kmorenor

-

Content Count

22 -

Joined

-

Last visited

Posts posted by kmorenor

-

-

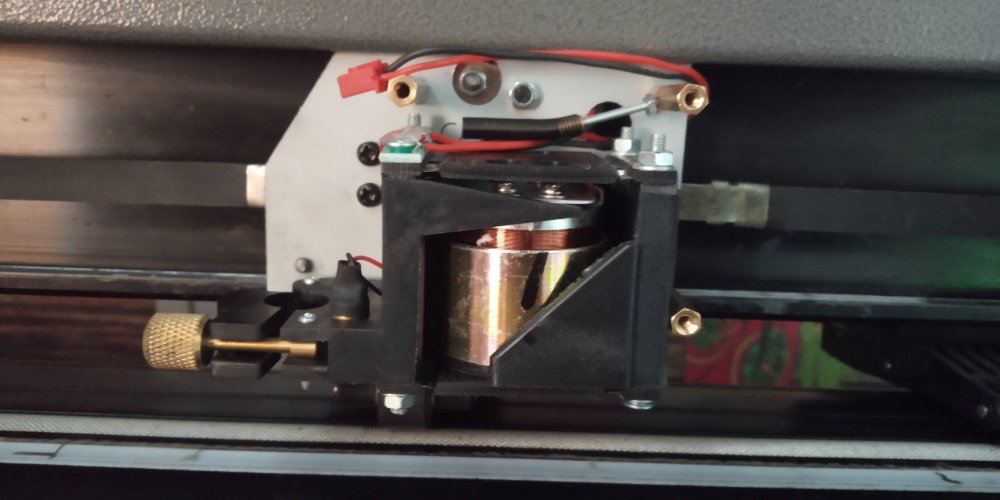

44 minutes ago, Dakotagrafx said:sure looks like a carriage for a sc plotter - that is made my liyu and not refine that made your plotter - are you sure it is for you model and version of plotter?

https://www.uscutter.com/Replacement-Carriage-for-SC-Series-Vinyl-cutters?utm_source=google&utm_medium=cpc&utm_campaign=PLA&gclid=Cj0KCQjwvvj5BRDkARIsAGD9vlK7xQQ8LfNj-lGDAwOwW0QUCA1c6skAs8UZakgpkSqUWk1e6CNwiXEaAv_0EALw_wcBWell it's exactly the same, just that the new came with a laser. I compared them and they're the same size, they fit in the rail. And I asked for a MH 871 MK and that's what arrived.

-

2 hours ago, MZ SKEETER said:Take the carriage head cover off, as he mentioned. See what is keeping the arm from coming down. Show some pictures of the inside of the carriage head.

Hello, It doesn't seem to be something keeping the holder to come down. As I said before, the problem is the pressure that it makes. Its too low. No matter thah it's set on maximum.

-

2 hours ago, darcshadow said:In that last photo, is the cutter turned on?

Ok, I think I missed that the problem started, you replaced the carriage head and it didn't solve the problem? So I think we're looking in the wrong location. The problem just about has to be the rails the head is riding on.

Sorry, yes the cutter is on.

-

2 hours ago, darcshadow said:In that last photo, is the cutter turned on?

Ok, I think I missed that the problem started, you replaced the carriage head and it didn't solve the problem? So I think we're looking in the wrong location. The problem just about has to be the rails the head is riding on.

Yes, the carriage is new, hoping that the old one was defective. What can I look for on the rails? They seem to be well leveled, well lubricated, I clean them often.

-

Hello friends, thank you all for your replies, I'm still working on the cutter. Send you a video so you can see what happens. Bye.

