-

Content Count

143 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Gallery

Everything posted by PhaedrusZen

-

Shredded letters... =/

PhaedrusZen replied to PhaedrusZen's topic in TITAN 2 Series Vinyl Cutter Discussions

Really appreciate the replies and ideas! My cutter has a Roland 45 degree blade in it. The cutting strip is super clean, and I've never run off the vinyl, so it shouldn't be dinged up or anything. The vinyl is cutting through cleanly, with just a faint mark in the backing paper. I checked the pinch rollers just in case that was contributing, but I didn't see anything unusual there. I use all Oracal 631. All my problems were with a 50 yard roll of white. I tried cutting the same design with a different color, and had no issues at all. I finally got the white cut out, but that was after sitting right in front of the cutter with a pick and pressing down each letter as it got stuck or shifted from the blade. Nasty to weed. I cut two more designs out of the white after that, and they cut, no problems. So stumped. Crisis averted for now, but I'm really hoping this doesn't happen again, and can't figure out why it did what it did. If I see it again, I'll definitely try pulling the blade to clean it and oil it a bit. I uploaded the file for those of you that were curious, complete with the weeding lines I was using. It would catch on a variety of the smaller letters, with no issues ever on the "Love Story". The V and Y in "Every" would catch or tear really bad each time, with the other letters causing problems at random. Thanks again so much for the replies. I'll keep you posted if this happens again. Aside from the occasional errant weeding line, I've been really happy with the Titan 2 and SCALP combo, but this issue cost me probably 6-7 yards in material, an hour or two of wasted time and a lot of frustration! (Especially at 2 am...) Trouble File.svg -

From the album: My Personal Projects

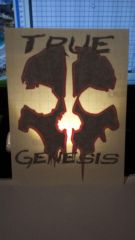

I got bored and wanted to learn some stuff. Created an SVG file from a Call of Duty logo, and added my friend's clan name. I wanted to try layering a decal, so I ended up with 3 layers on this one; The red background skull, the black lettering and a gray skull shadow on top. I'll have to see how it looks applied to something. =)© The skull is probably copyrighted from COD, I guess...

-

Weeding lines cutting through some letters occasionally

PhaedrusZen posted a topic in Sure Cuts A Lot Pro

I'm working with a registered version of SCALP, so this isn't a watermark issue. =) I've recently cut a bunch of large names out in 3-4 different fonts (12"x30" or thereabouts), and have been using weeding borders around individual words with a single weeding line dropped through the middle of the word horizontally. For the first 75% of the orders I had no problems, and then had a single issue where the weeding lines cut slightly into the letters, but not enough for it to be a huge deal. Then, I had a project where it inverted the weeding lines, cutting right through the letters, and not in the dead space between letters, for about half of the name. Having to have trashed 2 projects I've quit using the weeding lines, but am keeping the border. Anyone know what might have caused that, or is it just gremlins? -

So, first of the orders shipped, and 2" is REALLY tight. I'm hoping that they don't get damaged, but hey, the boss gets what the boss wants... I did learn a nice new trick. When I asked my employer about shipping in the tubes, she told me I needed to place masking tape on both short edges before rolling to keep the transfer tape from coming up. It was adding additional time to the process, and I realized that instead of doing that, I can just trim the top and bottom of the decal and leave about an inch of transfer tape overlapping on either side, then just fold it over. Presto, edges taped, and no massive quantities of masking tape needed! It also makes use of the inch or so of overlapped tape I've been laying down past the decal to keep it in place while applying the tape.

-

Order of Operation

PhaedrusZen replied to PhaedrusZen's topic in Business Practices, Sales and Pricing, etc.

