The Flaming Eyeball

-

Content Count

33 -

Joined

-

Last visited

Posts posted by The Flaming Eyeball

-

-

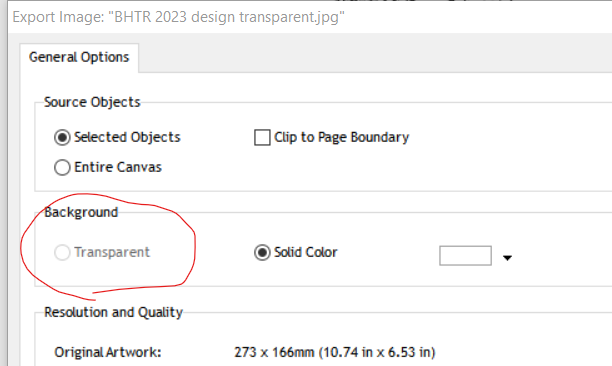

At what level does Vinyl master unlock the transparent background? I have 5.0 LTR.....frustrating to keep upgrading for a single tool enhancement. It seems it used to work previously as well....not sure how I did it though, didn't use any other software.

-

Has anyone converted their SC2 for use on a table or desk? I'm doing some rearranging, and was trying to figure out if there was a way to use the roller system for holding rolls of vinyl, in a desk or table configuration so I can put the rolling stand away. I don't need it out in the middle of the office anymore.

-

15 hours ago, MZ SKEETER said:Have you used the cable for years also? Try a new cable. Always best to put a value cutter on a serial cable or a Tripp-lite Keyspan adapter/ your null modem cable ,for the best communication. It's been stated 100's of times on here. Tripp-lite is the brand name. That cutter has a cheap Chinese chip set in it, NOT True USB like higher end cutters.

So this answers one question. Any idea about the others?

-

1 minute ago, slice&dice said:What software?

Vinyl Master LTR 4.3.

-

I have an SC2 that I've been using successfully for a couple years now. But a few issues have started coming up lately.

1. I have the box checked to 'Advance After Plot', but the cutter no longer does this. It used to advance the perfect amount to use the cutting slot, now I have to do it manually. Any guesses?

2. If I don't use the cutter for a time and turn it off, when I turn it back on, I can hear the sound for a device connecting, but the software will not send to the SC2 when I click 'Cut Now'. Just sits there. I usually have to restart the computer, not just the software to get it to cut.

3. Are there any driver updates for the SC2?

-

Thanks. I do have a carrier sheet for cutting small pieces of vinyl, so I'm familiar with how that works. I'll keep looking.

-

I searched the threads, but didn't see anything on this. I have an SC2 and I want to make custom sized boxes for gifts. first, can I do this on my SC2. Second are there templates or patterns available somewhere? Thanks for the assist.