-

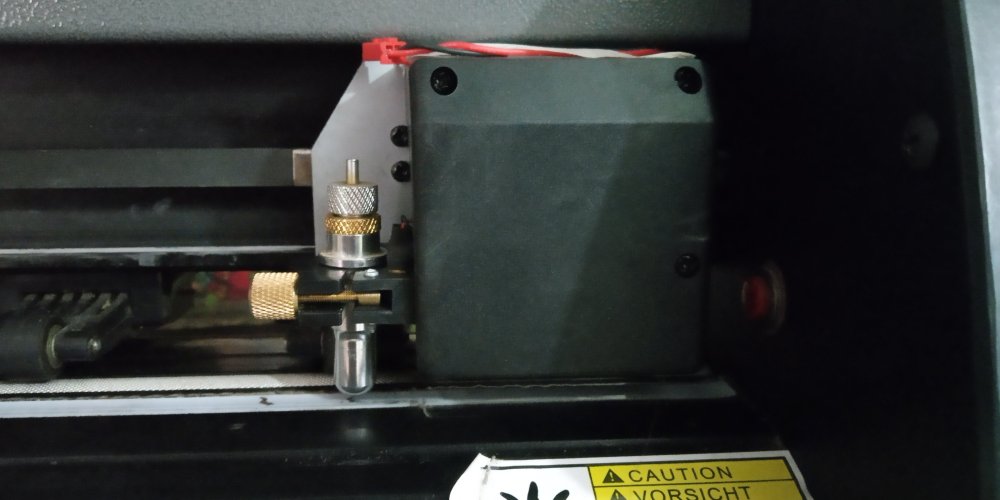

16 minutes ago, MZ SKEETER said:Is that spring on top hooked up like it should be? Darcshadow's spring doesn't look like that.

Hello, that's the way it came. Just bought it.

-

18 hours ago, darcshadow said:Another question, with the cutter turned off, if you put a bit of weight/pressure on the arm can you get the blade holder to touch the cutting strip?

the 5 years you've used it, have you always had to have the blade sticking out so far, or is this a new development?

Hello, yeah, if I move it down, it can go lower.

19 hours ago, darcshadow said:Thanks, yeah, missed that one.

So then the question is, did something happen/change before it stopped working?

Hello, no, I just came to work, put a sheet of vinyl for a car decal, and It just wouldn't cut it. Just left the mark, but didn't go through the material. I changed the blade, but didn't work. And so and so. Could be a board problem? By the way, here's the new carriage.

-

18 hours ago, darcshadow said:Another question, with the cutter turned off, if you put a bit of weight/pressure on the arm can you get the blade holder to touch the cutting strip?

the 5 years you've used it, have you always had to have the blade sticking out so far, or is this a new development?

Hello, no, before the problem, the blade barely showed. And the cutpress was always set on 90~120 aprox. Just someday It wouldn't cut hard enough.

-

19 hours ago, darcshadow said:Is the carriage head seated on the rail correctly? Clearly there's a position problem as the blade holder should be touching the cutting strip when the cutter is turned off.

I'm not near my cutter right now but when i get a chance I'll look at mine closer and see if I can see anything that you could adjust or account for the extra height you're seeing.

Again though, has this cutter ever worked for you? Or is this a new problem?

Hello, the cutter worked for me fine until that problem. At least 3 years, no problem. This is last year.

-

-

-

-

6 hours ago, darcshadow said:He has the holder in correct for a MH.

Is the holder straight? In some of the photos it looks like it might be at a light angle. I had a problem with mine where holes in the arm were not lined up and the blade holder would sit an a bit of an angle. I took a file to the arm and filed the hole till the top and bottom lined up. I then had to put a few layers of tape around the holder so that it would fit tight and not move around but it worked out well for me.

The cutting strip looks pretty tore up as well and could be contributing to the problem.

Has the cutter ever worked for you?

