Anetski

-

Content Count

27 -

Joined

-

Last visited

-

Days Won

1

Posts posted by Anetski

-

-

9 hours ago, slice&dice said:Subject covered already; a quick Forum search produced this ---

thank you

-

I am looking at the Roland rRueVis VF2-640 which prints with eco solvent inks. Does anyone have these? Are they suitable to have in your home. I have a very large office on the ground floor level of our home. I am just wondering if they still smell being eco?

Thank you

-

Thank you for all replies. I got the two rollers to fit at the right end and it works perfectly now.

thanks so much!

-

2

2

-

-

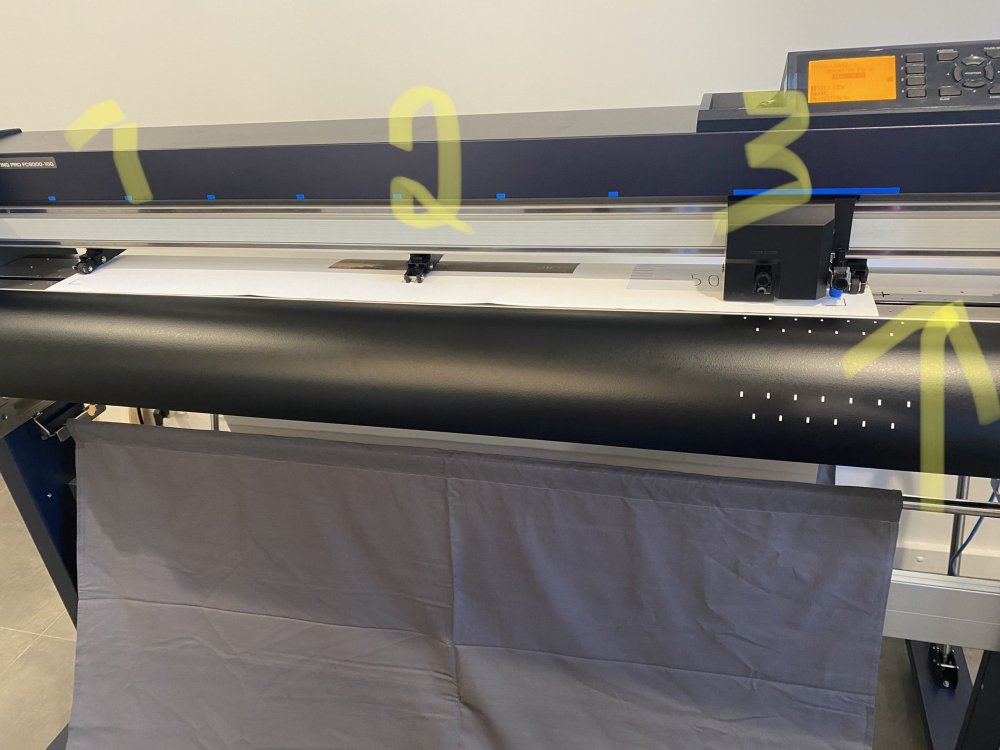

I am not sure there is space to put both pinch rollers on the large grit roller. It means I would have to push the 2nd roller further in on the material leaving less space to print on.

where are the media sensors? Is the material not on them as I have it on the picture? I have always loaded my media this way.

thanks again for your help

-

On 6/24/2021 at 2:15 AM, MZ SKEETER said:why can't you put pinch roller right side 1 and 2 on the large grit roller? The far right not on the material. There is a screw to loosen behind and slide the 2nd pinch roller over with the first. Then you would only be using 2 pinch rollers on the material. Left side and right side of material. I have an older FC-75. (only 2 pinch rollers) I turned off my pinch roller sensor and media sensor on day 1.Located in background settings. But I wouldn't think you would even have to do that. I cut small scraps, so I use 2 pinch rollers on my large grit roller all the time. Worth a try instead of tearing this new cutter apart.

I tried to move no 3 push roller to the right end off the grit area. I turned the push roller sensors off and then tried to cut using only push roller 1 and 2 sitting on each end on the grit area. It wouldn’t work.

