-

Content Count

17,517 -

Joined

-

Last visited

-

Days Won

498

Posts posted by MZ SKEETER

-

-

Which cutting software are you referring to? The cutting software with an activation code is only for the original buyer. It would be registered to the Original buyer and cannot be transferred. Signblazer is free abandonware, if you can find a link for it. It is older and many still use it, your CE7000 won't be on there, but many are using an older Graphtec 50 for newer Graphtecs set ups.. Or purchase Vinyl Master. https://www.graphtecamerica.com/software

You "might" be able to get software here, after you register. https://www.graphtecamerica.com/register-gs2

-

Have you checked the youtube videos? The cutter is a rebranded Saga vinyl cutter.. From what I have read, people seem to like the Titan 2 and 3 vinyl cutters. And they say good quality cuts. Those 2 have servo motors. It all has to do with getting a correct set up of blade depth and force, just like any other vinyl cutter. As far as speed, personally I cut slow, no need to run fast. It's not a race. We have OPs come in here and complain about new Graphtecs and we pretty much have to steer them into setting their blade depth correctly. That is the first thing that you have to get correct. It is posted on this forum hundreds of times. You do not use a credit card or post it notes to set your blade depth. That is about 10 times too much blade exposed out of the blade holder. It is a myth that just won't die. Even USCutter still puts that in their instructions, it is wrong. It looks like Titans are on sale. As always, buy the best that you can afford.

https://uscutter.com/TITAN-3-Vinyl-Cutter-ARMS-28-53-68-inch/

-

Down there in Sanford Florida, you can walk into a local Sign shop and ask for their help. Most retail signage places are implementing Flexi in their workflow.

Quite the drive to Florida.

Their Facebook current page has them located in West Virginia. A poster is even thanking Sissy. Dot come page is West Virginia.

Their Facebook current page has them located in West Virginia. A poster is even thanking Sissy. Dot come page is West Virginia.

-

No, you would need the Flexi software to export as a different file format. Tell your customer to contact the creator or you contact the creator and send them in a format that you can use. Most would export as an .eps. Which can be used in most softwares. You would probably not even know which version of Flexisign pro that they used. An older version of Flexisign Pro cannot open newer files, or only up to a certain version. My Flexi software (10) is older and cannot open newer Flexi files. A newer version can open current and older files. It looks like they are up to version 22 now.

-

Making your software work with the vinyl cutter is a Vinyl Master or UScutter job.

Are you using 1 blade holder for both processes or 2 different blade holders ,blades set individually for each process? The process I have read with the Graphtecs, is to use 2 different blade holders. 1 is set for the contour cutting. I is set up with blade extended further out of the blade holder for the perf cutting. They don't change the force, maybe just a little. Blade holders/blades are preset to cut, for each option. with the blade in them. Just change the blade holder/blade, for each process. That's all I can add. There are only a handful of forum members here that answer questions. None of them have a Titan 3 vinyl cutter. Maybe some one else can add something.

-

Check Copam. Many of the old gang didn't want to learn new software.

-

I don't have a Titan or use Vinyl Master BUT are you using a cutting mat under your vinyl? You would have to, or you would be gouging up your teflon cutting strip, if you are cutting all the way thru the vinyl. Or are you not cutting all the way thru? .Plus dulling your blades very fast.. The newer Graphtecs have a dual place blade holder, and the perf cuts are done over a channel, so as not to harm the cutting strip. I didn't think a Titan 3 had that, or could perf cut. I may be wrong, but newer Graphtecs, and Summa can perf cut.

Looking at that video of UScutter. Vinyl Master, it looks like they have PrismCut vinyl cutter loaded up in the software. It may perf cut. Ask UScutter if the Titan 3 can perf cut. I see several questions being asked in the forum about The Titan 3 cutting thru and perf cut, No one is saying that it can.

-

Did you ever try a different cutting software other than Studio 2? That way you can figure out hardware or software problem. Signcut has a trial. Sure cuts a lot has a trial.

-

1

1

-

-

Without seeing the cutter file and your settings in Graphtec Studio2, would have no idea, unless you have multiple passes checked in the cutting software. Very few volunteers here answer questions and very few have a Graphtec. And I don't know of anyone who has a Ce7000 or Graphtec Studio 2. Have you tried a different cutting software to rule out the Graphtec Studio 2 as the problem? Several trials out there. File could be posted as long as it is not a violation of Copyright. Post in .eps format.