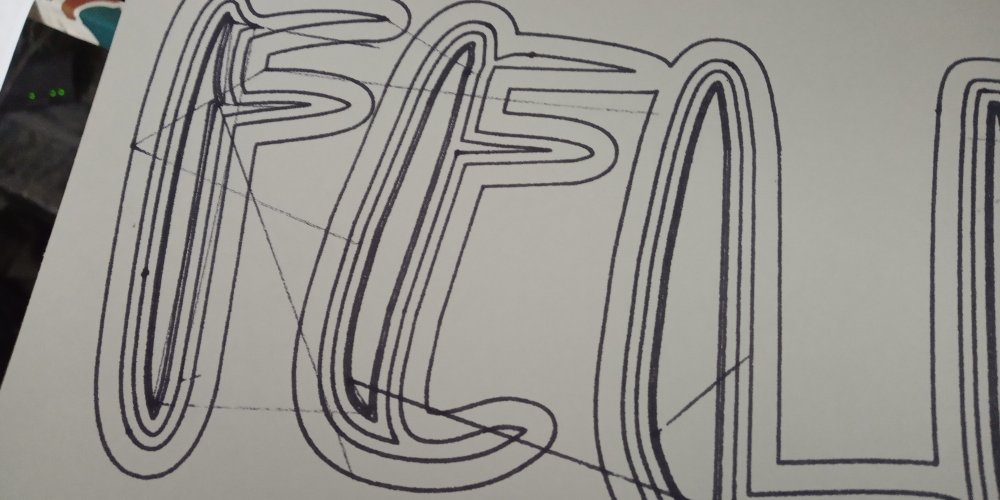

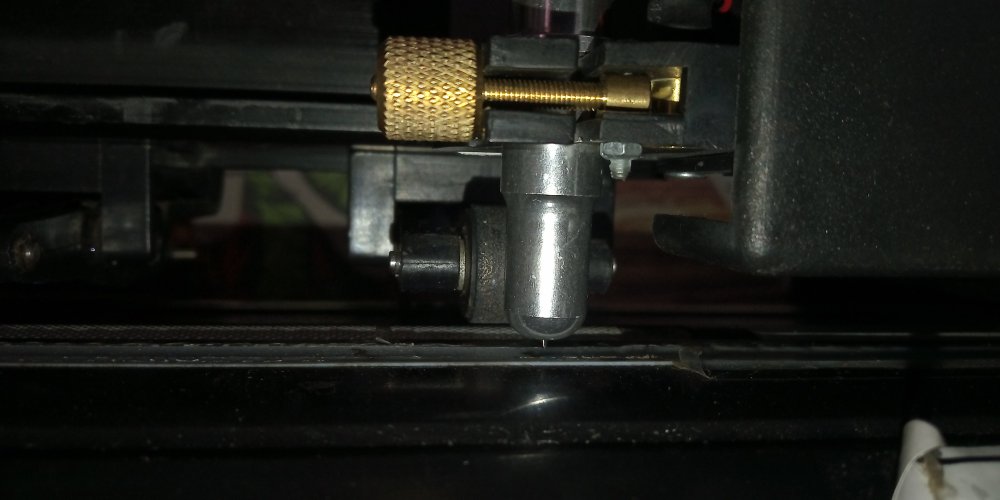

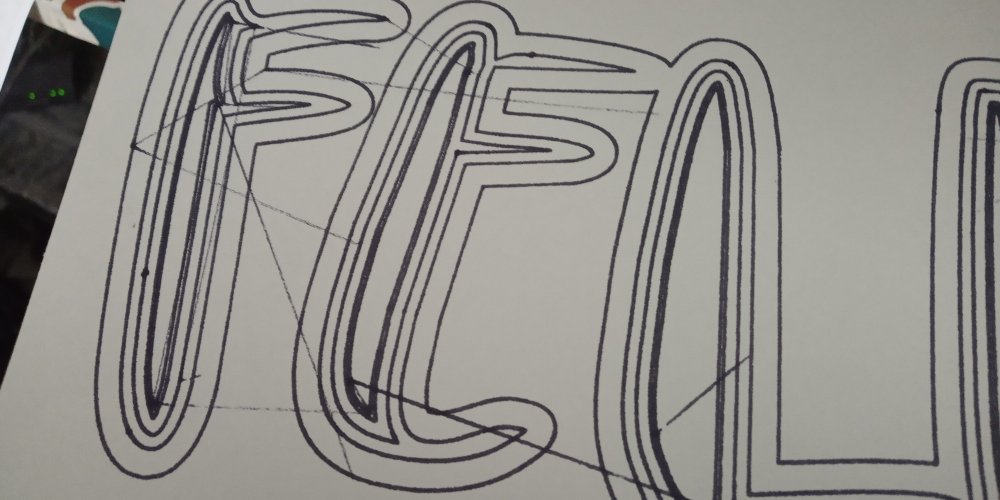

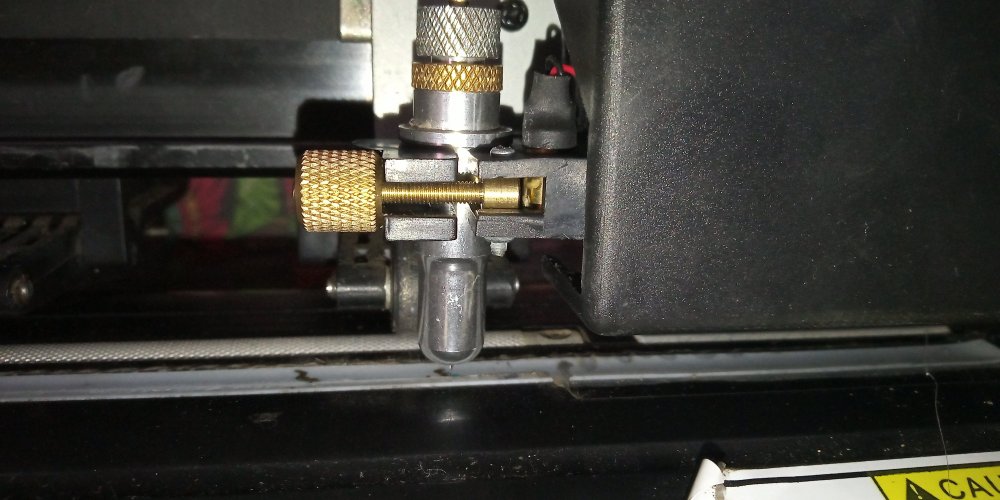

Hello, the cutter has been working OK, just some random day, it wouldn't cut. Like it's not strong enough to go trough the material. The blade holder is straight. There may be some tearing in the cutting strip, but the problem is about the cutting press. In the drawing it looks that the blade/pen touches the material where it is not supposed to cut. If I lift the blade a little bit, it doesn't even touch the cutting strip.

-

-

5 minutes ago, MZ SKEETER said:Maybe some of these people who own the MH cutter can come a long and help. A good working cutter, you shouldn't have to do that. You keep the blade as short as possible.

Whit a short blade it cuts nothing.

-

2 minutes ago, MZ SKEETER said:From what I am seeing you have way too much blade exposed out of the blade holder. HTV and regular sign vinyl normally have the same cutting settings. Also check for scratches and gouges in your cutting strip. They will cause problems. You should just barely see the blade tip out of the blade holder.

This is correct way to set your blade depth.

To start with, you should set your blade depth correctly, by taking the blade holder out of the machine, and in your hand, firmly cut across a piece of scrap vinyl, you will be cutting. You should only be cutting the vinyl and barely a mark on wax paper backing, Adjust blade to get there, Then put the blade holder back in machine, and use the force of the machine to get there, same results, only cutting the vinyl and barely a mark in wax paper backing. You should just barely see and feel your blade tip out of the blade holder.