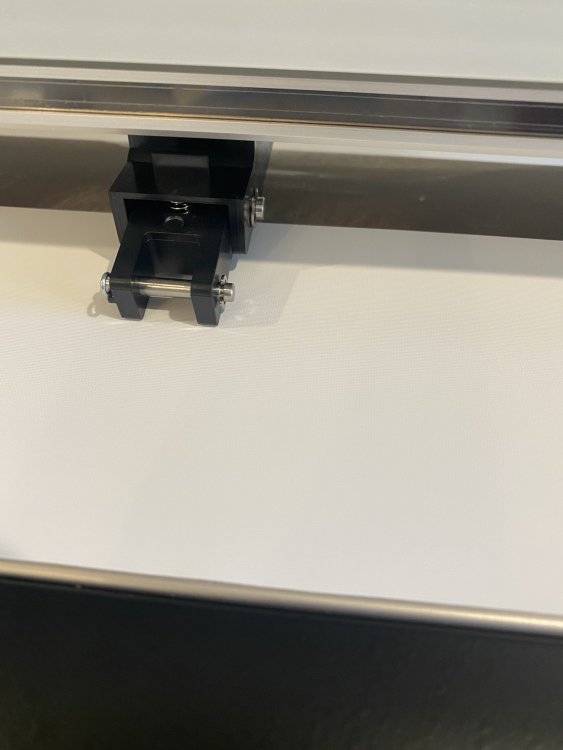

right now I have it set up like pictured with the middle wheel removed but I cut phototex printed with waterbased inks and if I lift the material slightly as I insert it may hit the middle push roller and get scratched.

I would prefer to just push the unused roller to the end on the right.

-

If it is ok to remove it? I know I can still cut with only pinch rollers on the edges but I am wondering if the machine won’t work if removing?

-

Hi

I just received my new fc9000-100 plotter. I had a -160 before. I only cut material as wide as 1m and I don't want to use the middle pinch roller. With the bigger model I could put the extra pinch roller to the end but I can’t do that with the -100 model as there is no extra space. Is it possible to remove a pinch roller?

if I leave the middle one on in the lowest settings I will get marks on my material as it picks up the ink.

-

4 hours ago, Anetski said:thank you that actually fixed it. I have just never seen that little cut before on my ce6000 but at least it is not going into the actual artwork now so I am sure it is there for a reason. one more question if you don't mind before I go jump of a cliff?

I just did two tests on a 1metre wide sheet. I cut one long rectangle twice. First time with force 15 (test cut on this force is perfect). half the rectangle to the right cuts but when it gets to the last 20 cm or so it is no way near cut through the material.

2nd test force 24 (test cut is still fine) and it does exactly the same thing. Both ends of the rectangles are cut fine but the top and bottom is not in the last 20cm of the left side. I am loosing my mind over these machines. the ce 6000 was so much better. Never had all these issues.

5 hours ago, MZ SKEETER said:Yes. I keep mine on the outside. Or it will make a mark in the design.

I fixed the cutting issue. total user error.

-

1 hour ago, MZ SKEETER said:Yes. I keep mine on the outside. Or it will make a mark in the design.

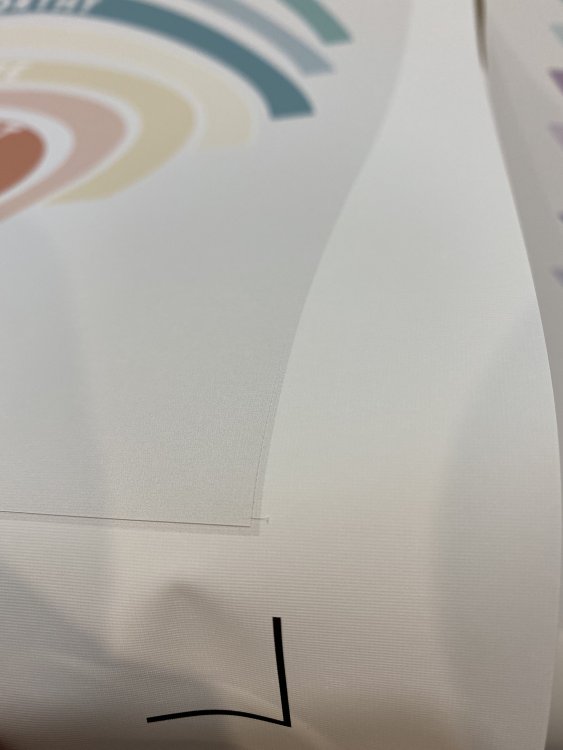

thank you that actually fixed it. I have just never seen that little cut before on my ce6000 but at least it is not going into the actual artwork now so I am sure it is there for a reason. one more question if you don't mind before I go jump of a cliff?

I just did two tests on a 1metre wide sheet. I cut one long rectangle twice. First time with force 15 (test cut on this force is perfect). half the rectangle to the right cuts but when it gets to the last 20 cm or so it is no way near cut through the material.

2nd test force 24 (test cut is still fine) and it does exactly the same thing. Both ends of the rectangles are cut fine but the top and bottom is not in the last 20cm of the left side. I am loosing my mind over these machines. the ce 6000 was so much better. Never had all these issues.

