How sharp and precise should corners be? Still having issues ce600

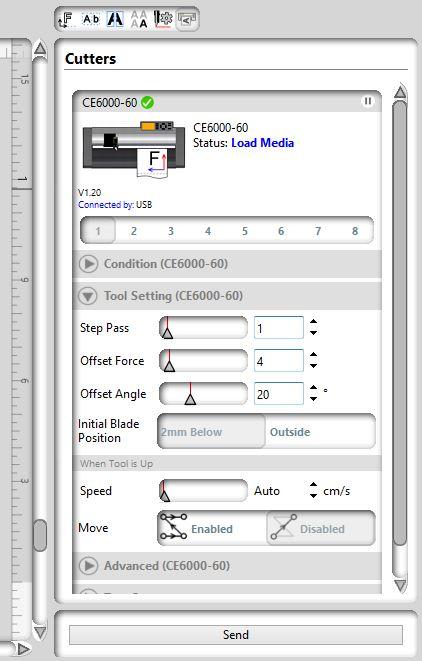

I still seem to be having issues with the ce6000-60. I have tried every setting I can think of and the only way I can get clean and sharp corners and O’s with out “hang nails” is using tangential mode 2 and offset -2. With these settings my test triangles are sharp . This setting is consistent with both the Graphtec stock blade and a 45 & 60 Clean Cut Blade.

Everything I have read on this forum and others say the offset should be 0. When my settings are at 0 and everything is defaulted my cuts look bad . Little nubs on the corners and the issue with circles

It’s not the cutter it’s not the computer or software so I must be doing something wrong and I am not sure what. I have searched and found a others having the same issues with ce6000’s & 5000s in a few different forums but no one ever posts a resolution. I have readjusted the blades many many times. I am confident it is set correctly. I have pretty much only used 651 but have tried 4 different rolls. I have tried just about every setting there is (I wasted a lot of vinyl) I am not sure what else to do

Am I expecting too much from the cutter? Do you guys have some pic of text close up that you can post so I can compare.

I am very frustrated at this point. I will give Graphtec a call Monday.