I've been resetting the origin thus far; I was wondering if it would be worth the saved time to stop doing that, but I realize that 5" is no small amount to waste on each cut, so I'll probably keep resetting. Has anyone tried packaging as they go or anything like that? I'm really looking for ideas that can save me time over the entire operation. I'm still experimenting, to see if it's faster to cut a single piece, weed it and apply tape, or if it's faster to group things together. Trying to stay organized is a challenge too. I end up with 2-3 lists with highlight marker all over the place... it's a massacre!- 8 replies

-

- efficiency

- time management

-

(and 1 more)

Tagged with:

-

Alright, I've only been cutting vinyl for about a week, and while I'm still experimenting with the basics, cutter setup and everything else, I'm really trying to figure out how to streamline my operation. Any experience with organizing a large cut list to maximize efficiency? I just shipped out 92 orders in 3 days, have another 100+ that need to go out in 2 days, and then another 150+ lined up for shipment by the 22nd. I'm putting in 12+ hour days on top of another full time job and need to get a handle on the work. ANY tips are much appreciated. As much as I'd love to peruse the forums more for ideas and tips, I just don't have the luxury of time right now. (Typing this up is the longest I've sat down all day, and that's after coming off a 24 hour shift...I'm dragging!) Right now I think it seems to work out well, to cut out all the orders for one color, then weed, trim and get transfer tape on them. Is it more beneficial to cut everything out first (all colors at once) or to keep breaking it up like this? Obviously I'll keep experimenting to see what works personally, but if there are some easy tweaks I can make that will get me cranking out that much faster, I'd rather learn about them sooner rather than later. Thanks!

- 8 replies

-

- efficiency

- time management

-

(and 1 more)

Tagged with:

-

You guys are making me cringe. I'm working for someone else, who orders all my supplies. I've currently got large decals (about 36" long and 18" tall) taped and ready for customers to apply on their own, that should be ready to ship tomorrow. I've been using Oracal 631 with Oracal high tack tape. I've got 130 orders, so I don't think custom cutting boxes is feasible for me. At this point I'll have to cross my fingers and hope for the best. I'll let you know if I get any customer feedback on the shipping with 2 " tubes. As for the original question, I'll be doing vinyl out. Appreciate the feedback!

-

Order of Operation

PhaedrusZen replied to PhaedrusZen's topic in Business Practices, Sales and Pricing, etc.

Skeeter is right, I'm a hire-on for a home based company. A friend of mine has way more work than she can handle, and I'm the third cutter she's hired. (Don't worry, I know I'm spoiled.) I'm not really struggling with any single aspect. I'm getting faster at applying tape and am down to just the occasional zipper here and there. I'll give some specifics of how I'm running a job and see if I can't get some feedback on the process... I have two SCALP windows open, and while one project is cutting I lay out the next one so it's ready. I'm using a zipcutter to cut the graphics off, and I reset the zero point after each cut. (is it worth writing off 5" of vinyl that advances between cuts? Seems like it wouldn't be.) I've been cutting all projects of each color at once, and then taking them all to the table. I have a weeding border around each individual project and try to cut 2 projects each time I cut (using as much of a 24"x48" mat size as I can). I weed out inside the border, trim the excess for "remnants", and then put it aside and do the next one. Once they are all weeded and trimmed, I start applying transfer tape using the "APProller" for longer projects, and using a roll of transfer tape that feeds from the bottom for smaller decals so I'm placing the decal down on the tape and not vice versa. For larger graphics I use the mondo trimmer, which is unwieldy and is tearing the crap out of my cutting mat, but gives me clean edges fairly fast. For smaller projects I use a rotary trimmer with a ruler or just freehand it. I was originally given just scissors and an exacto for all the trimming but I can't keep a decent straight line for the life of me. I squeegee the decals after I've cut them out of the transfer tape. When I started, I was squeegeeing before cutting the decals out of the rest of the transfer tape so they didn't move, but that lent itself to a lot of wrinkles since the excess tape had nowhere to go. I'm at about 3-4 minutes to apply tape to a weeded 18"x34" decal, including cutting it out and squeegeeing. Not sure if I'm overdoing it on the squeegeeing, but I really don't want customers having issues with lift off. Then it's on to packaging and shipping, which is it's own type of fun... Not sure if there is anything in there that might help identify some faster methods for me to try, but have at it. Back to the sweat shop! =)- 8 replies

