Fbomb

-

Content Count

339 -

Joined

-

Last visited

Never

Posts posted by Fbomb

-

-

Want To Trade some navy Spectra Eco-film I have...I have about 3 yards maybe more, looking for kelly green and orange heat transfer vinyl...But open to other HT colors. I also have black Eco-film to trade if interested...

-

Did you use their template pack or did you create your own layers off an image you had? If you used an image you found, mind sharing the image so I can create the layers.

Good work BTW!

-

I'd love to get X4, but I use a few different PC's...Only one has XP :-

Mine works no problem in 12...I even use R.A.V.E, Corel's animation program.

-

I mainly use 50/50...But I went with Hanes 6.1oz. 100%. I really like them and use them a lot more now. It really depends on you client...In this case it starts with you and what you like, but keep in mind your demographic...theres not a huge feel difference btwn the 2 but you might want to look into the American Apparel soft shirts. I don't really care for them, but thats just my personal preference. Also, they cost more!

-

I still use Corel 12 with Trace...It works great, but with any program, it all depends on the original graphic quality! If you are familiar with Corel, it's definitely worth stepping up to. Trace is a CorelDraw plug-in, so click a button in Draw, it opens Trace, perform the trace to your liking and close Trace, it then drops it back into Draw...

-

Pro work John!!!

-

fbomb whare is Dub c in pa. iam in dover pa. just north of york.

Dub C = W.C.= West Chester...West of Philly.

-

Good stuff! The motorcycles tripped me out when scrolling the page down

-

The punched vinyl I have has the vinyl punched too..So I just put the rollers half way on the holes. If the liner was exposed, I would not!

OT funny story about chads (punch holes)...In our flexo plant, we run large sticker jobs that we provide punched...Needless to say, there ends up being chads EVERYWHERE! One guy at work that pranks ppl got some payback from us one day...We funneled an S-load of chads in he car vents and cranked the fans to full blast...At the end of the day he started the car, fans kicked on and confetti flew everywhere!!! We all watched and yell "Happy New Year" when it happened.

He said for years after he'd be driving with the air on and a random chad would float out every once and a while...

-

bump...

No one???

-

Ok. Dump question!

When I got to cut this. Should I just cut each individual line and line it up myself on the sign, or cut cut all of this on one cut. I know it would save a lot of vinyl if I do it each line, what do you do?

If you are doing one sign...Just do it all together and be done with it...If you were doing a few it might make more sense to gang them to fit less yardage.

Do you have 24" wide stock? b/c you might have to do it in 2 pieces...

-

I do both and fight this question a lot...I'll focus on the pro's of each...

HEAT PRESS:

The hassle to burn the screen, clean the screen and reclaim it is my biggest factor...That and size/complexity of design plus # of colors. If someone wants a simple design shirt 50-75 might not be that bad to press. If they want it in 2 different colors (say 30 red on white and 30 white on black), its easier for me to cut/press than to print, clean, change colors, print. That is for an easy design.

You can press on a wider range of products...Jerseys, bags, etc...Not that I can't screen print on them, but it either involves a specialty ink (or ink additive) or special platen to hold the bag or whatever...

It is easier to press light colors on dark garments...Printing can involve another screen to put a white underbase or need a few strokes (print/flash/print/cure)!

1 off clothing...I started with screen printing and my friends would ALWAYS say, "make me a shirt that says...blah,blah,blah"...Followed by "I don't care how much it costs"...Then I follow with "Lets see, $50 for the screen, $20 for ink setup/break down and $6 for the shirt...But for you, I'll eat the ink setup charge. $56 for the tee shirt". My friends stopped asking me, until I got a heat press.

Both offer cool effects...But vinyl wins with ease of reflective, foils...But printing can be cheaper to produce (but more fickle)...Vinyl offers pattern material (i.e. camo) which is cool, but I am not crazy about the feel of patter vinyl...

SCREEN PRINT:

Once the job is set up, you can rip through printing them. You don't have to align each design like you do pressing. Which can save you time and make you more profit.

You can print finer detail, halftone and process (full color).

The print won't crease and has a softer hand...SOMETIMES.

-

He asked if he could reward himself with a genuine Les Paul guitar....I replied that maybe my new press would earn me the money to get him that guitar! ;-)

Hey...Maybe you man will become a rock star and earn him the money to get you that press!

-

I've done this and got a line between the 2 presses...Not that noticeable to the "untrained eye", plus it was a white graphic, so that probably didn't help!

-

No sweat!

-

Looks real nice...I would try putting "over the hill..." below the quad and see how the quad looks on top of the "hilled" text...Then maybe put more space btwn "Topsy Store" and peak the riders helmet btwn them (just a little bit). See how that looks?

-

See if you can get the paint code, then translate that into a PMS # (Pantone Matching System). A lot of catalogs have that PMS# next to the color. I am guessing PMS 427C. Oracal "light grey"

-

-

Very nice projects I liked all of them!

Thanks!

-

I have a job that wants showroom banner stands (the vertical ones). This is my first time dealing with them (the stands). Any tips or advice on them? I was looking at Stanza 31"x70" (that is close to the size I need), but it seems unstable...the Risor seems like a good option (both stand through Fellers).

Can anyone help with pros/cons of pole pocket required vs. grommet required vs. snap in? Or their experience with banner stands!

Thank you!

-

Hey Fbomb

Could you post he EPS for the Pirate? Thanks

JW

Yeah, it's on my home PC though...So I'll have to post it up tonight.

-

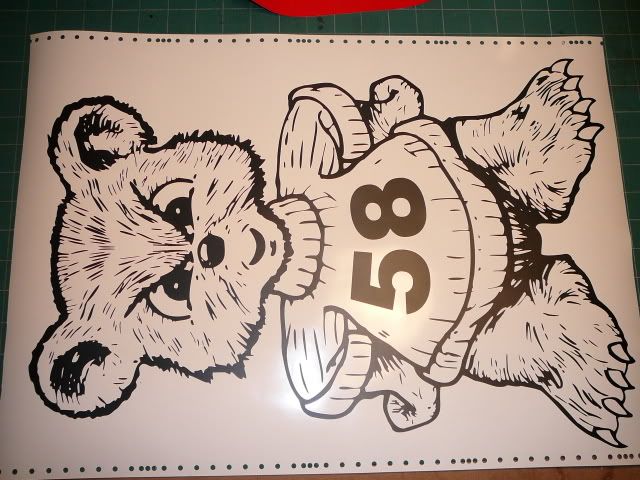

That bear is awesome!

How long did it take to weed?!?!

Thanks...It wasn't as bad as I thought. The face was the hardest and made be cross eyed. But it didn't take that long. I was doing it during an up all night crack binge getting gifts ready on Christmas Eve

and couldn't gauge time too well.

and couldn't gauge time too well. *Or at least it felt like what I guess a crack binge would feel like.

-

^^^Oops LP24...

-

My favorite! My pops high school mascot.

Photorealistic T-shirt previews

in General discussion

Posted

Cool thanks...I'll try to find an image and try to make the layers myself.

Question, do they provide Corelphotopaint files or do the PS files transfer okay in PP? I assume you use Corel b/c you have X4.