Kristof

-

Content Count

72 -

Joined

-

Last visited

Posts posted by Kristof

-

-

14 minutes ago, MZ SKEETER said:Have you tried rerolling the material back the opposite direction? And leave it like that for a bit? I do that with vinyl and hold it for about 10 minutes. It will lay flat then. Not sure how that would work with magnet.

I have not, but I will keep that in mind.

Ok, so I put in the blade that came with it and set the depth so that it would just scratch the surface of the magnet, and a 50x50 square is coming out as 39.64mm x 39.64mm.

Not sure what I need to do to change that?

-

4 minutes ago, Dakotagrafx said:for the red blade holder correct?

Yes, I had to order that as well

-

37 minutes ago, MZ SKEETER said:Until then , learn how your cutter operates. Make sure it will work with your software. I turned my media sensor and pinch roller sensor off on day one. Media sensor measures the width of the vinyl. I don't need to measure the vinyl. The pinch rollers have magnets in them so you can't cut past them, unless you use EXPAND. I turned them off so I can cut right next to the vinyl edge. Less waste. Your welcome

I've already figured out that I will have to cut the material with the liner side facing down since the magnet sticks to the platen infeed and outfeed alot, didn't have that issue with the 'cheap' titan 2.

In hindsight I would've told my manufacturer to roll the magnet with the magnet side facing up for easier processing.

-

24 minutes ago, MZ SKEETER said:Great, People just don't understand how much better these cutters are built until they see for themselves. That Titan 2 to that Graphtec is night and day. This is why we brag about our Graphtecs. You really do get what you pay for. Yes, they are higher priced but they are a very high quality machine. I have owned my FC7000 since 2008 and I have never had a problem with it. NEVER!! I hope the FC8600 works out for your project.

Thank you; I'm still waiting on the CleanCut 60º metal blade to arrive before I will know if it works out.

-

I just received the new Graphtec; I must say the quality of the unit and packaging is miles better than the US cutter stuff

-

2

2

-

-

I got the Graphtec cutter new from ebay, so looks like I'll have to try to make it work with my Sure Cuts a Lot

-

4 minutes ago, MZ SKEETER said:I know mine came from a Cloud. What do Cloud files say? You can contact SAI.

Where did you get this? Did UScutter send it to you?

I got it from Graphtec's site here: https://www.graphtecamerica.com/cp-softwares

-

Yes I see that, Autorun doesn't work when clicked upon. I don't see the readme either.

-

13 minutes ago, MZ SKEETER said:The magnet parts are for the industrial market who use the metric (preferred) system. Thank you for checking the dimensions!

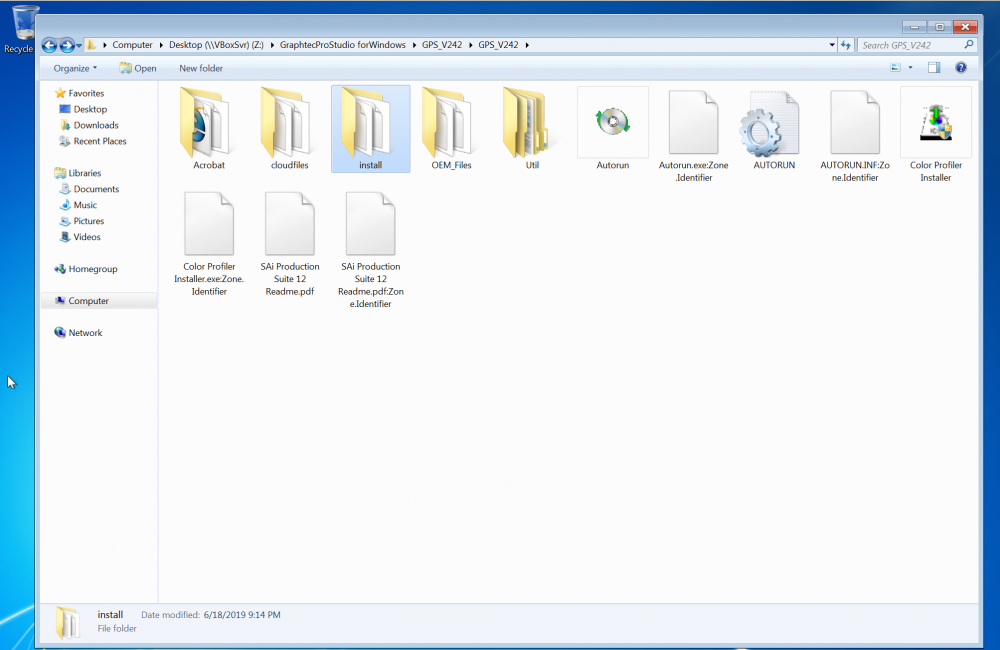

I can't seem to be able to install Graphtec Pro Studio on Windows for some reason:

-

-

1 hour ago, MZ SKEETER said:They are not designed anything alike. Graphtec Prostudio is an fs file. not a gs file. Graphtec Pro Studio is from Flexi SAI. The same as my Flexidesigner 10.5 My Flexidesigner is Flexisign Pro with out the cutter drivers. I don't have time right now. am leaving for Post office. But I will fire that computer up after I get back. Or someone else with it can beat me to it.