-

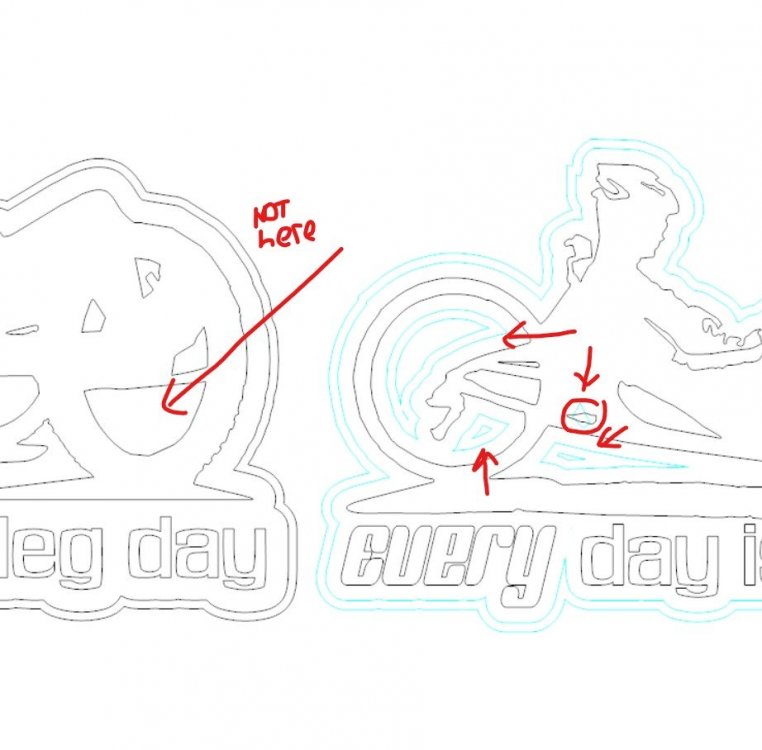

8 hours ago, slice&dice said:2. Node Edit and remove the extra stuff you don't want. Do you know how to do that?

I do know how to node edit, but when using the outline effect vs. the outline module you can't edit the nodes from what I can tell.

-

OK, all thanks for the advice. Sleep helped, as usual it came to me as I was just drifting off......what if I punched it out....? zzzzzzzzzz.........

So this morning tried again. Used the Outline module, which makes it a separate graphic, so to speak. Did that twice, and punched it out from the second one, which was a bit smaller. Viola! I now have an outline that I can resize and no extra stuff in the middle!

As for the blades dulling, that was a theoretical statement to avoid extra cutting, this is still my first blade, and I've cut a lot of stuff with it over the past year+ and I don't see any signs of it stopping yet.I now have a clean outline that I can change colors on and have it separate from the graphic so it will all be one layer, with no weird cutting lines in the middle

-

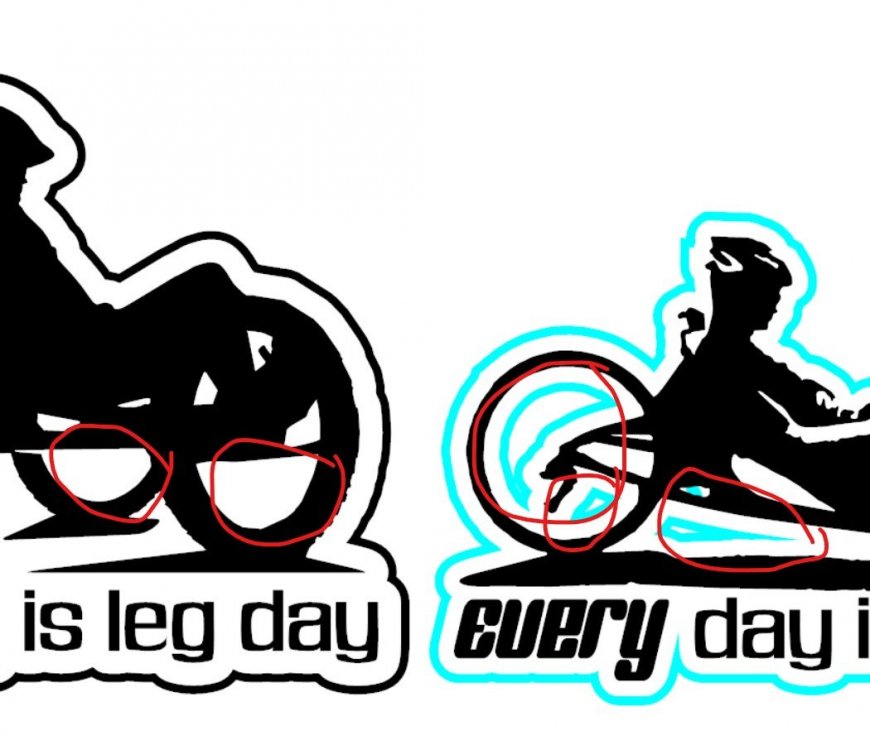

I had a decal I made previously. I added an outline and was able to cut it just like I wanted: an outline.

Now, I'm trying to create a new decal and do the same effect....but now I keep getting the outline in all the holes (and yes, I've tried both with keeping the holes and without) And I get these weird anomalies in the small holes of the graphic.

