-

Content Count

287 -

Joined

-

Last visited

-

Days Won

6

Posts posted by kainth.c.s

-

-

Hi everyone

Has anyone got any idea wherein I can get the teflon strip for this cutter which is about 2 mm thick and less than 8 mm in width?

The strip need not be glued or fixed using double sided tape but inserted into the channel made next to the ruler.

The strips I got from the company are 1.5 mm but the one on the cutter is 2 mm. Thus the vinyl is not cutting properly.

Any help would be greatly appreciated

-

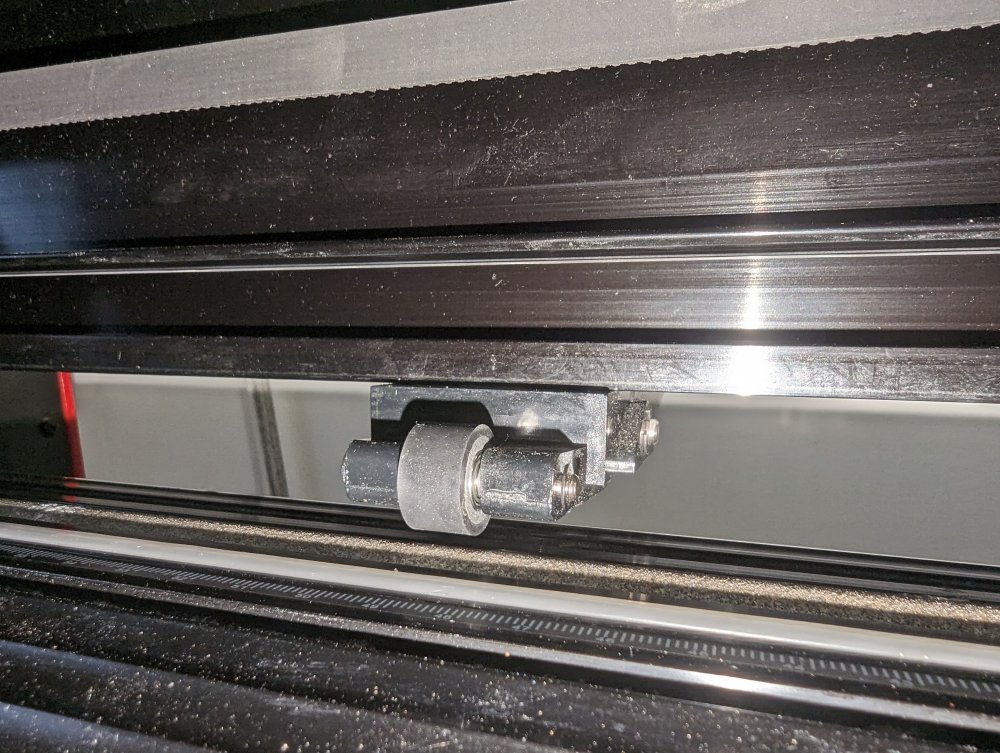

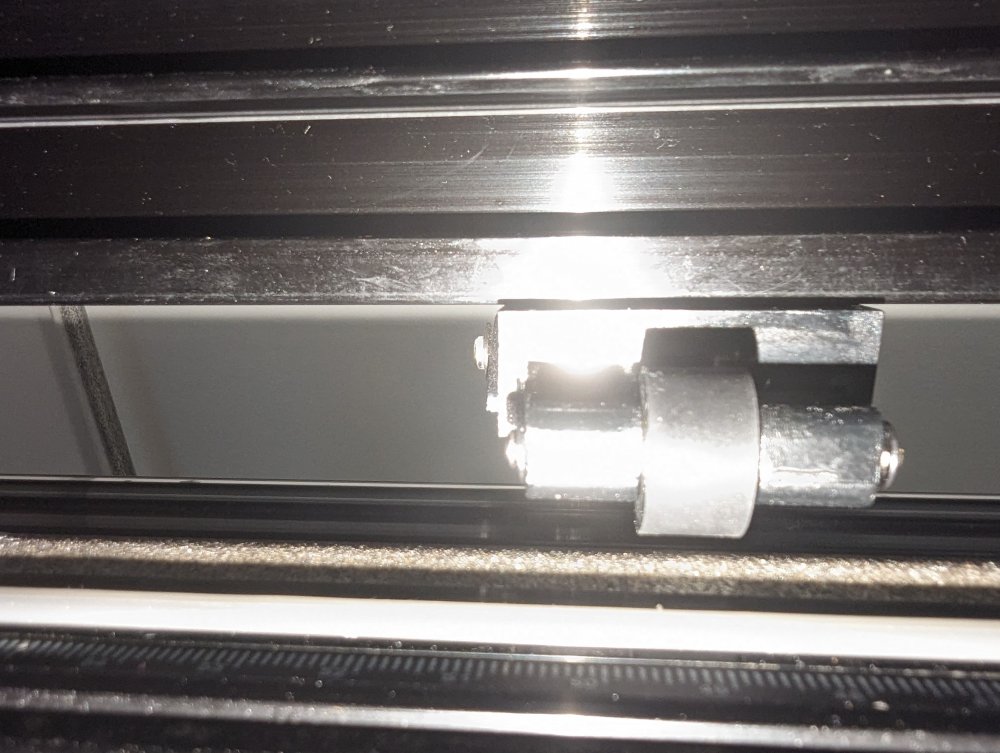

I just replaced pinch roller wheels on my Graphtec ce 5000, after 15 years, one was dry rotted the, other one had a flat spot on it. So, yeah they wear out.

15 years, looks like you looked after the machine quite well.

Yes, they do wear out but you can prolong their life by regularly cleaning them, not keeping them pressed for long time and some other easy tips which can be done in the spare time

-

OIC.

I haven't heard about pinch-rollers going bad/wearing out, but I guess with enough spinning around (under pressure) onto the grit rollers they can do that eventually.

Did you replace the entire assembly or just the rubber wheels? Just curious, how you did that. Maybe it'll help someone to see what was involved? (tutorial/demonstration)

When I bought this machine back in 2015, i was habitual of keeping the rollers pressed on to the grit rollers, sometimes with or sometimes without the vinyl film in between them. It caused the rubber to deform over a period of time. What I have learnt is not to keep rollers pressed for long

Yes, I only changed the rubber rollers, not the whole assembly. I found them on Ali express. The machine I have had 17 mm dia and 10 mm wide rollers with 4 mm as the bearing's ID. They were held on to the assembly using a pin going through the bearing hole with a circlip at each end of the pin.I took the circlip out, pulled the pin from one side, pulled the old roller, pout a new one in, pushed the pin through and refixed the circlip.

Otherwise, you can get a complete assembly as well which you need to insert from one side of the machine

Please have a look at the photos

-

-

-

No idea, can't see what you are talking about.

Is the 'printed design' on vinyl perforated material?

Heat gun is my best guess.

If it is perforated material, it should come off quite easily provided you have got a steady pull of the hand and the vinyl hadn't gone past the shelf life or got damaged due to prolonged exposure to the sun, the latter is obviously beyond control as it can'y be judged.

