StayHungryFL

-

Content Count

31 -

Joined

-

Last visited

-

Days Won

2

Posts posted by StayHungryFL

-

-

I figured it out...poor choice of language on the software "position the laser"...once I positioned the BLADE (or pen), it worked fine...it's far from perfect, but it works.

-

I'm still trying to figure out where to lineup...I'm about 2" off...? Looking through the manual, there's no laser point of reference.

-

I am DEFINITELY looking into upgrading my press if this keeps building as it has. I had to start somewhere I guess...lol

-

Just now, julian keller said:I had the same question and it came down to how small is too small. I was trying 1/8 and would get the issue really bad but on 1/4 it was not an issue. I would use only the 60 and my speed was around 30(Titan), force 120- 140, and blade depth set just barely halfway from the carrier and vinyl. I just could not get the small letters done right with any of the many settings I tried but then again I also see that using a stepper vs servo matters as well. I see that one of the Graphtech can do 1/4 without issue but again it all is a matter of dialing in and the blade used. I think I was just going past the limit of what i could do on mine.

The first pic is how well it does on HTV with the servo motor. Just about 4.5mm. The second pic is Oracal 651...same size.

-

I do NOT like the clamshell since I have very large hands & arms. I burnt myself 100 times literally! My wife gave me this glove that I stretched out to fit. lol. Now if I have to adjust the design before I press I save the top of my hand.

-

-

Thanks for your reply. I've definitely got the blade depth set well! I now have 3 holders with 3 different blade angles, although I took the advice of other members here and really only use the 60* one. It seems to work really well. Thanks for the tip on the multiple pass! I forgot about that.

On the subject of force, when it "tears up" the small letters, should I decrease the force until it stops? Right now, it adjusts in increments of 3's...is 3 at a time enough to figure it out? This is actually the reason for this post. I have to cut some VERY small letters, and I spent almost an hour setting my blade depth, and it comes out very good...but still takes up the corners on a few letters.

-

What are your typical settings? I've found if I am cutting REALLY small items (631 or any size foil/glitter HTV)I need to drop the speed under 100. I'm still afraid to use the stock setting...not sure why...?

I've been leaving the force alone at 99. I use China blades that aren't the greatest, but I have 60 of them...so for now I'll use those.

Any insight is appreciated. I value the experience here on this forum and appreciate you all helping out so we learn from others' mistakes...

-

So, I ordered some extra teflon sheets, and heat tape to tape a sheet to the bottom platen. The silicone pad sure makes it difficult to slide garments into place. Anyone have any experience with this? Any reason why this won't work? I can't see spending $40 on a platen cover when I can spend $15 on 3 teflon sheets and tape. lol. I have done several shirts already and it seems to be holding up just fine so far...

I may do it to the top as well as I keep forgetting to put on a teflon cover sheet when I'm in a rush. Sometimes the carrier sticks a bit and pulls up. Need to learn to SLOW DOWN!

-

The text on my logo for t-shirts is 7mm. I took the advice offered here and used one of the cheap 60* blades I bought on Amazon. That, coupled with the fact my 30* blade was starting to get dull after about 100yds of vinyl cut...made for an AMAZING cut! I had the hardest time finding the lines to weed without my loupes. Everything pulled out perfectly and the little 7mm letters were perfect. I can't imagine a clean-cut blade! Thank you all again for your experience and continued great advice. I am now over 100 shirts, and 50+ transfer decals in (including back window marketing), and I feel like I am really starting to find my groove the business, and I am starting to learn the quirks of this Titan3 and SCAL4. I've grown to like it now...(Even though I do the difficult stuff in AI).

-

3

3

-

-

1 hour ago, ShaneGreen said:Recently there was a thread where we discussed the merits of different blades. I cut the same image with a standard 45 and then with a Clean Cut 60...HUGE difference. I'll never go back.

http://forum.uscutter.com/index.php?/topic/54960-small-lettering/&

Thanks I'll have to check it out. All mine just showed up...30 blades from china. I figure they lest me like 3 months tops. LOL!