So these are the two graphics. The one on the left is the one I've done previously, the right is the current project. Red circles are the weird outlines that show better in the wire frame in the next pic. Left pic is how I want it to cut, I suppose I could cut it like the right and weed it all out, but why waste even the smallest amount of cutting with my blade, and shorten the life unnecessarily.

I'm using Vinyl Master LTR, and was able to do this just fine previously, but different day, no joy. Any guesses? TIA.

-

Definitely long lead times, and this is not a forum I frequent often....Buuuuutttt, the guy STILL has not actually decided to purchase said reflective vinyl, so I have yet to play with it. Might invest in a laser cutter for that anyway.

-

I know this is an old thread, but i did the same thing. Bought the starter pack with all the cheaper stuff. I used to have an ancient Hix press, but gave it away after not using it for several years, back when I was doing airbrushing. Anyway, noticed my Siser Easy-weed Stretch wasn't sticking to my Bell + Canvas shirts after the first press, started to come up around the edges....ARGH!

Got out the laser dog toy (well, that's what my kids use it for) and found out the temp setting at 305, was really only 287! What! So I had to go all the way up to 328 before the platen reached 305. Repressed and now the shirt is in the wash doing it's first test.I'm so glad I did some test shirts before sending to a customer. Nice to know Stretch can go a bit higher and still be OK.

-

1

1

-

-

OH!!! that tiny little blue arrow......wow.

-

2

2

-

-

Further research. I see on the US Cutter "Vinyl Cutter Buying Guide" that the SC2 is not recommended for cutting reflective material anyway. Is "not recommended" and "not able" to the same thing in this case? Can the SC2 handle reflective?

-

Hey all, back again. What about pricing for reflective? Looking at using ORALITE 5500 Engineer Grade Reflective Film, unless there is something cheaper.

-

removed due to bad math....lol

-

Not really. I went there and only have the few fonts from Cut.

-

I upgraded my VM from Cut to LTR....problem is now I can't find all the 5200 fonts it says it comes with. Any ideas? I did download and install the 'extra' pack as well, but still no joy. I know I don't necessarily want to install all 5200 fonts on my computer for speed issues, but where do I find the others now that I paid for them?

-

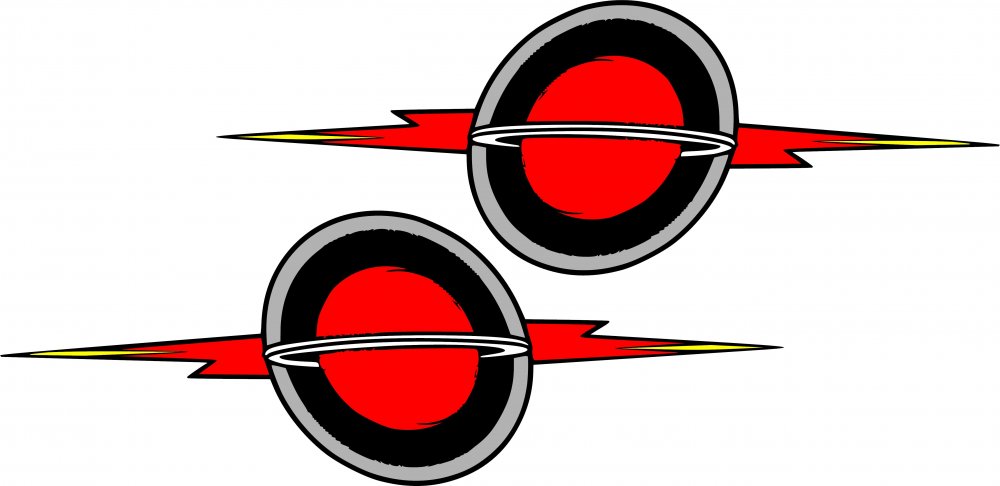

I'm looking at making some layered graphics with several colors. One color would be the big base for all others. None of them will overlap except to the base, so only 2 layers even with the multiple colors, see attached to make sense of what I'm talking about. These will be somewhere in the neighborhood of 36 inches long by about 13.5 or so.

