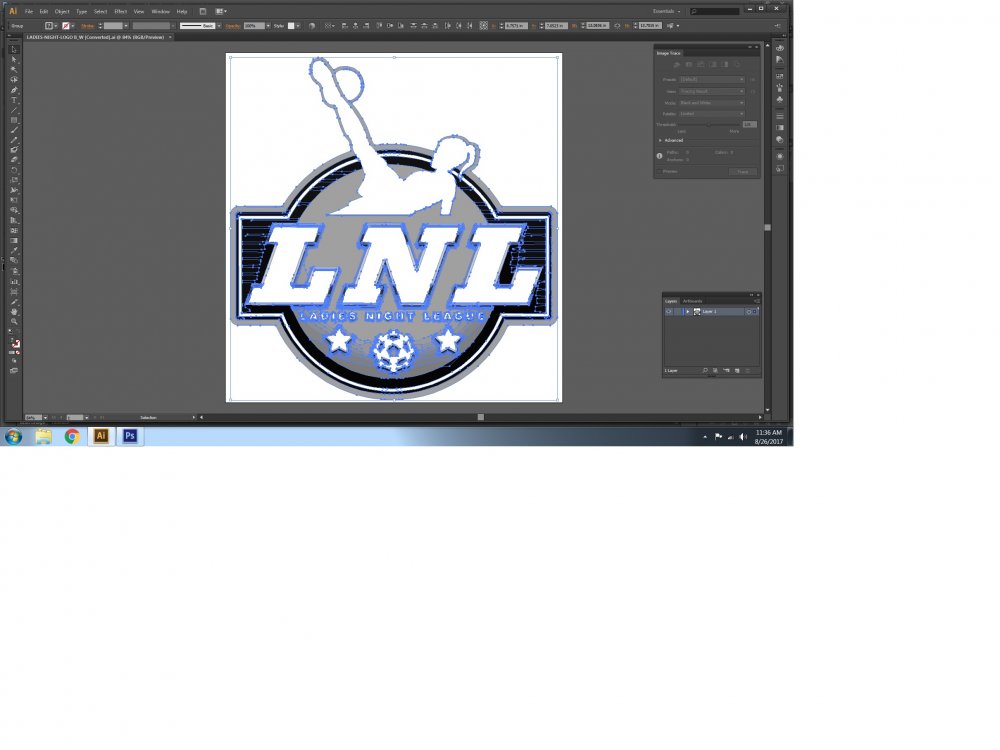

i opened it up - its already vectorized, but way too busy for vinyl cutting - looks like chromes, and some dark gray shapes, shading, that have been traced, dark traced shapes next to the "L"s..,

With some time - you can delete all the items you don't need and get the look the customers wants. Here is a screenshot. Or I am sure there are members who can clean this up for you.

-

Nice!!

-

1

1

-

-

Dry application is risky for a layered job - you cant move into position - No I would not use a heatgun.

Your customer needs a better paint job before you do any more work.

-

2

2

-

-

I need to redo the blue bit. But as I tried to peel the vinyl off, I noticed it is stripping some paint from the side where he has done patchwork. Please advise:

I have read that some guys wait weeks before applying vinyl ( cast or proper automotive vinyl) to newly painted vehicles. Sounds like the paint was junk anyways.

-

LOL!! That's awesome

-

welcome!!

-

well, the Tripp-Lite above is the best adapter. But you can give your insignia another try- Either the driver came on a CD in the box, or you can go to the manufactures website and download it.

Are you using "THE" serial cable that came with the machine? reason I ask there are two types - Null and straight. Most likely it needs the NULL cable.

-

2 hours ago, Wildgoose said:Have you looked at the font zoomed way in or in wire frame mode? Some fonts are not smooth. We are just starting from square one and making sure you don't have a bad file. The reason for this emphasis is you say it cuts flawless otherwise. Most likely the font if everything else cuts good.

We really need to see the image in wire frame mode, to see the actual nodes. this will rule out your file. Your image above is filled mode.

We think its the file because you state everything else cuts fine.

-

You will have to check a few things to start:

1. make sure the USB-serial adaptor shows up in your device manager, and adaptor has the driver installed. (no yellow triangle warnings

2. check your software, make sure it has the proper port chosen (same as your converter).

-

1

1

-

-

Can you post a short video clip?

-

Hi Guys,

So I use a Gerber Edge printer. The principle is thermal transfer- the ribbons are laser heated or transfered to the vinyl, then the shapes are contour cut with a plotter. They were more popular several years ago for sign shops, until the rise of solvent inkjets ( Roland, Mimaki, etc). Pros: basically no maintenance, can sit for months, and in most cases no lamination needed. Cons: width is smaller, photo quality graphics can't be achieved, and cost of resin ribbons higher than inks- (in most cases- I buy my color ribbons used). They are workhorses, and will provide 95% of whats required for basic decals.

In the last three years I have owned about ten including the smaller plotters (GSx, GS15 and Envision): buying, selling, repairing, etc. They do require a RIP software ( Flexi or Gerber preferred).

Send me a PM if you have more questions.

-

1

1

-

-

-

Looks great- for grounding I have ran automotive 12 or 14 gauge wire with the little connectors that are crimped- hard to explain without an image.. but you remove a lower screw on the cutter, sand thru paint- place connector attached to wire - the re-insert screw.

Other end of wire goes to grounding source. I have been using these - it's an aquarium grounding probe- connected to your outlet. The prongs are plastic that go in the outlet

-

1

1

-

-

I agree with Dakota...

also that little "j" is the blade setting it's orientation before cutting the design.

mine sets that "j" outside the design before it starts- just to the right outside the origin. I don't have your manual- specifics may be in there

-

welcome from Denver!

-

I think the mimaki's are nice machines - BUT the support here is much better for Roland or Graphtec- parts, blades, rollers, tech support-.

I would go Roland or graphtec and be done with it.

-

1

1

-

-

Man I just finished it for the OP in eps and AI formats -- Primal is right though!!

-

You may also try this:

ENTER ....................... It will define the settings.

The plotter is reset by pressing the [ORIGIN] key and this key simultaneously in the first

screen of the MENU mode (MENU screen).

It will display current cutting area when the [ENTER] key is pressed in READY status.

Go-C Graphics

in Show your work

Posted

Go-C,

If you don't already follow, I think you would like the engravers journal- their latest issue looks at displays like yours

http://www.engraversjournal.com/3dissue/de2017-09/