-

After wasting about 6 ft of HTV this weekend because I was in a rush, and didn't take my time to check, and double check. I decided I need to make a little change to HOPEFULLY jog my memory before I send something to the cutter. I think maybe 3-4 times I forgot to mirror the image...2&3 color designs...cut all the layers and even STARTED weeding before I realized I screwed up...UGH! Learning curve I guess! lol!

-

Good thing I just stocked up on 30 blades...10 of each HAHAHA...whoops! Thanks once again! You guys/gals are a great resource and so helpful! Sorry I'm such a pain!

-

I know this is an old post, but I found using carrier sheet resolved my issue. I was having the same thing happen. It normally doesn't happen with 651 because it's much thicker with the paper backing. I cut around the same speed & pressure you have shown. did 20-30 shirts so far this weekend without incident. I actually went to Michaels and bought a Cricut light grip cutting mat (the light blue one) and it works fine. Just thought I'd answer in case some new people stumble on this.

-

Reading some conflicting advice, so I wanted to ask those of you that have been using the TITAN3 for some time. On the blade pack, it says the following:

30* - HTV

45* - General cutting

60* - Thick materialsI have heard from others they have great results using the 60* blade with very detailed, smaller designs, and the 30* for large cuts. Which is correct? I honestly am getting a lot of great results with the 30* blade for both HTV and 651. The blade does get some small pieces of vinyl jammed in it from time to time, but otherwise, it's been perfect.

Also, Aftermarket blade holders? I am looking to have 3 holders to hold all 3 blades. That way I can set the blade and just change the holder with the new angle blade and not have to play with the depth as much when I need to change them. Thoughts? I bought a pair of cheap ones on amazon, but they don't lock the blade height only the holder height. http://a.co/aMa6PhY They fit ok, but I haven't cut with one yet.

Thanks!

Scott -

1 minute ago, Cal said:Scott, if your machine has a pen tool you can reduce the amount of wasted vinyl by drawing out your design first.

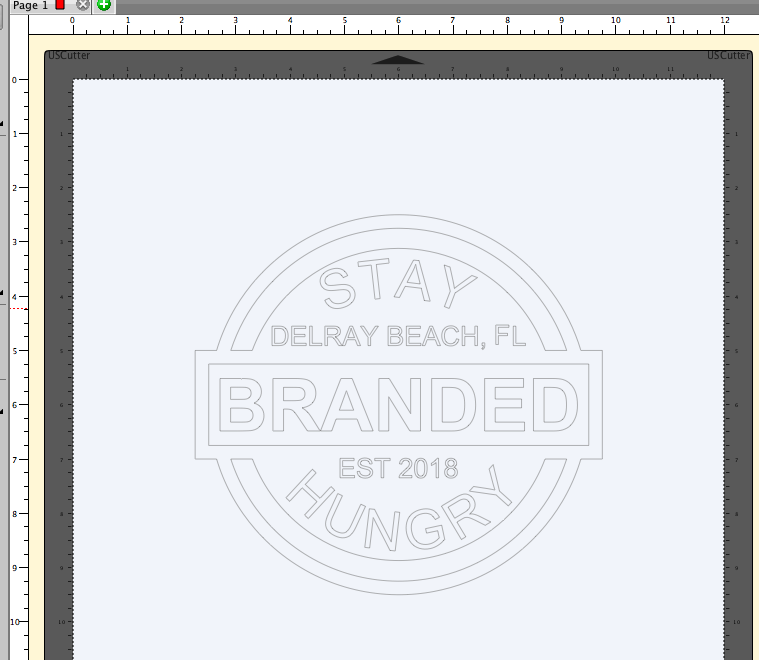

Another great idea Cal...just on paper? Never used the pen...but I noticed in SCAL how I can see the cuts now without colors in the way and I feel like I've come a little further with at least my logo... I got rid of the double cuts that were going through the vinyl. That was most of my issues...even though the blade was set what I feel is properly. I can use the holder on scrap, draw a circle and it only cuts through the vinyl layer. When I cut my logo now, it doesn't go through anything.