Question concerns shipping. I have to roll them up to send them. Do I roll vinyl in or out for best results? I'm thinking outside as that is how the vinyl comes in the first place. My concern is for the vinyl separating during shipping if left in a warm mail van too long....using Oracal 651, and now using paper transfer tape. ;-)

-

Thanks Skeeter. I figured you'd have an answer. So much for following the manufacturer's guidelines. I'll make the suggested changes and see what happens. I do think I may have the blade depth too deep, as you say I can clearly see where the decal was cut after it has been removed from the paper.

[Sometime later] OK, checked blade out of cutter. That thing is BARELY out of the end of the holder. But I could still see the cut on the backing paper. So I adjusted it some more. I didn't think it would cut. Sure enough it cut the vinyl and barely made a mark on the backing paper. Still have to test out a machine cut, but wow. I suspect I will have to make more adjustments now with offset and such. I do try and cut at lower speeds to keep things clean (and I don't really have a lot of volume to demand speed).

Now to order some of that new transfer paper....

-

1

1

-

-

So what IS the best transfer tape for 651? I used the MT80P and it just doesn't seem to lift detailed vinyl off the backing paper. My customer destroyed his vinyl trying to apply using this transfer tape. The HT55 I have does not seem tacking enough either.

I'm producing a logo cut out (customer provided) that is fairly detailed and is kind of a pain to weed I might add. Maybe it's too detailed for vinyl cut out application? I tried to get him to change the font, but that was a no go. Some of the tiny little pieces just don't want to lift off the backing paper. Should I even continue trying this?

-

As it turns out he loved them anyway. But it bothered me. What transfer tape is best? I'm using the MT80P clear type. I have some Oratape HT55, but it is not nearly as sticky, and it makes it difficult for the vinyl to come off the backing.

-

So I had my stuff saved on an external drive, which unfortunately died. Since my business is more on the hobby side I wasn't TOO worried about it until someone asked me for repeats....I'm glad I thought of the spooler, because it saved me a TON of work. Now if I could just get the files BACK.....oh well.

-

So it would appear I have the same issue as a lot of others. I was about to deep discount some 'stickers' of layered vinyl. I tried my best to get all the bubbles out from the top layer with no avail. These will be going on a vehicle, which will spend some time outside. Will the heat of the sun get rid of these tiny little annoying things? These are not a local to me install, mailed and customer installed. Both are Oracal 651.

Small decal guy, pricing first BIG job

in Business Practices, Sales and Pricing, etc.

Posted

I've had my SC2 for 3 or 4 years now. I've been making decals for a specific group (per Mz. Skeeter, I found my niche in the recumbent cycling world) I've done a couple big decal sets for a couple of trailers, but in all cases, these were customer installed. I only cut and mailed or delivered the decals. I've been happily making them and have had spurts of orders then not much, but this was a side/hobby job to begin with, not at all putting food on the table, just some thing to play with as I near retirement. I also use it in my powder coating business to make stencils.

I just got a call (from a previous $20 customer) for an order of door numbers for a warehouse. A lot of doors. In talking to the customer for the final bid, he asked if I could do double that work, and in two colors. Then he asked if I was sitting down (lol) and asked if I could do a warehouse with about 500 doors. We're talking 8 inch Helvetica numbers, so lots of vinyl for sure.

I'm using the X plus Y divided by 2, plus 20% for my pricing (24 inches X 24 inches divided by 2, plus 20% = $28.80, for example) customer installed. Then he asked about how much I'd charge to install them.....

These are warehouse doors where semis back up to them, so installation would be with a step ladder, then a quick clean of the area, apply the numbers and move on...I'm being conservative with a 10-12 minute per door, including all the moving of the equipment, I think. We're talking a warehouse that is nearly 3/4 of a mile long, as well.

First off, am I in the ballpark for my pricing to begin with?

Where would I even start to price labor for installation, especially in June/July in VA, and going up and down a ladder all the time to do it? All my previous work has been with the customer performing the installation.

I could also give the 'screw you' pricing, but if they accept that would be good I suppose. I do still have a full-time job that would get in the way...

How do you price this kind of work when you are asked to install the vinyl on site (travel)?