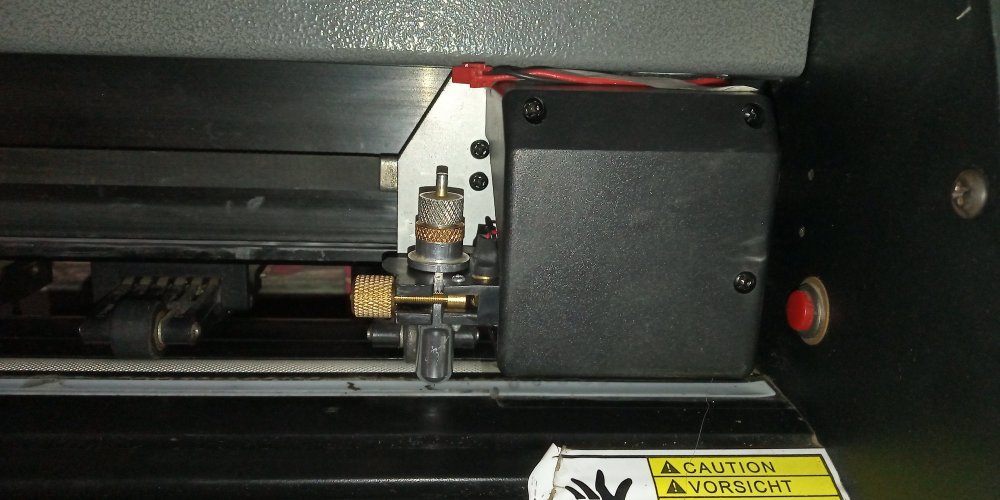

Yeah I have a lot of blade showing, because, if I cut it down, it won't reach the vinyl. So I have to set it as long as possible. My problem is that it doesn't go down strong enough to cut whatever is on the mat. The press is set at maximum, 600g, and with that much blade out, it would go through any material, but it doesn't. So, not enough strength. And it's a new carriage.

-

9 minutes ago, MZ SKEETER said:Isn't the ring of the blade holder supposed to be inside the clamp? Isn't there a groove inside that the ring fits in? .

It could be part of the problem man, if I put it down, it hits the bottom and would be messy. Is there any way of diagnosing the board?

-

2 hours ago, darcshadow said:Could this possibly be the rare case where someone has too little blade exposed?

Noo man, come on. I've been working a lot with this cutter, just some day it wouldn't cut deep enough.

-

2 hours ago, MZ SKEETER said:Show pictures of the the carriage and blade holder. Are you sure you have the blade holder inside the clamp? Is the carriage head wheels firmly down in the rail? Is the blade holder going up and down? How did you set your blade depth? Is this a new cutter? What do you mean, just leaves the mark? Have you checked that you haven't broken the blade tip off?

Hey man, thank you for answering.

Are you sure you have the blade holder inside the clamp? Yes it is.

Is the carriage head wheels firmly down in the rail? Yes, I double checked. As a matter of fact I just replaced the carriage, but the problem persists.

Is the blade holder going up and down? Yes, i see it going up and down. But when it goes down, i notice it lacks strength.

How did you set your blade depth? Manually. Before it malfunctioned, i use to have less than 1 mm out of blade. Now I need up to 3 mm to cut just heat transfer vinyl, that's the only material it cuts.

Is this a new cutter? No, it's been working for 5 years, but other than that, it's perfect.

What do you mean, just leaves the mark? It means the blade leaves the trail where it passes, but doesn't go trough the vinyl.

Have you checked that you haven't broken the blade tip off? I have tried with several brand new blades.

It started randomly, just one day I needed to cut htv, but it wouldn't go through with my normal settings, you know, I used to work with medium speed and about 120-90 g in force. Now, I have to set it at maximum.

Can you see the marks it leaves in the sketch. And if I pull it up just a little bit, it doesn't touch the paper.

Will send videos.

Thanks. -

1 hour ago, Dakotagrafx said:usually when we hear this complaint it is someone cutting the wrong side of htv - looking forward to more info

Hey man, thanks for answering, but, no, not the case. In fact, I have no trouble with heat transfer vinyl, because it´s softer than vinyl. I've been working with that cutter for over 5 years. It's in perfect condition. Just started to lose strength when it comes to harder materials. That's It. It would go over the design and hit the vinyl with the blade, but does not go deeper, and just leaves the trail where the blade passes. I have tried with different speeds and force, but nothing. When I'm sketching, the pen marks the way of the carriage. If I put it a bit up, it doesn't touch the paper, if I put it a little bit down, it cuts/writes all along the way of the carriage. Today, I have to let 2 or 3mm of blade to cut htv, and all of the strength, which as you know, 600g is a lot for a well functional cutting machine. In the picture you can see that I have more than enough blade out, but it barely cuts. By the way, the blade is brand new.

-

Hi fellas, I've been having some weird trouble with mi USCUTTER MH 871, it doesn't cut vinyl, just leaves the mark, but doesn't penetrate. Even with the force on maximum. I just changed the carriage in hope that the old one was the cause, but the problem persists. Someone can help? Thanks!

Trouble with my us cutter mh 871

in MH Series Vinyl Cutters

Posted

Hello, both the old ant the new one fit in the rail the same way, I checked, both sides of the rail and the screws are real tight, wouldn't know what could cause the carriage to be higher than it should.Does any of you help with a manual of how to dismantle it?