-

2

2

-

-

Feeling like an idiot now. I am actually pretty good with AI...I've been using it since version 2...I didn't even THINK to design in there and import. Great helpful tips everyone...thank you!

Scott

-

2

2

-

-

2 hours ago, haumana said:I know some think it's obsolete, but Sign Blazer Elements, which is also free, will get the job done! So far there hasn't been a project that I've done, that I couldn't do it with SBE.

You'll find your footing, then become an old pro!

That's good to know...I'm 1/2 way there...I'm already old! lol!

-

1

1

-

-

1 minute ago, Wildgoose said:There is definitely a learning curve and you may actually have some preconceived thought processes that are steering you wrong going from a craft machine to a real cutter. As to designing, I see in your pic that the script fonts were not "welded" together causing a little gap where the blade cut each letter fully out. You'll get it all figured out. I never was that happy with SCALP as a design program and the cutting mat size issue as a cutting tool is sort of a SCALP thing. I don't think the rest of the cutting world does it that way. I bought a BETA version of SCALP and tried it out but was not impressed and went back to SignCut Pro which is mac compatible.

I'm taking a few hrs each day to learn the machine. I also bought a bunch of spare blades and a few other blade holders to make it easier switching between materials. I also bought a few rolls of Oracal 651 and Siser Easyweed so I don't have to use these sheets any longer. I'm going to check out SignCut Pro...thanks. Appreciate the help. I checked off that "weld" box on/off 4-5 times...it cut the same every time. Merge did some weird stuff with the cuts as well.

-

I solved a lot of the "wrinkling" issue when cutting by taping up the holes that were not being used which in turn caused more suction to the vinyl. No different than using bigger material that covers them all right? I can just remove it when my new stuff arrives. I also slowed the speed down to 96mm/s and left the force @ 96 since I knew my blade was set properly. Cut a few designs now without incident using the 30* blade also...that made a difference too. Just thought I would share that with people that may be having trouble.

-

-

Thanks Skeeter...yeah, "print" is a habit. Thanks for the tips. I read the manuals...but wasn't finding exactly what I need. I think I will also try a carrier sheet for the smaller pieces and 1/2 sheets. Hoping I don't have to re-adjust things too much when I do.

I am just trying to use up all the vinyl I bought for the Cricut...didn't want it to go to waste, but you can bet I'll be buying rolls from now on.

-

Sorry to be a total pain, but there really is NO INFO about this machine...

I have some questions as to where to place the sheets, how far fwd they should be fed...so many problems because I think I was used to that "craft" machine and now reality has set in that I need to actually KNOW how to use this one to get it to print correctly, yet I can't read anything really to figure it out. It's trial and error with a ton of wasted vinyl.

I got it to make some nice cuts with Sure Cuts A Lot, using the WYSIWYG mode and a "fake" mat size of 15"x12". This way I can kind of center the image up and it seems to do ok. When it gets to the bottom of the vinyl, it isn't held by the 2 rollers anymore and the blade grabs it. I also found I had to slow it WAY down and adjust the force. The default setting seems to be too fast and too much pressure for smaller intricate designs. Does anyone use sheets to cut with this machine? I'm scouring YouTube to try and research but I'm not having a lot of luck with the smaller one. Thanks AGAIN!

-

LONG hold time, but they hooked me right up! I had to take it apart. The power supply switch was in between 115/220. once I slid it to the right spot it fired no problems. Now, I have to find the right speed settings because this thing is FASTTTT and tearing up my test vinyl....no worries. I knew it would be some trial & error! Gotta get used to setting the blade after I load vinyl. The old Cricut did it automatically from the same point all the time, so that's all new! Thank @haumana!

-

1

1

-

rollers?

in Table TITAN Series Vinyl Cutter Discussions

Posted

Does anyone put rollers behind their 15" cutter to hold the rolls while you cut? Is it worth it? Just a thought...