-

Content Count

2,673 -

Joined

-

Last visited

-

Days Won

60

Posts posted by skarekrow

-

-

I've had excellent results with Orafol 751 and 951 on Marine installations.

They're both Cast Vinyls with the exact same adhesive.

The 951 is rated @ 8-10 years and the 751 @ 7 - 8 years, depending upon color and sheen.

-

Yes, Dakota, that is how the 'Drop Shadow' function in Vm works.

As far as not having the 2 layers over top of one another;

Ungroup the 2 layers (grouped by Default when Created with the Drop Shadow Module)

And Punch them out. (Not sure if the Cut Version has all these Features.

-

3

3

-

-

I also had problems with it crashing with large files on my laptop but

it's been smooth sailing on this i7 Desktop with 16 gigs of ram.

-

1

1

-

-

On 4/19/2019 at 11:18 AM, ShaneGreen said:Quote >... the native vdoc aren't viewable as thumbnails in other programs. <

Thumbnails of your vDocs can be previewed with Adobe Bridge.

-

-

-

9 hours ago, MZ SKEETER said:. What does this mean? " I’ve purchased two holiday sigh usb’s From uscutter."

The Products are apparently shipped to the Buyer on (physical) USB Flash Drives.

-

How about The History Channel ?

-

3

3

-

-

QUOTE from OP > ... and even the entire cutter swapped out for a new one and I am have the same issue!!! <

This would indicate that the problem may likely be with the Computer itself.

Windows 10 has presented plotter issues for other users too... maybe install your VinylMaster on an

older version of Windows and/or try (free) Signblazer Plotter Program to completely eliminate those variables .

Which version of Vinylmaster are you using?

-

The Ioline Cutters are listed in my VinylMaster Pro Setup Wizard.

-

2

2

-

-

-

2 hours ago, autometrik said:QUOTE > practice, practice, practice like hell, over and over until they get it right...<

Practice at 'Hand-Trimming' vinyl is fairly fruitless if your Goal is to get a Cutter.

Your Practice time would be better spent working with Imaging Software and Vector Graphics, IMO.

There are a few Free Programs such as Inkscape and Sign Blazer that may Better advance your Knowledge Base.

2cents.

-

3

3

-

-

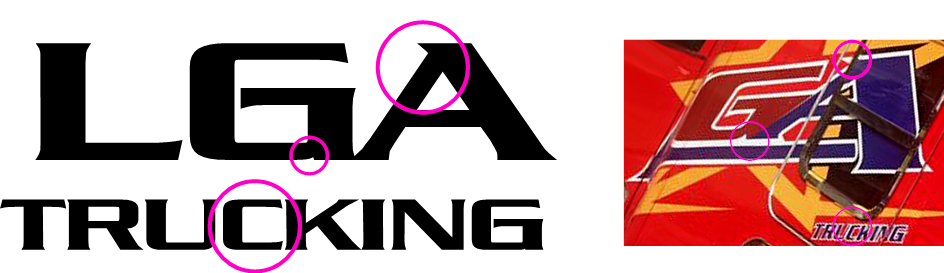

Not sure why there's no other answers...

Looks like Franklin Gothic (maybe Bold) ?

Might even have a little extra slant added...

-

Here's a few Vectors of the Polish 'Falcon' (Eagle);

Google is your Friend....

-

1

1

-

-

Thanks folks... and Happy 2 Oblige, DNA.

-

Thanks, Goose...

-

-

Here's a quick, 2 color redraw... Perhaps it can Help you.

It's far from perfect but the Price is Right !

edit: "Norwich Family Dental Associates" that appears below your posted image

looks to be either Times New Roman (bold italic) or the similar, Adobe Caslon ?

-

4

4

-

-

Yup... Figuring out what works best for one's Workflow & Budget is a big deal for a shop.

What may work perfect for one may be disaster for another.

I print just a few Positives a week to burn Screens with and the

OEM Epson pigment inks Print fine, solid Transparencies for the Halftone work,

without breaking the Bank.

Also have no issues with Chip Reset Workarounds & Schemes.

-

1

1

-

-

Agreed... Wise to stick with the Quality Products and Workmanship.

The Graphics Industry has been swept the way of so many other Products and Services these days.

Our World is flush with Walmart Mentality and Confusion of Low Price / Good Value.

-

1

1

-

-

There must be a large number of shops using poor quality inks and substrate then.

I see a lot of Printed Vinyl that's faded and/or cracked.

(or perhaps the Custy's aren't taking proper care of it?)

-

I'm with you there, Dakota. I stick to OEM inks in my Epsons as well.

-

Sorry, admittedly, I just scanned the Headings. I have to agree with you though Bevins...

from what I know about desktop inkjet inks and PU and PolyVinyls,

doesn't seem likely that the inks would adhere well or for very long.

Seems like they haven't even really perfected the ecosolvent vinyl printing from the

amount of it I see fading and peeling.

-

It does exist... Here are a few ads for "Inkjet Printable HTV";

https://www.brilliantvinyl.com/Inkjet-Printable-HTV-Transfers/

https://www.heattransferwarehouse.com/category/printable-heat-transfer-vinyl

https://www.amazon.com/Printable-Transfer-Printer-Fabrics-T-shirts/dp/B07BS7556S

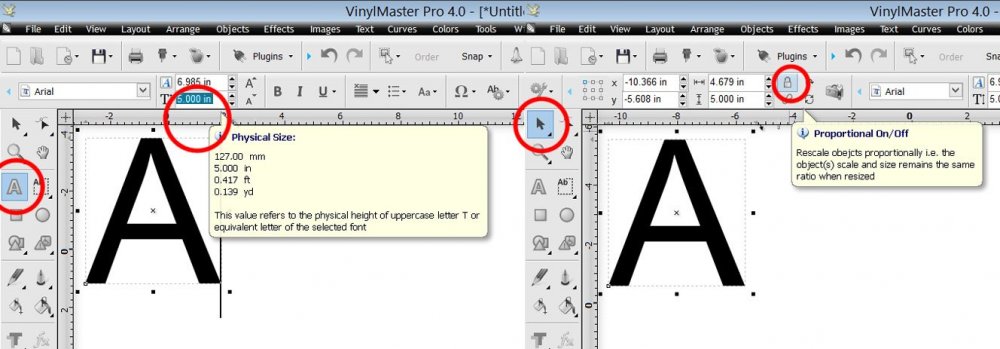

Can't Vectorize an image in Vinylmaster Cut

in VinylMaster CUT, LTR, PRO & DSR

Posted

Re-Save your Original image in a Bitmap Program like Photoshop or Gimp as a .jpg with a

slightly larger background so that the Black in your Example Image

does not touch the outside edges of the Background.

Alternately, you could remove the white background in a bitmap Program and save as a .png with a

TRANSPARENT background and Trace in VinylMaster..

Then, Vector Trace.