Jburns

-

Content Count

726 -

Joined

-

Last visited

-

Days Won

9

Posts posted by Jburns

-

-

Thats a tough one - I could not find it . used Find my Font

-

sorry to hear that... I would try what Slice said above.

Also since it stopped during cutting, and NOT on a dry run ---it may have some have trouble with static- is your area a dry climate, ( below 40%) humidity? When the blade touched down, it may have been static from the vinyl ( I know it may sound strange.

Some run dryer sheets in the tube, wipe the vinyl down with them, add a ground cable from cutter to stand, run a grounded thin cable across the roll .... there are some other posts on static topic.

-

Thanks -others will chime in with that software, but I would try cutting simple shape files-- if it completes them, then:

Try the serial cord if the plotter came with one. If so I would try that. - hopefully your computer ( or docking station) has a serial port. (if not check out keyspan adaptor).

I understand you may not think its memory related...but memory is a common cause of your description - but worth a shot on the serial port. Serial typically allows a give and take relationship (CTS, RTS commands) for the file size.

Or look at your file in wireframe- a trace may have loaded it up with tons of nodes- some software may allow you to reduce the number of points- thus make the file smaller ( I think).

-

Hello,

which machine and software are you using? Also - are you connected thru Serial or USB?

-

typically I used to reset the origin before the second job...that should do it. . - but your software may have another option-- what software are you running?

-

Welcome! plenty to learn, and enjoy!

-

thanks skeeter- I liked mine also on the other Graphtec I had. - yes- the 75 version.

-

1

1

-

-

nope- no catch basket. it might be sitting in their shop somewhere - I should probably ask.

-

1

1

-

-

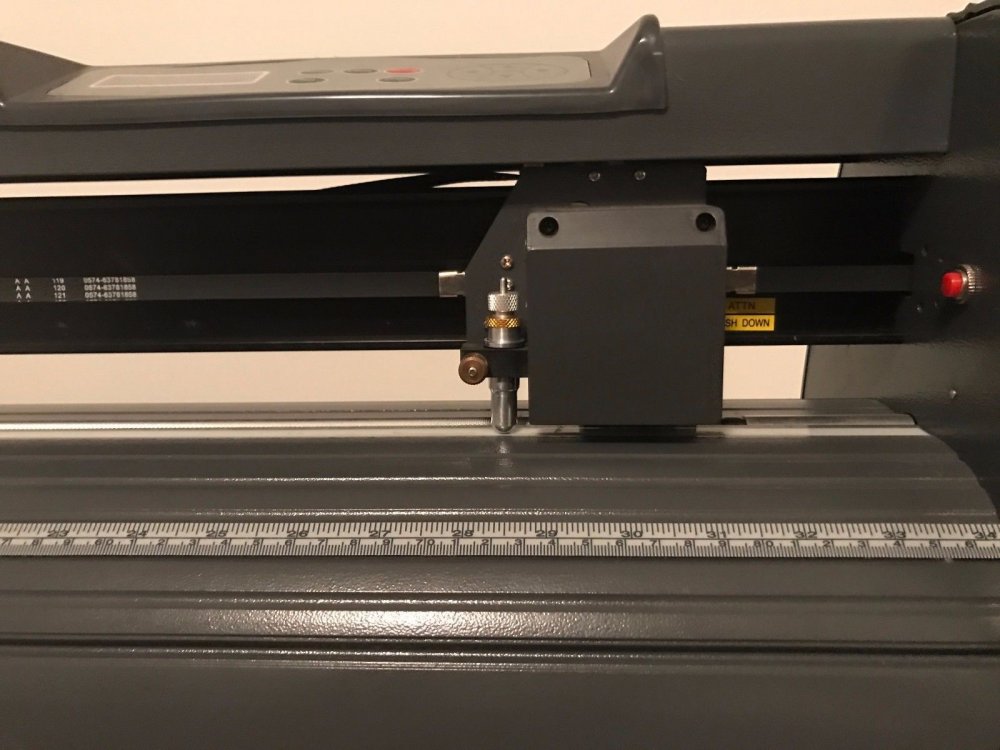

You know, on some days we all can find a good deal. I am always searching for printing / and plotter equipment, and yesterday was a good day for me.

The story on this plotter - was purchased by a sandblasting company years ago. They tested and tested, and it didn't cut the rubber to their satisfaction. So it sat, and sat for years.

