-

Content Count

21 -

Joined

-

Last visited

Posts posted by fokkerdmr

-

-

Uninstall/re-install doesn't fix the problem. Reboot, etc, same. Tried Compatibility Settings - to XP, no change.

Sigh. Dead in the water. Frustrating.

Yes, if we could end up getting the source to SB, it would be great to at least fix up some of these nits.

-

Thanks, I'll try that. It was working great in Windows 8.0, just not 8.1. I'll post on my findings.

-

It's old by software standards, I guess is no longer being updated, but I've been using it for a few years so I can knock out most any design pretty quickly. But, I had to do the Windows 8 driver trick to get it working, but my computer updated to Windows 8.1 automatically last night. Now, every cut (or just moving to Max position) crashes SB. Does anyone have SignBlazer running successfully with an MH MK2 on Windows 8.1? If so, what's the trick?

Just thought I'd check before I burn up hours trying to troubleshoot the software once again.

-

We did a production run of replacement arms this week. They are in stock, ready to ship for anyone else having the problem. Using these arms, I have improved the overall cutting performance, not just eliminated the cutter holder creep that used to happen. You can e-mail me at m51@msn.com for more info and photos.

Dave

-

Finally the arm broke. The problem is that the arm was tight - but the cutter kept creeping up. I'd tighten it just a hair more to keep it from creeping, but eventually, the arm broke. We 3-D printed a new arm that has a slot in it to hold the pen in place, rather than simply relying on friction to hold it down. Seeing as USCutter is out of stock on the replacement arms, I wonder how many people would be interested in a replacement arm that holds the pen captive vertically without requiring so much pressure?

If I have problems after 4 months of "hobby" use, I have to believe I'm not alone in this problem.

Dave

-

Offset for those blades is set at .25

-

Hmm, interesting. Blade depth is one of those things that I don't like changing around much, because it seems like I don't quite have a good formula yet. Which means I can mis-cut material (generally not deep enough).

Cutter speed is down at 120mm/s.

-

Fresh blade definately helped out. I also dropped my cut pressure to 140g. I think in a few of the places where I have rounded corners, they're even better, so I'll keep plowing away in SB and see if I can eliminate them altogether.

-

Good question. I'm using a 60 degree blade. Its relatively new, only been using it for non-production (home) use for about a month.