However, most likely, your guess of perforated mayerial or one way vision vinyl seems to be quite logical. But as ai said one way vision vinyl comes off quite easily provided you have a steady hand and pull it out on a warm day. Otherwise us heat gun a try

-

Ok I can’t get the pictures to attach for some reason but it’s a business window if that helps that has a printed design on the whole window

Most of the times, pictures don't attach as they are quite bigger in size due to ever improving camera lens over the phone. A good idea is to compress the pictures using an online compressor tool or resize them.

-

were you doing vehicle wrap in open air?

For wrapping, it is recommended to do under a shed with a clean ground. Cast vinyl is a bit harder to deal with than calendered vinyl. It is preferable to have an enclosed factory space for the same

-

Is the WRITE PORT ERROR happening in between the cutting program or the cutting is not able to start????

In former case, it would be due to a long program being run at slow speeds or static charge messing up with the cutter. Believe me, I have chinese version of creation pcut ct630 with flexi 10 starter and I usually have the issues every now and then.

In latter case, it would be due to the unreliability of a USB adapter. See if you can get a serial port to serial port cable and use it to communicate with the machine.

Also, as Skeeter said, try not to go for COM PORT higher than 4.

-

This is one of the files that has messed up - It's the one pictured for "DIV 7" (i.e.: Division 7)

I checked the file. It seems to be fine

-

Just curious - the laptop that is running our plotter doesn't have a serial port on it - are you on a computer that actually has a native serial port, or are you using a USB to RS232 converter?

I have a workstation that has an old configuration just enough to keep the machine going without any unrequired movements. believe me, a cheap workstation with a usb hub hooked on for transferring the files using flash drives works wonders

-

Also,whenever you cut the media that has the tendency to do such weird things, please stay near it and looks for some abnormal movements or sounds. If this problem is due to the machine losing position due to some motherboard component malfunctioning, improper connection or static charge present in the vinyl roll itself, it will make some abnormal sounds before messing the cuts up.

