-

Content Count

1,956 -

Joined

-

Last visited

-

Days Won

17

Posts posted by xpaperman

-

-

-

-

wow.... 200 bucks? Good for you! Not sure why you would want to use top notch vinyl on a corroplast sign that appears to be temporary. Basically 2 24" x 24" double sided corro signs using 651, I would probably do for about 60. If your corro cost you 35 for the sheet and you using 25% of it, your corro cost is only 9 bucks. A couple more bucks for 651 and little for app tape and thats it. Why did you need velcro? Surely not to take two onesided signs and velcro them back to back to make a double sided sign thus doubling you cost on the whole job.

-

make sure you are starting from the middle and working out. Don't start at one corner and work all the way across. also make sure the app tape is the size of the sign. Don't cut out the middle!! That helps keep it all lined up and square. Also when squeegeing, start out from middle to edge very lightly..... just enough pressure to get it lay down some so you don't get all the water out and set it. Once you lightly go all the way around and are happy with it start applying pressure. By going very lightly, if your not happy you can easily lift and redo and will cut down on creases and wrinkles. You just have to take your time.... you just can't blow through those!

-

6 hours ago, Wildgoose said:Honestly that design is about as simple as you're going to get and a great place to start learning the craft. If you have a cutter you will need these skills anyway so why not take a moment and figure it out.

I was thinking the same thing......

-

I have a color laser printer! I got it free from Conde!!! I got it last year on the big 4th of July blowout sale. If you spent more than 700 bucks I think it was, they gave you a free color laser printer! I just so happened a customer called and I needed over 800 bucks worth of blanks for them! SCORE!!! Its a Ricoh and I have not replaced and cartridges yet!

-

1

1

-

-

Nothing wrong with sign blazer. I have used it since I started. Free, easy to learn/use (does have some limitations) and never fails me. In fact, I still use it today as my cutting program! I have other programs but still use sign blazer. I am trying to ween off of it but sometimes old habits are hard to break. Good luck with you current issue.

-

4

4

-

1

1

-

-

Me? First, I would mark up the product... the numbers. If they cost you 23 cents each (including shipping) I would charge say, 30 cents per letter/number just for the "product". Now, on the labor side, you say a good customer.....how good is up to you, but for me I could do say "by the hour" Meaning either time your job or questimate the time it will take and multiply by the hourly rate you would want to pay yourself and go from there. Just a thought. Maybe that might help.

-

I currently have 2 of those. Work fine. Also have a matching hat press. Of course these are not what I use, but I do have them.

-

1

1

-

-

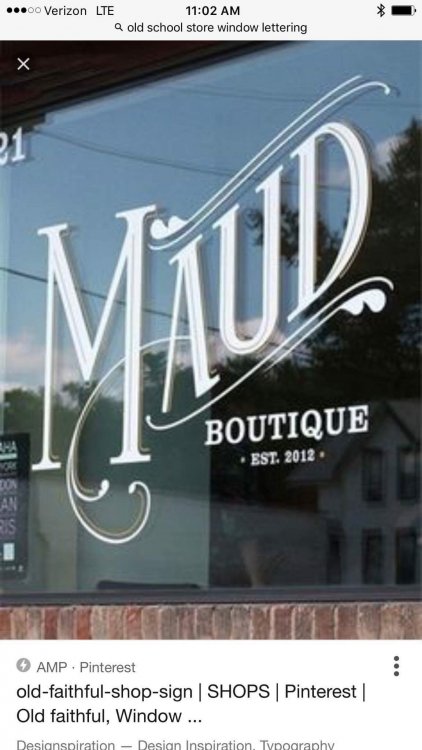

First off, it really took a few minutes to figure out what was going on. It turns out, your in the reflection taking the picture. Also It appears there is a reflection of a light fixture as well..... that being said, it looks like maybe you have a two color job here? Looks mostly black with a maybe a grey unicorn in the middle? It also appears that you either have bubbles in the vinyl in the tree.... or maybe just some water that wasn't cleaned off before photo?

So, assuming 2 color.... the material part is easy to figure out. How much time did you have in the design part?

-

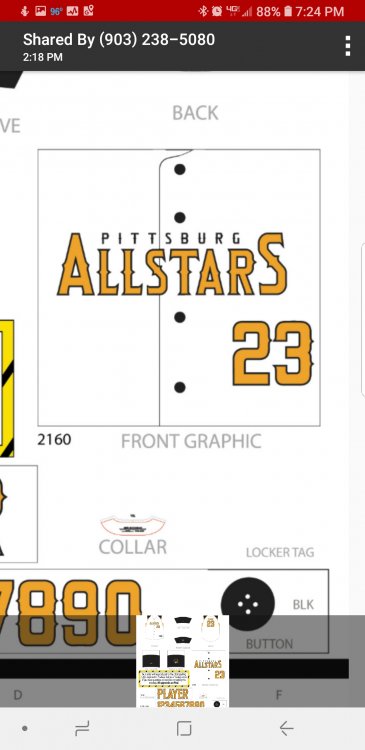

Thanks for the extra effort Primal. I will look into that font and see if we can come up with what we are after!

-

Thanks for the help and info guys..... we will just go a different route then. I was afraid it might be custom, I knew if I asked here someone would know.

-

-

I use 651 vinyl on the hard sided RTIC's and have had no issues.

-

I use invoice2go. It's an app but you can use it on your phone, computer, tablet etc. It does everything. I love it. there is a trial version but you only get like 5 or so invoices to "check it out" I just pay the fee and use it full time. Worth it for me!

-

Are you needing exact? I was googling and saw some things like it.... or like separate pieces you could put together.

-

I like that color combo

-

I tend to shop online after a few "beverages".... They next week or so in very fun!

-

2

2

-

-

Howdy from Texas

-

I am not exactly sure whats going one but you should really never have to replace your blade holder under normal circumstances. Plus, a blade on 651 should last quite a bit longer as well I would think.

I might try a smidge more blade to keep the holder off the vinyl and with that a little less pressure?

I have never had that problem so that is just a guess. Something to try maybe until someone else comes along to help you out.

-

howdy from Texas! (Pittsburg Texas at that) Good luck on your goals. There is tons of help on this forum!

-

Yes, the SC model is very tricky to get set just right. It's a learning curve. However, once you get it tweaked just right I think it is one of the better lower end machines! You can get some good small stuff out of it with practice!

The downside? It seems like once you get it perfect.... it's time to change the blade..... UUUGGGHHHHH. LOL

-

2

2

-

-

another tip.... make sure you clean the glass first! Real good. You want to make sure there is no "film" or dirt of any kind on the glass that you cant see. I use my app fluid for this but I also make my own fluid. I use water, alcohol and some dish soap. The mixer helps clean the glass properly before application and works great during application.

Make sure the glass is clean so the vinyl actually can adhere well to the glass!

-

1

1

-

-

5 minutes ago, dcbevins said:Yeah that's fast, but if it works it works. I go 300-400 speed, 200 if it is something I feel I have to heavy babysit. I go 90 grams for pressure most of the time. If you hare having to hit almost 800 grams to get proper cuts, something else is wrong like blade depth. That is alot of pressure.

Thats about where I was with my SC

-

1

1

-

Font Help

in Fonts

Posted

My research pulled up no matches. Was starting to lean towards custom myself. Thanks for the effort and input! Much appreciated!