-

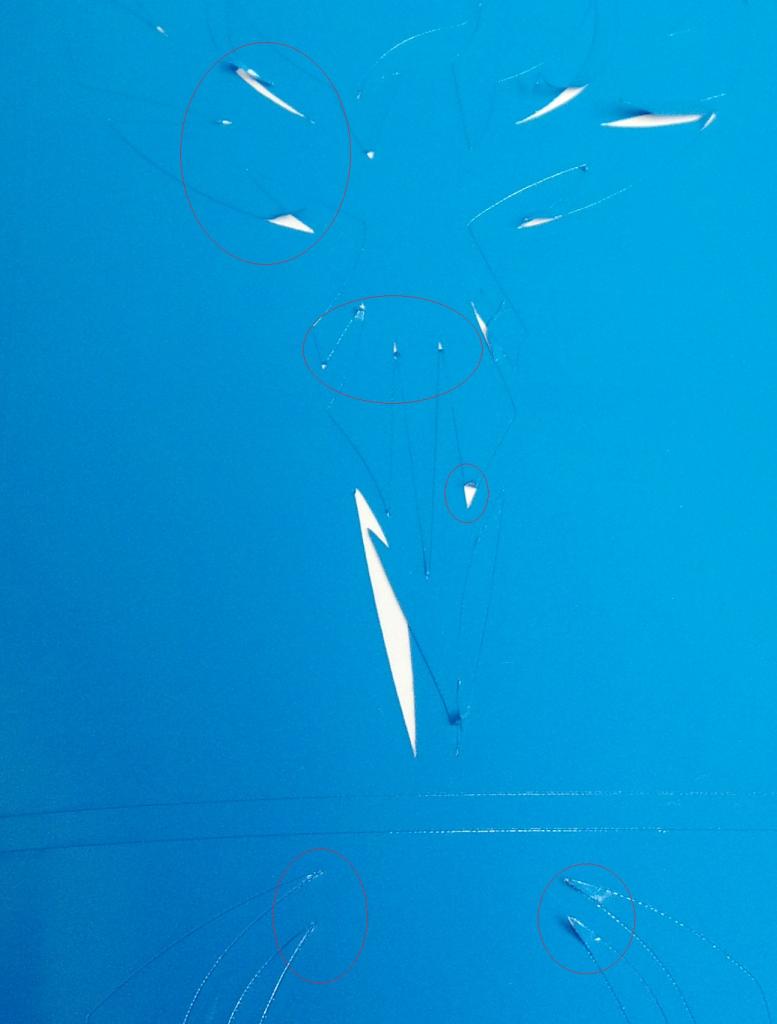

I have a vector that has some very "sharp" points. See attached .SBD

Almost all of the interior and exterior points are not being cut without the vinyl lifting. See attached .JPG for a photo of one attempt.

So, I'm wondering what the best way to handle this is?

I've started converting the sharp points to rounded points in hopes that the blade can spin around without pulling up the point. But, I'm open to other ideas that folks have about how to handle this type of graphic. Could cutter settings help? (faster/slower/offsets?)

Thanks in advance.

Dave

-

Sent you a PM 211 Grafix.

-

Actually the cuts have been fine. I typically keep tightening it down until it stops creeping up, and if it does creep a little, I take the cutter offline, push it down and then put it back online to keep cutting. It's not at all like the cutter is loose, it's in there tight, just not tight enough I guess.

-

-

Looks like you have something odd in the vector. When I imported it, it was goofy. It looks like a typical vector created after vectorizing a bitmap. I find that there are typically way too many node points that get created when vectorizing. I usually go through afterwards and clean them up and remove more than 60% of all the node points.

Try the attached one, see if it works for you.

-

I have an MH721-MK2. Loving it!

But, the cutter blade slowly creeps up out of the holder as the cutting goes on. I know that I can tighten the cutter holder, but being plastic, it just seems like it's a relatively fragile part of the setup. I don't want to tighten it so far that I snap it.

So, is the wisdom of the experts to just tighten it down, and it really won't break? Or, is there some little bracket that can be slipped over the blade holder and clamp to ensure it doesn't creep up? Any other "tricks of the trade" ?

Thanks in advance..

Dave

-

Gotcha... Found that... Testing now

..

.. -

Yep, did exactly as you suggested. Made several cuts in the vinyl and adjusted the cutter depth (offset) until I was getting no mark in the wax paper.

-

Interesting. I'd not tested the blade cut depth that way, and have been wondering how to get the right balance between blade depth and cutting pressure.

So, doing your test, 150g of pressure was too light to cut the vinyl all the way through. 200g was sufficient to cut through, and left no trace of the cut on the wax paper. Testing 300g, 400g, 500g, and 600g showed increasing cut depth on the wax paper. The blade still hasn't cut through the wax paper at 600g. Now, I'm starting to see a bit of rise on the blade holder as it cuts. I can crank down the brass knob for the holder, but that just seems like it's asking for trouble at some point. I really don't want to tighten it past the oh-no second. Is there a "best practice" for tightening down the holder?

Since the cut pressure maxes out at 600g, should the balance of cutter blade offset and pressure be optimal at around 300g of pressure? Or, does it really vary depending on the vinyl material being cut (I'm using Greenstar intermediate calendared).

Thanks,

Dave

-

Been having a great time with my cutter. However, I've noticed that many of my fonts have a small piece of vinyl that is left between where the cutter makes the initial cut, and it ends the cut. When I weed, the letters will sometimes get pulled up and I have to use my weeding tool to hold them in place. Some letters are worse than others. Interiors of letters (like the cutout in a "d" or "o") tend to have the problem.

Is there a setting either for the cutter (MH 721-MK2) or for SignBlazer that will help? Or is this just "part of the gig?" I've used the SB_ fonts (assuming they'd be optimized for cutting). But maybe there are "worse" fonts for this problem than others.

Any advice or tips to share?

Thanks in advance...

Dave

-

Thanks for posting the updated version link and the patcher. Much appreciated.

Dave

SB - the software I hate to love and love to hate (Windows 8.1)

in SignBlazer

Posted

Yep, thing is, I've already done this once. So, buying another computer would be "dedicated vinyl cutter printer #2". I thought that I'd be able to stay on Windows 8 without ever going to 8.1, but alas, that was not the case. So, I will probably just go back to Windows 8 and turn off Windows update. I don't like the security risks of doing so, but it's probably the only way. I could go back to Windows 7 as well. But, more than anything the it's the principle of buying an old computer and OS to support SB.