There happen to be many posts encouraging people to switch to Serial Connection ports rather than USB Ports. In case you don't happen to find a suitable cable, try getting Tripp life Keyspan adapter that can connect the serial port to the computer

In the meantime, I will have a look at the file

-

-

It's on a USB cable. I think it does have a serial connection, but will need to verify. That gets in to I.T. stuff at the State which can be difficult - but we will check. I think sharing the file may be OK - it's just truck and division numbers - but again - will have to check. Thanks for your reply and info.

It will have a serial port, most of the times, very next to the USB port. The only different thing is, the type of port it has, whether a 9 pin port or a 15 pin port. I will give your file a go, its just, I am struggling to open vdoc files as I do not have the software with me. But, I will have a look at the file. The only reason I asked to have a look at the file is most of the times, it comes with a lot of hidden layers whenever we work straight from the client files.

-

What type of connection port it is? USB or Serial. My machine used to do the same thing until I switched it to the serial RS232 9 pin port. If you happen to have that port on your machine, give it a shot.

Morever, if you think it is right, you can share the file so someone can look for hidden layers and objects. Also, when the cutter is in operation, get someone to stay near the cutter and listen to some abnormal noise it might make before messing up.

-

1

1

-

-

This please

in Fonts

The folks who do Graphic Design for logos aren't signmakers. They have no perspective on what is required to make a sign using cut-vinyl lettering. In their world, everything is Printed (or reproduced on websites) so Raster output is usually fine.

The worst are those clients who hand me a business card and say "Make my sign look like this"

Uh, no.

In this case, I would ask them for the file for the card or the font name. If not provided, I will disclose them of charging a designing fee which is obiviously a bite into their wallet. I also tell them that it will be close but not exact. It automatically rolls the ball in their court

Believe me mate, it worked a couple of times with me and I ended up getting a proper file to start working with.

It is worse to work with such clients. I guess, you didn't have to deal with graphic designers and architects who are given the charge of producing the signage just because they designed the fascias and are thought to have ideas about signage and their mounting.

-

It depends on the actual dxf file. The truck is, they need to be imported woth the shapes joined as polylines and not exploded. It looks like the dxf you got came to you in the exploded state so when you imported it in VM, it tool a chunk off the main profule depending on the accuracy you selected on your VM sofrware.

Would you mind sharing your file here and I can have a look on the file for you??

I work with dxf all the times and use Flexi for the cutyer. Never had any problems.

Another thing I can think of is the AutoCAD version dxf file is saved as.

-

Hi everyone

Thanks for the suggestions

Slice & Dice! You're right, Mercury is theaccused

I posted the same query in some facebook groups as well. These are the responses I have got

https://www.facebook.com/groups/vinylcuttingforum/permalink/3461367504128165/?comment_id=3462051917393057¬if_id=1688156898613071¬if_t=feedback_reaction_generic&ref=notif

https://www.facebook.com/groups/327464755215909/posts/948663899762655/?comment_id=949064656389246¬if_id=1688146572524782¬if_t=group_comment