They put it up for sale, and within a day I made the purchase. All tests are fine. This is the third FC series I have owned- always surprised by the height --48 inches tall

Graphtec FC8000-75. $500.00

-

5

5

-

-

-

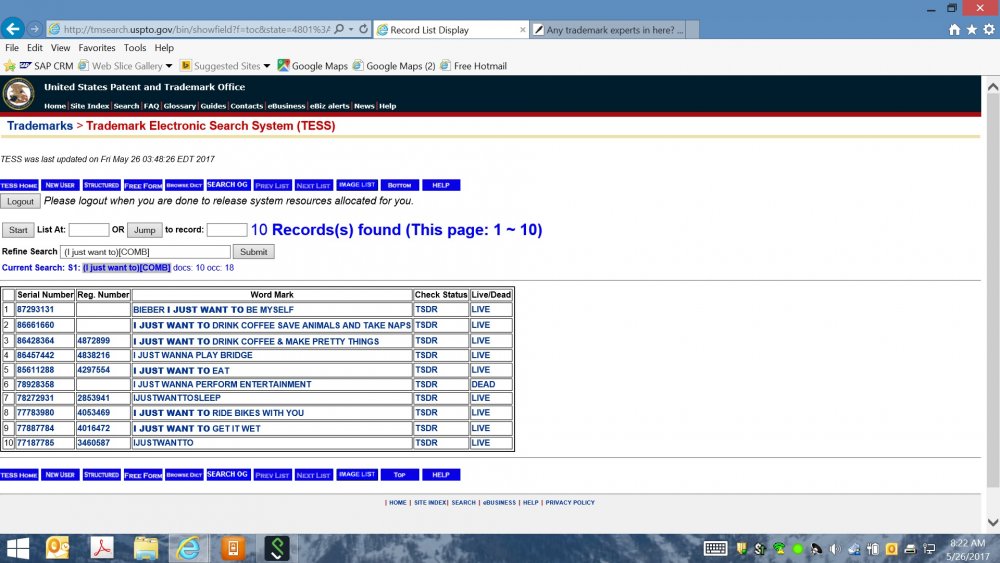

I am not an expert, but here is a screenshot of filed trademarks -I see ten-- I don't see one that says "I just want to" by itself. Its a pretty generic term.

-

1

1

-

-

Selling one of my thermal vinyl printers. For those who are considering decal printing, I would be happy to discuss process. I have been working with these printers for about three years, and owned about 8 or so. This unit uses Gerber Foils for pigments.

It prints on Oracal 651, 751 etc 15 inch punched vinyl. It can print white on clear, chrome and lots of cool colors. I also have software available (535.00 on ebay) and a plotter for contour cutting if interested / needed. I can include 6 or so color starter foils.

$2,300 - 320.00 for shipping ( includes case deposit and return UPS label).

Machine prints great. A few notes:

1. Condition- good - very clean.2. Print test- good- no bad pixels. Registration for multi color- good - see picture.3. Good Shocks.4, Vinyl Squeeges and platen- Good condition.5. Power cord, vinyl roll holder and parallel printer cable included .6. LCD screen CLEAR.7. Plastic top and front cover in Good Condition.8. Will be shipped in Fiberglass and Metal Case with padding. Head will be secured to frame to avoid movement.9. Printer and case weight- about 95 pounds. Case Deposit of 250.00 and UPS return label Included in Shipping Cost. Signature required UPS ground.11. No software or other items not seen in pictures included. See my Software for sale in separate listing.Shipping to Lower 48 States Only. -

Boy, there are so many pantone blues -- I have the newest chart - I think 2017.

I would say for Oracal 067: Pantone Dark Blue C, Pantone 661C, 287C, or 2147C

For Oracal 073- Dary Gray -: pantone Black 7C, or Cool Gray 11C

-

Nice! you made your own null cable

-

-

2 hours ago, mfatty500 said:Try putting the transfer tape on before you weed, remove from backing paper and then weed and put back on the paper. Reverse weeding, if you will

This this would be a good approach also---I used this method when doing hobby / RC car items

-

2 hours ago, jmas said:That's what happened. I work in a body shop and even small 1/16th vinyl pinstripes do that on fresh paint. We usually wait a month before applying larger graphics.

Wow good to know

-

welcome,

I see that the material is 7mil, and reflective can be demanding long term on machines.. I think you are correct to go the servo route. If these are for vehicles, long lengths etc in reflective- the certainly a used (checked) Graphtec FC or other similar Roland Camm-1 would be suited/ made for those jobs.. you want the long cuts to be clean, tracked well and closed.

-

I vote for the bottom two

-

I have had success with ecrater stores- limited layouts- but darn near free to use.

-

1

1

-

-

Actually, now I see more colors...

-

4 hours ago, mark-s said:Mark, that is actually a very nice trace for first round -- I looked at in CS6 and Omega...I would thermal print spot white and the tan color on clear for smaller decals.

But for a large window, layered vinyl onsite would work best, or eco-solvent print. Primal I will run a sample for small ones if you are interested.

-

for kicks - I downloaded from the link from Slice above, FEB 20, opened up the program and found the redsail cutters in SETUP.

-

Machine stopped mid cut...

in General discussion

Posted

What I did when i had a similar cutter, ran an automotive 12 or 14 GA wire attached to existing screw- to another screw on the stand.(sanded away paint for good contact) - also I bought an aquarium grounding probe- it plugs into the wall outlet, and i use to to ground myself before touching the machines ( running vinyl cutters, and printers). I get a discharge almost every time before i touch the machines LOL

LOL

We both live in dry states. and static hurts electronics

Here is the one UScutter sells.

http://www.uscutter.com/Anti-Static-Kit-for-Vinyl-Cutters