-

Content Count

3,048 -

Joined

-

Last visited

-

Days Won

208

Posts posted by darcshadow

-

-

If the test cut isn't even working right, it is not a software problem, something is wrong with the cutter itself.

-

The other option would be to analyze the design and figure out a way to break it into smaller pieces. Add in some registration marks to get it all lined back up and you're good to go.

-

2

2

-

-

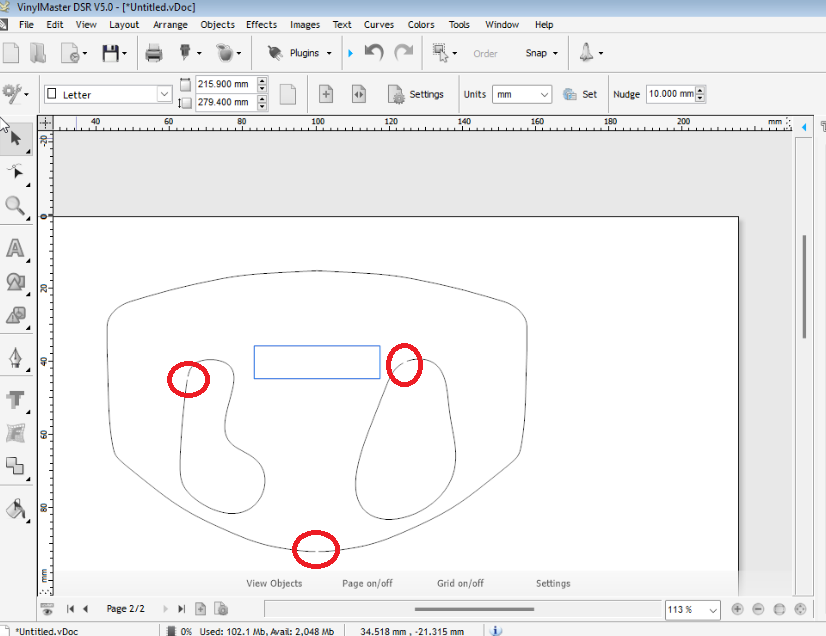

DXF files are not really cutter friendly. They look like a constant line, but they are actually several line segments and are typically not joined. VM can't do a contour, because it doesn't see a shape to contour cut around. You will need to join all the segments in order to create a shape. I might be as simple as joining the 3 areas circled below or you might need to join every single little line segment. Some software has the ability to automatically join line segments that are close enough, although this can give some funky results some times. I believe Inkscape has this ability.

If you can get the file as an eps, ai, or svg rather than a dxf that would be the easiest way to go.

-

2

2

-

-

If the drivers installed it should work with 11. but it wouldn't hurt to try and older version of Windows. Several on here are still running XP for their cutting computer.

The cutter is listed in your pull down menu for cutter selection now, correct? Did you buy the cutter used and did you ever see it work?

-

Is it a tiny little J kind of look? Some of the high end cutters do that on purpose to get the blade going in the proper direction before the actual cut starts. I've not experienced it but have seen it posted here and there is a setting to have the cutter make that pre-cut inside or outside.

-

-

This is one of those cases where working for a large company can be so frustrating. You can almost reach out and touch the part yet you can't get it purchased.

Can you convince your company to buy you a 3D printer? It's a simple design and would be easy to print. I bet with some of the flex able filaments it would work quite well.

Or just put some tape over the hole and make your own hole that is the same size as the original.

-

I moved this to the Flexi section of the forms. If the image prints correctly when you send it to a "normal" printer but doesn't when you send it through FlexiPrint I would look at FlexiPrint as the problem.

Have you tried reinstalling FlexiPrint?

-

If that's the case I'd try changing the hole size. Some duct tape with a hole punched in it would probably do the trick. The hole might get larger over time but it'd be an easy fix. Or a small circular piece of polycarbonate (Lexan) with a hole drilled in it and then taped in place. You can get 1/16" thick sheets from amazon for about $7. Could probably even cut a circle out of a plastic party cup.

Another option, and it's bit more extreme, drill small holes in the suction cup part so that it doesn't make an air tight seal. If the suction is strong enough it should still pick up paper.

-

1

1

-

-

I just did a google search for Graphtec F-Mark 1 suckers. First link takes me to a UK web page, https://graphtecgb.co.uk/product/graphtec-f-mark-vacuum-suction-cups/.

Seems the red/Orange ones you have are for the F-Mark 2. The F-Mark 1 has green suction cups now.

Looks like the big difference is the size of the hole. You might experiment with making the hold smaller on the orange cups you already have.

-

I believe you have to deactivate it on the old computer before you can reactivate it on the new.

-

I don't know about printing, but when you click "Send to Cutter" from there is where you can do the tiling thing. Might try looking for something like that in the print option.

-

And just a matter of terminology, you're not die cutting. Die cutting means you use a die to cut. A cookie cutter, for example, could be considered a die cutter.

-

Same version of VM on both systems? Do you get any sort of error message, what exactly happens when the file doesn't open?

-

Might try running the program using the "As Admin" option. If that works you could then try to figure out exactly where the program is writing and change folder permissions to allow full access to said program. Or just continue using the As Admin option.

-

Ronni only has 3 total post and this one if from 11 years ago. I would not hold my breath waiting for a responce.

-

The Z-chip as everyone calls it, is nothing more than a simple LM741 Op-Amp. Should be able to pick one up for about a $1.

-

1

1

-

-

With the old laptop, where you using the serial port? And the new laptop you're using USB? If installing the cutters drivers don't fix the problem I'd suggest trying a usb to serial adapter, a good one. The recommended one from users here is the Tripp-lite KeySpan adapter. It's a bit pricy but it is known to work. You might be able to get away with a cheaper one, but I'd stick with Tripp-lite. I've used their cheaper adapters for years one various projects at work and home.

-

$25 an hour sounds a little on the low side. I'd say $40 an hour, 15min per door, and $20 per number, and would look into hiring a day laborer, or maybe a high school kid or 2 to do/help with the install.

-

It's odd that even though the letters are not aligned, they appear to be cut correctly. My first thought would have been vinyl slipping, but if that's the case I would expect the cuts to look wonky as well.

-

Is there a way to save settings such as Weed Border Panel Margin so that I don't have to type something in every time I want to use the weed boarder option? Defaulting to 0 is really annoying.

-

Nice find. I tried looking for something like that but couldn't find it.

-

1

1

-

-

I can't say for sure but I would guess, yes. I can say that DSR 4 has that ability. You could always download the demo and find out.

-

Actually I wonder if it's Windows 11 that is the problem. Neither the program or the firmware mentioned being for Win 11.

Cutting Master 5 Contour cutting is not supported for multi-page design

in GraphTec Cutting Plotter Discussion

Posted

If the design is exactly 24" wide, and you are using 24" wide vinyl, your design is probably bigger than the cutter will allow. When you load the vinyl does the cutter detect the edges of the vinyl? If so, it should also report to the software, or maybe on the cutter screen what the width is. My guess the width being detected by the cutter is closer to 23.5.

Are you allowed to install any software on the computer? There are other Window emulators that could be used to run different cutting software. There is also no reason the computer connected to the cutter needs to be on the university network so there's nothing stopping you from buying a cheap laptop and using it to control the cutter. Or just tell the department that the hardware is not compatible with apple and you are required to run windows to operate the cutter.