-

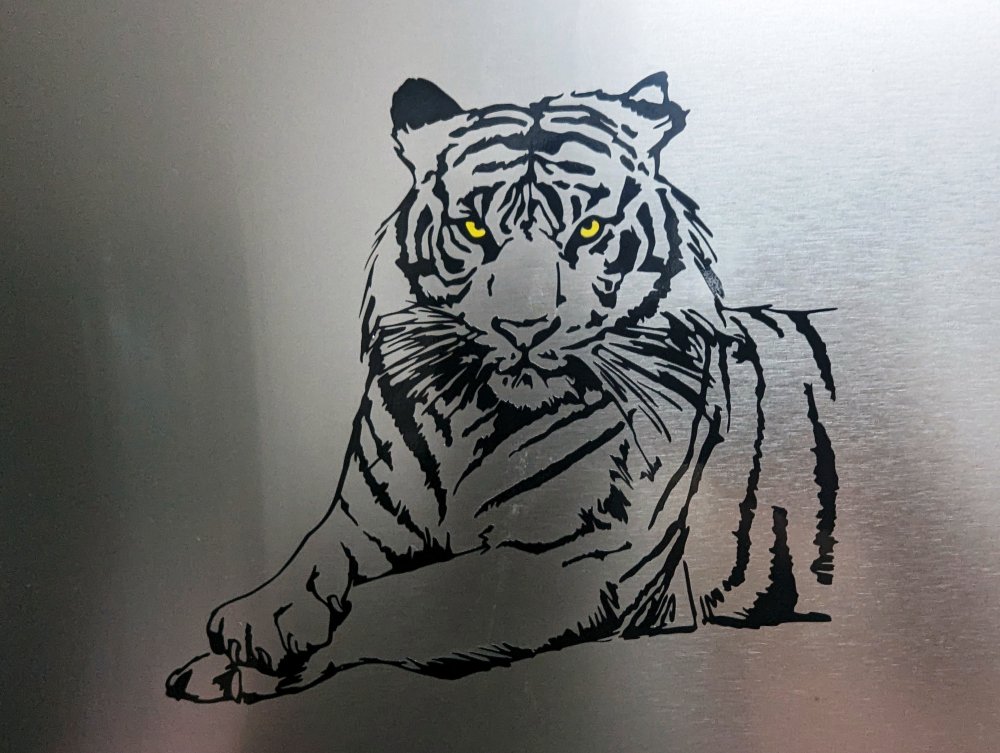

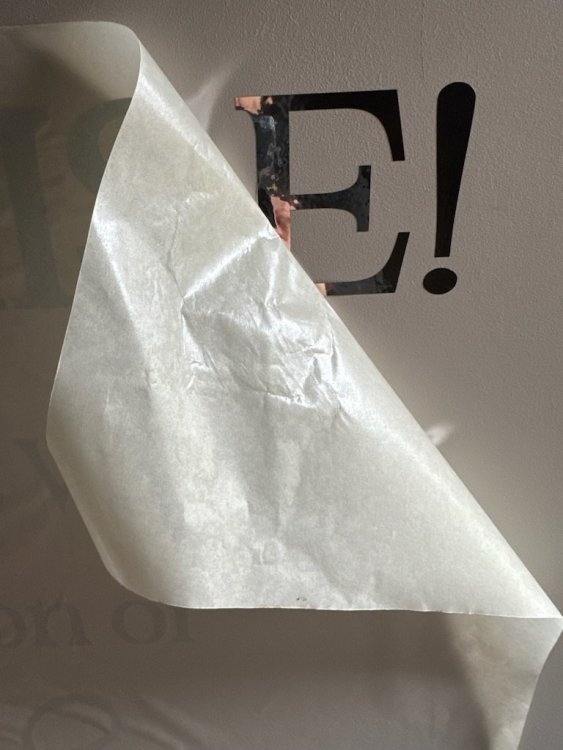

Hello everyone

Just curious to enquire has anyone else faced the problem of decals not sticking to a painted surface in extremely cold weather?

Mercury here in Australia is dropping down to 2 to 4 deg celcius and I have some complaints from some people that Mirror Gold and Mirror Silver decals are coming off with the tape.

I have used low to medium tack tape (Politape 130) and the back board was painted a couple of weeks ago before the decals were being stuck.

Also, the decals were applied dry.

I tried the same stuff on the painted wall (as it had similar texture) and didn't have problems while putting it on

I am attaching some pictures for you to have a look on to. Please be mindful it is not an acrylic backdrop and the other colours on the same board got stuck seamlessly.

Any input will be highly appreciated

-

It seems like it has something to do with the feeding rollers, looks like the cutter is not coming back to the same position in case it goes off to another part of the sheet for cutting. Or it might be a static buildup. I use flexi sign for cutting and the way I was able to overcome this issue was restricting a margin of the sheet for cutting at once. I gave a value of 5 inches x 5 inches. So the machine cuts everything it can within that margin before moving to the next part.

See if you can work something out similar to this in your software

-

Obviously, you need to cover yourself up for some stuff ups as well. Please make sure that margin is included. If it is used up, you are covered, otherwise, you are more than free to either keep it with you as an extra margin for yourself or pass a bit of it to the customer in case you want to look after him because of he being with you for quite a while

-

I checked the earlier threads started by him. You're right. He has come multiple times with nearly similar logos and same sort of questions.

Pdf can't be used to cut directly but being in Portable Document Format (PDF), it is one of the lightest file to transfer data over internet. Signblazer does accept EPS files which can be made in Illustrator and many other programs easily.

-

Hate to say this, Kainth, but what you did there is not very useful, at all, from the standpoint of providing what was requested.

.pdf? How is that even cuttable? He wants an SBD file, which I could make in two minutes, but I won't.

In fact, I think this poster is just messing around with us, he was here with the exact same 'threepers' militia logo in 2020.

For the record, Three Percenters have a track record of criminal activity ranging from weapons violations to terrorist plots and attacks. (according to the ADL, the Jewish Anti-Defamation League).

He was given the exact information he needs to do his own cutting file.

If he can't manage it, that's his problem, not ours. -

Have a look at this. Simple shapes like Circle and the percentage symbol can be recreated. Also, the text can be typed on the path. You just need to tweak around with the helmet and the outline

White teflon strip required for CT630 Creation Pcut cutter

in Creation PCUT Cutting Plotter Support Requests

Posted

Ali express is where I got these strips from. If I put something underneath the 1.5 mm strip to increase its height, it may not fit into the channel as the strip is not glued but inserted into the channel.