-

You must show that you made a purchase of a newer Graphtec cutter it looks like. Fill out and register. I had never looked at the ad before,

When I got the Graphtec Pro Studio, I had to register and they sent me the activation code in an email.

When I got the Graphtec Pro Studio, I had to register and they sent me the activation code in an email.

https://www.graphtecamerica.com/register-gs2

If you got your cutter new, you should have gotten the Graphtec Pro Studio, which is over $1000 for windows, made by SAI (Flexi)

-

Have you considered buying used? A Graphtec FC 8000-8600 or 9000 is better than any cutter you posted. Built like a tank. And has the channel in the front for perf cutting. Plus dual place for blade holder. Many times if you have the money, can be purchased cheaper than a new CE7000-60. The FC cutters have great tracking and more force than the CE units as well as the pinch rollers have adjustable pressure.

I don't have a recommendation on your list. The CE7000 is just not preforming up to the standards of the Ce6000 and previous CE units. Is now made in a different country than before. I don't know anything about the others on your list.

-

Did you just buy a new cutter from UScutter and it came with cutting software? If so, check in your package for it. Or check your emails. If you can't find anything, then contact UScutter.

-

The TEST cut has to line up first, or much better than it is now.

-

1

1

-

-

We do not know what you are calling "proper" position for blade depth. But do not use a credit card or post it notes to set blade depth. That is too much blade exposed out of the blade holder.( Too many incorrect instructions out there). If you are seeing the blade tip out of the blade holder, then you have too much blade exposed out of the blade holder. Your cuts look like that is what is going on. Too much blade exposed out of the blade holder.

Try this. It works for correct blade depth. Posted hundreds of times on this forum. Make sure no vinyl is stuck in blade holder, blade spins freely and you can add a drop or 2 of light oil in the blade holder. 3-1 oil, sewing machine oil. etc.

To start with, you should set your blade depth correctly, by taking the blade holder out of the machine, and firmly cut across a piece of scrap vinyl, you will be cutting. You should only be cutting the vinyl and barely a mark on wax paper backing, Adjust blade to get there, Then put the blade holder back in machine, and use the force of the machine to get there, same results, only cutting the vinyl and barely a mark in wax paper backing. You should barely see and feel the blade tip out of the blade holder. Regular sign vinyl is only 2-3 mil thick. You only cut with the very tip of the blade. When you think the blade is so far in the blade holder, that you think it would not even cut, that is probably correct. The correct combo is less blade more force.

-

1

1

-

-

This thread has started to go off the rails.