Thank you; much appreciated!

-

I prefer to use a Virtual machine instead of bootcamp, but yes, I could definitely go the Windows route. I have a feeling that graphtec pro studio would import the DXFs incorrectly just like the mac version does.

-

10 minutes ago, MZ SKEETER said:Is it supposed to be this? This is on Flexidesigner 10.5 several years old. This is what I use for my design software. I have the Graphtec Pro Studio loaded on another computer. but that computer is loaded up for my FC8000 and put away. But I stay with what I have been using for years. I still only cut with the FC7000 until my son decides to buy it.

Yes, that image looks correct.

-

Ok great.

By the way, here is one of the dxf files that I need to cut frequently. Can you see if it imports properly?

-

9 minutes ago, MZ SKEETER said:Out of the box is a holder for the CBO9U blade. regular vinyl cutting. The FC8000 that I got, they had been cutting reflective vinyl. So it had the red cap blade holder in it for that blade. You will have to go to the Graphtec site or Ebay and get a holder for that blade by the blade number. The last owner of the FC8000 even installed 2 extra pinch rollers on it. It has 4 now. It is a 30" cutter. They come standard with 2 pinch rollers.

Will I need more than the standard 2 pinch rollers? They're about $250 a piece extra.

-

Also ordered two cleancut blades that were similar to the ones I have been trying with the titan 2. Too bad they aren't compatible; oh well.

@MZ SKEETER This is what I bought: http://cleancutblade.mybigcommerce.com/graphtec-cb15u-60-metal/

Does a standard FC8600 come with the right type of blade holder out of the box so I won't need to buy anything else to use that blade?

-

Just ordered a new FC8600-60; let's hope it's a beast!

-

4 minutes ago, MZ SKEETER said:You stated you are doing squares, rectangles, circles, off circles, You can do that in FREE inkscape and export as an .eps. What are we missing? Very, very detailed designs can be done in .eps. I do them all the time.

Fusion 360 is used to create the shapes on demand as orders come in, all we do is change two parameters and since Fusion 360 is parametric, it automatically changes the sketch dimensions on the fly (much faster workflow). For circular shapes, we have one parameter.

-

20 minutes ago, darcshadow said:If possible you'd be doing yourself a favor to get away from the dxf file format. Several cutting programs can open them, but they never seem to work as well as an eps. dxf files seem to have disconnected nodes quite often, so while it looks good on the screen, the cutter is lifting and dropping the blade unnecessarily and you can end up with cuts that have a lot of points still connected.

That's not possible since Fusion 360 is used for the cad modeling and dxf exporting is the preferred and best format for exporting a sketch profile.

-

I tried out the Graphtec Studio software for mac last night, and it imports the DXF files incorrectly. Sure Cuts a Lot imports them correctly, but I don't know if the Camm-1 GS-24 or FC8600 is supported?

-

11 minutes ago, MZ SKEETER said:correct, a lot less force than the Titan 2 you were using. The Graphtec requires a plug in for illustrator also. Very few mac cutting softwares out there. We usually try to convince people to just get a cheap Windows computer. I still cut on a 2006 Toshiba laptop with Windows XP on my Graphtecs. No problems. You don't need a fancy computer to run a vinyl cutter.

Graphtec appears to have software for the mac: https://www.graphtecamerica.com/cp-software-studio-mac

On the titan 2 force, when I tried higher force settings, that actually made the cut quality worse for some reason.

-

7 minutes ago, MZ SKEETER said:The force is much less at 350g FC goes up to 600g. You have to compare the specs. But that is your choice.

Less force means I need more passes, correct?

Doesn't look like the gs-24 plays nicely with macOS due to it requiring an Adobe Illustrator plugin.

-

12 minutes ago, haumana said:I'd be located in the middle of the Pacific (Hawaii).

Oh wow, a bit far!

The Roland Camm-1 GS-24 seems like it may work as well for my needs?

-

1 hour ago, haumana said:I'd run it through my laser, but i highly doubt it's worth you sending it to me. maybe someone who is closer, with a laser, will chime in.

Are you located far away from the east coast?

Help!! Magnet cutting, machine hard to calibrate

in TITAN 2 Series Vinyl Cutter Discussions

Posted

Yes, SCALP and, the built in one with mac, everything else is working as expected. Here's my settings:

I have the step size on the machine correctly set to 2032 to match.