-

- efficiency

- time management

-

(and 1 more)

Tagged with:

-

It can help with weeding the really detailed projects, but I built it with the thought of creating layered decals. This way can flip the light on and see how the layers are lining up to each other. I don't use it often, and most of the time the table has a cutting mat covering most of the top, but there have already been a few times when it's come in handy. I've got plenty of light above the table as well. =)

-

Work on one project while another is cutting? (SCALP)

PhaedrusZen posted a topic in Sure Cuts A Lot Pro

Maybe this is obvious and I'm missing it, or perhaps it's just not the way the software works, but I was wondering if it's possible to cut one project and open a separate workspace and begin laying out the next project. I've got jobs with multiple components that I import and arrange before cutting, and it would be nice to work on one layout while the other is cutting. Any ideas? Thanks! -

Work on one project while another is cutting? (SCALP)

PhaedrusZen replied to PhaedrusZen's topic in Sure Cuts A Lot Pro

Awesome! That'll keep me productive during some of the longer cuts. -

I just set up a Titan 2, and cannot get the vinyl to feed off the roll. I double checked the pinch points on the rollers, and without vinyl in the machine I can see that the grit rollers are all moving. When I try to jog the vinyl to check tracking, the roll doesn't move at all, but I can hear the grit rollers sliding against the back of the vinyl. I'm using a 24"x50 yard roll of Oracal 631. I need to hopefully start cutting today, and am stuck until I figure this out. Any tips would be appreciated!

-

I went off the hand-cutting test for blade depth. My first cuts were just barely too shallow and weeding was a pain. I upped pressure from 50 to 99 and readjusted the blade again, and now it cuts like butter.

-

Got it figured out... I was going off the Material loading guide from the USCutter website, which uses the same "U" shaped stickers in the guide photos. The meaning for the stickers, however, is the exact opposite on the Titans, since apparently the guide photo has a huge grit roller, with a small dead space, and the Titans have a huge dead space, and a smaller grit roller. I figured it out while waiting for Technical Support, which were really nice by the way. Chalk it up to my excessive "noobie-ness". I've never even seen a cutter before, so all I had to go off of was the photos. Doh! Thanks for the tip on giving extra on the roll. I probably would have let the cutter do all the work. Here' the guide that caused me problems... http://www.uscuttersupport.com/downloads/Support_PDF/CutterSetup/Material_Loading_Guide.pdf

-

From the album: Home Workshop Setup

A work bench I made for myself. I made a wood table frame and used a shower door from the Habitat store as the table top. I ran an LED bar light underneath on the right side so I can use the desk as a light box for aligning multi-layer pieces. My cutter will go on the wall to the left of the work bench. Three shelves on each end of the table and pegboard on the wall provide tons of storage space. The two tier dispenser on the end would let me run different tack papers at the same time if needed. All said, less than $100 for this project. -

Pulled the trigger today

PhaedrusZen replied to SmallSigns's topic in TITAN 2 Series Vinyl Cutter Discussions

Perfect. I'm just going to preemptively order that sucker. I love Prime shipping. Should show up the same day as my cutter, if I'm lucky! =) -

From the album: Home Workshop Setup

Detail of the clips I use to make sure I know which vinyl roll is which. Also simplifies reorder. -

Pulled the trigger today

PhaedrusZen replied to SmallSigns's topic in TITAN 2 Series Vinyl Cutter Discussions

I'm just starting to work for a friend cutting vinyl, and have a Titan 2 on the way. I was wondering if anyone could tell me how long the USB cable that's included is. My workspace limits my setup options, and I might need a cable as long as 13-15 feet, depending on how the Titan sets up.