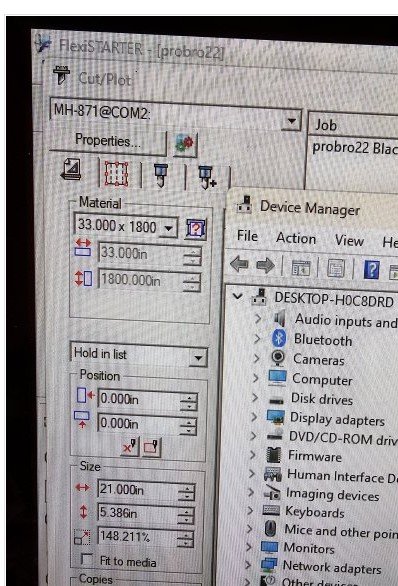

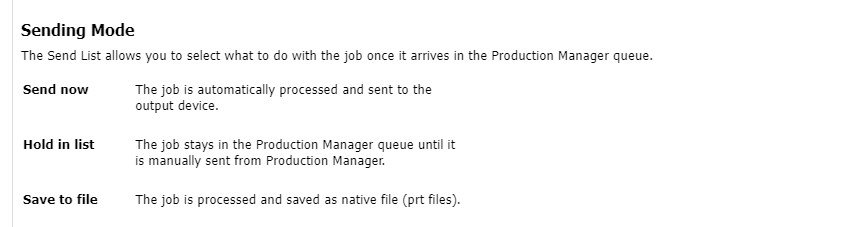

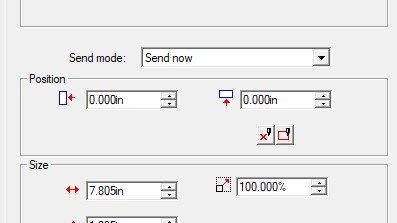

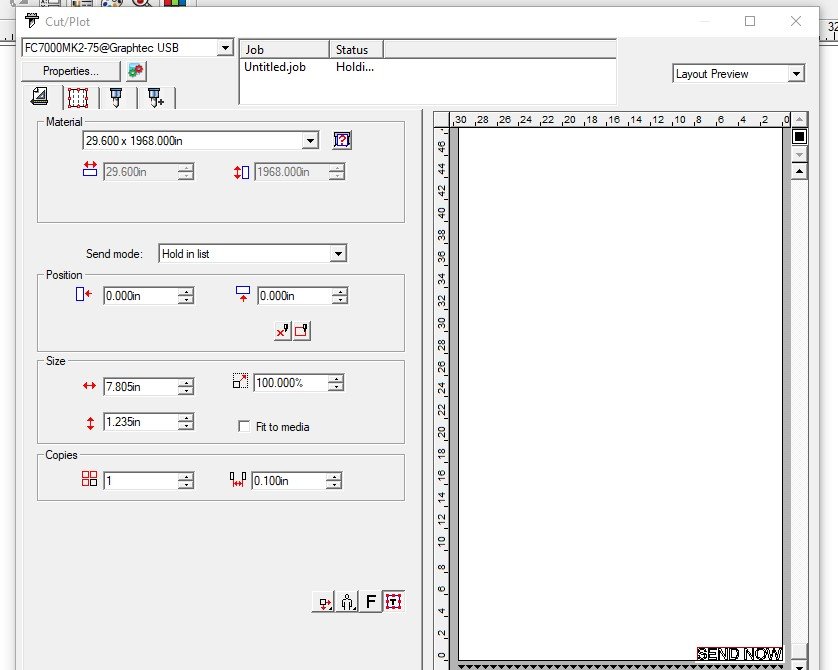

Nothing is off the rails. The Flexi software is doing what the OP is telling it to do. The design will never send to the vinyl cutter, when it is being held in Production Manager. "HOLD IN LIST". No matter what the connection is. The design will not send to the vinyl cutter until it is on SEND NOW. When Flexi software has a communication problem with incorrect com numbers, it throws out a "write port error." ,"cannot open port" When the OP changes to SEND NOW and THEN gets a write port error,, cannot open port, then he has a communication problem between cutter and computer. Look up write port error on the forum. You will see it is always Flexi that throws that error. I always tell those OPs to plug in their vinyl cutter into the computer when the computer is turned off, because it will jump it to another com number, then they won't match coms, if they plug it in while on. Use a dedicated computer and leave it plugged in.

-

Instructions are above for HOLD in List.

-

-

Why do you have the SEND MODE in: HOLD IN LIST? It is doing what you are telling it to. Holding in the Production Manager Que. To Send to your vinyl cutter to CUT is : SEND NOW. If I put my Flexi software on HOLD IN LIST, that is exactly what it shows in my Production Manager Que . HOLDING I do not take my SEND MODE off of SEND NOW. No reason to.

-

If you have the original serial cable that came with the cutter, when you bought it, it could very well be a null modem serial cable.

-

The Tripp lite adapter is NEVER plugged directly into your vinyl cutter. I wrote this in previous post, which is why you need a null modem serial cable, Between the vinyl cutter and the Tripplite Keyspan adapter. The null modem serial cable screws into the Tripplite Keyspan Adapter screw end., the other end of the null modem cable screws into the serial end of your vinyl cutter.

haumana in her post above, is giving you step by step instructions. Follow therm.

This null modem serial cable right here, is BETWEEN the Tripp lite Keyspan adapter AND your vinyl cutter. One end screws into your vinyl cutter, the other end screws into your Tripp lite Keyspan adapter. USB end into your computer.

-

Show the cable connection to your vinyl cutter.

