Jburns

-

Content Count

726 -

Joined

-

Last visited

-

Days Won

9

Posts posted by Jburns

-

-

-

Well, you need to purchase a legitimate copy of Flexi Pro software.

-

1

1

-

-

(Oops duplicate)

-

Also is your security dongle connected to the computer? The perfect repeating lines look like trial version

-

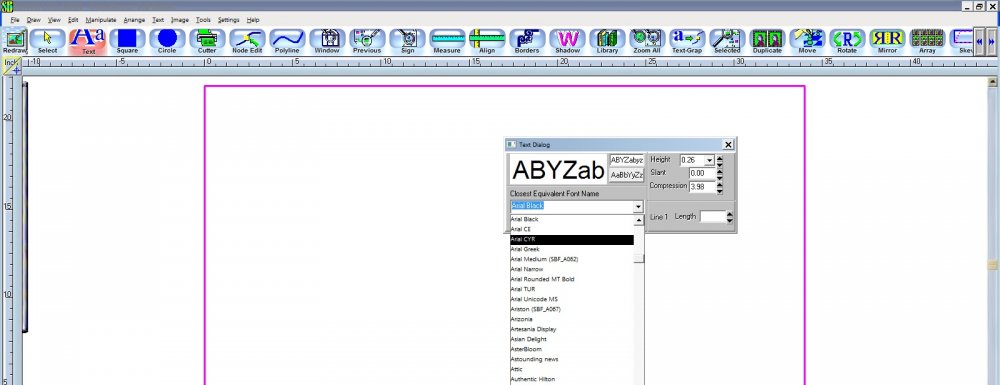

I think the BOLD version and italic versions should be installed in your Windows system Font file, before you see them in SB?

-

I would start with loading the material square-- I like to place my hand in the middle of the sheet while loading, provide tension off the roll then slowly lower the pinch rollers. This kind of squares up the feed.

Next unroll the job length behind the cutter---or provide slack for the job. Slow down the speed, check pinch roller pressure, -- add a few nodes in the corners of the design so the cuts meet-up.

uscutter say max length is 12 ft.

-

Welcome from Denver! ( well, highlands ranch - south of denver).

-

I really like the reflective. -- that logo makes me think of a body builder / muscle guy flexing.

-

Tell us the cutter that you are using, and method of connection ( USB or RS-232)? Are you cutting tiles due to large file size?

-

Inkskape is a nifty tool for sure.

Check with the libraries in your area. My library offers free Lynda Access with library account

-

1

1

-

-

Serial ports are almost always COM 1 - Open your device manager, and look at the port drop down menu to verify.

-

nice work!

-

17 minutes ago, mb20music said:I believe any NULL MODEM serial cable would work...

Yep!

-

Do you see the connection - next to the USB plug on the cutter- It has 9 pins - match that one to your port on the computer - note may require original PCUT cable.

-

that machine has a tiny memory.

Are you using a Serial to USB connection, ( see threads containing keyspan adaptor) or a serial port on your computer? this would "regulate" the flow of the file.

-

14 hours ago, jep8fan said:Will the Edge work for apparel transfers?

They used to make color foils for transfer, but I think they discontinued them-- I don't see them in the catalogs-- besides the plastisol, HTV, and screen methods may be better/

-

1

1

-

-

Yes- if you have Flexi sign pro- in rip and print window- set the contour cut for the graphtec- you also set the crop marks there also.

the check the box next to the graphtec in your production manager

-

Do you have the artwork done- ready to print? I would be willing to print a free sample for you - so you can see if the Gerber Edge would work for you.

-

1

1

-

-

I agree- it is pretty slick- a copy came with my Omega software upgrade.It was "free" after I paid 1,200.00 - LOL

-

1

1

-

-

I don't need it - but if you are in Colorado, and want a large layering table- here you go!

-

Are you connected thru USB? If so this machine has a hard time accepting multiple jobs at once. Most people ( and myself) used a keyspan USB / serial adaptor for that machine.

-

3

3

-

-

-

18 hours ago, kainth.c.s said:Hi

Thanks for your valueable input brother.

I couldn't get the saying " the machine doesn't have to "tug" it thru the rollers ". Please tell what it means brother.

Regards

Singh

So basically, dont let the machine unroll the vinyl roll- you should let the length you need to sag behind the machine. Its hard for that drive motor to pull - or unroll the material by itself.

-

3

3

-

-

Hello,

yes that cutter may have trouble closing cuts at that length.

you can assist it with unrolling the material , and make sure the machine doesn't have to "tug" it thru the rollers

-

1

1

-

Merry Christmas

in General discussion

Posted

Merry Christmas!!