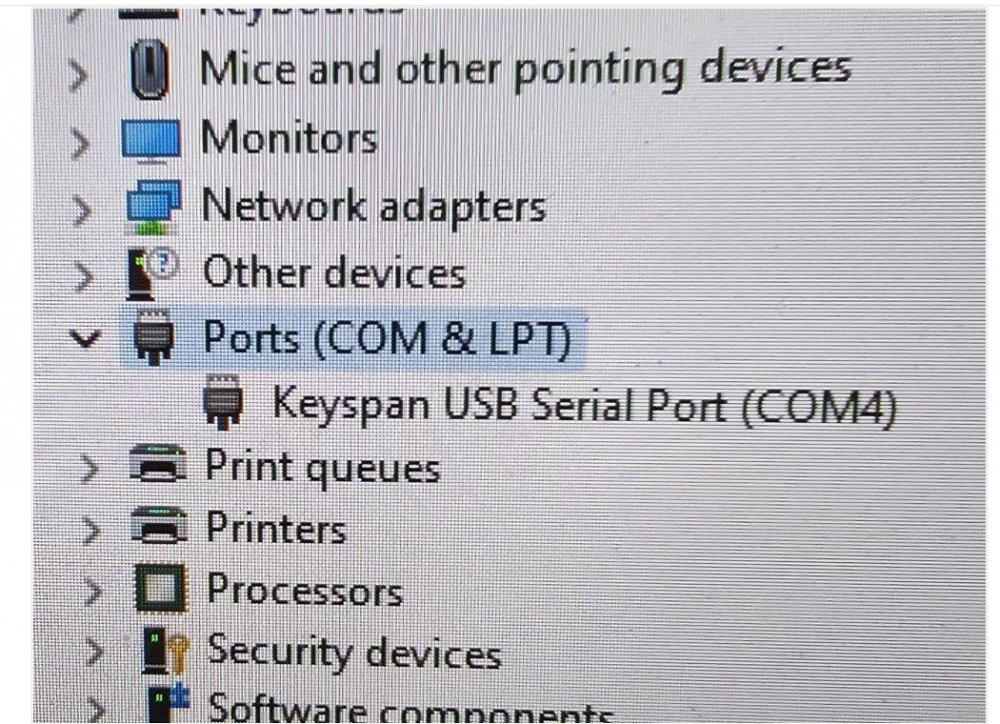

You showed your first picture as being installed in device manager to Keyspan Adapter COM 4, So why isn't it on com 4 in your set up on Flexi? They must match. No reason it should be on com 2. You HAVE to use a null modem cable with a Tripplite Keyspan adapter.

-

You are not showing pictures of what the Flexi Production manager looks like. Show pictures of how you added your cutter to the set up in Flexi production manager, Show those photos. Show photos, not videos. Correct above about you must be using a null modem serial cable. Are you sure it is?

-

Then uncheck MH com 1. in Flexi set up. Start a whole new set up when you get the correct cables.

-

On that short video, In production manager, you are showing you have both of the MH com 1 and MH com 3 are checked. You only check 1 of them, NOT both of them. You cannot be checking Com 1 and Com 3 both at the same time in Production manager. You only choose 1 at a time. Which com port # is listed in your computer device manager? That number is the only com port number that you use. The driver is only set up on 1 com port in your computer device manager, What is that number? What ever that number is, is the same number that you choose in the Flexi set up. You should only have 1 com port checked/ selected in Flexi at any time. Delete the other one. If you are trying to use that USB to serial adapter, you are wasting your time. Most of them have the same cheap Chinese chipset as the vinyl cutter with is pretty flaky. You need get a Tripplite Keyspan Adapter and a null modem serial cable.

I found this in a unit we are cleaning to sell. What is it?

in General discussion

Posted

It looks to be a Saga. Or rebranded Saga, Titan would be blue and sold by UScutter. It should have a model number plate on it. UScutter sells parts for it. And has a user manual for it. People seem to like them, If they are working correctly. ..Depending on model, some have servo motors. Turn the power on it and see if it says on the screen what it is.. You can purchase Vinyl Master cutting software for it. https://uscutter.com/TITAN-2-Vinyl-Cutter-28-53-68-inch/?gad_source=1&gclid=Cj0KCQjw8pKxBhD_ARIsAPrG45mALfiNF25H4lMLXl3RJJTch7u5PWWZrcIPjRMuE3nmoay3ED8Tps0aAmcBEALw_wcB

https://www.aliexpress.com/i/3256801650397084.html?gatewayAdapt=4itemAdapt