-

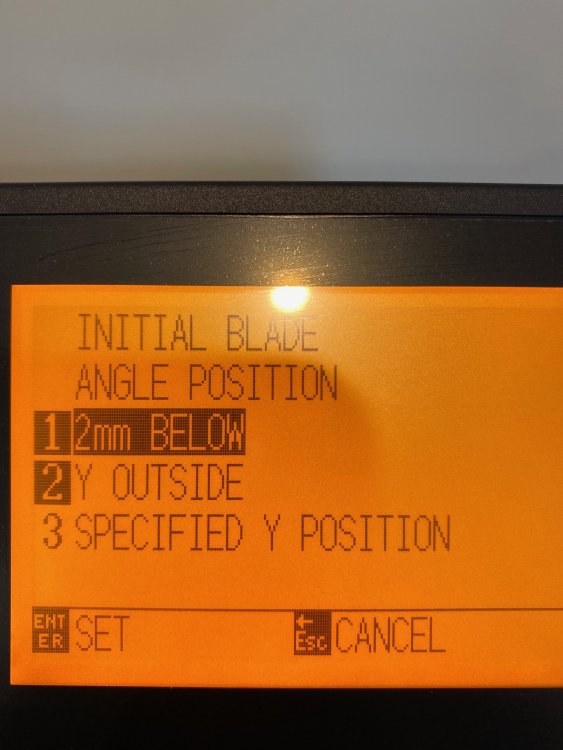

15 minutes ago, MZ SKEETER said:Just checking, in your menu, where do you have. Initial blade control position set at? Mine is in background settings on the FC7000. As far as i have seen, you have never showed us any kind of software settings. so we don't know what your doing.

is this what you mean?

-

Just now, MZ SKEETER said:First off, those marks from the pinch rollers come out when you apply the vinyl. The FC9000 have not been out that long. I don't know of anyone who has one.

I cut phototex. I am not sure what you mean by "applying the vinyl"?

-

1 minute ago, MZ SKEETER said:If the techs can't correct the problem, then I would be getting a NEW cutter. Has this been brought up yet? I would be demanding a new cutter at this point, or your money back.

3 different tech have tested it and after changing firmware and it still faulting, not right away but after 20 or so files it would fault. The problem is only with curves. we have changed it from connecting from usb to ethernet and changed the cutting master software. they also brought in a window computer and I would save the cutting file in cutting master 4 on my mac and then send it to the other windows computer and send the job from there and it still faulted after 5 files.

they have installed a new FC9000 as a loan today to see if this faults as well indicating a problem coming from my computer or if it was indeed the machine.

I just sent two files with rectangles to the new machine and it did this weird little cut on the side which actually went into the artwork. Have you ever seen this before? test cut is fine and the I cut 2 rectangles out of a 1 metre wide sheet and the 2nd rectangle did not cut through at all. I increased the force and it did the same thing after. Could it be that I am only using a pinch roller on each edge and not one in the middle? I did that with the fc8600 and no problems. I found that when using a pinch roller in the middle of the artwork it would leave a mark.

thanks for your input. I am actually loosing my mind over these cutters. I miss my ce6000.

-

I have just sent two files to cut and all they are is rectangles and the cutter (fc9000) seems to do this additional cut on the side before starting the actual rectangle. The little cut actually goes into the artwork and ruins the poster. The only cut line in the file is the rectangle. What is this?

-

On 4/16/2020 at 7:45 AM, Dakotagrafx said:In your graphtec software you can cent parameters like condition, force, etc, Did you check that first before sending the file with circles?

every single setting has been rechecked and tested by 2 technicians that have worked with these machines for years. they have no idea.

-

On 4/9/2020 at 11:33 AM, slice&dice said:Can't see from the pictures or video, but what does the cutting strip look like? Is it gouged or clean smooth?

I helped set-up a brand-new cutter for a friend recently (not Graphtec) and there was a protective tape over the nylon cutting strip, that had to be removed 1st. Until we did that, it cut like crap (not noticing there was the tape on there).

did the video play for you? It is cutting a shape in minute steps even though all the settings are normal. I have had 2 very qualified technicians out 4 times now and they cannot for the life of them figure out why it is doing this only one curves. It changes the cutting to either minute steps which almost sounds like the blade is being dragged or to perf cut. when they reset the firmware (brains of cutter) it goes back to normal for a few cuts and then fails again. They have replaced the firmware too. We connected the cutter via ethernet instead of USB and it has worked fine for at least 40 different file until this afternoon. Also I cannot get a perfect testcut. Every corner is spiky as and only changing the offset on the actual tool setting (not the one in menu) changes the spikes a little but its still not the way it should be plus you can see it on every rectangle that is being cut. 2 technicians that has so much experience on these machines cannot work it out. First the blamed it on my usb port on my IMAC saying it may be faulty and now the ethernet connection is wrong. The files I cut are files i have just set up and using some older artwork in there that I never had any problems with before. Totally lost here and pretty much over it.

-

I got a new FC8600 plotter a month or so a go and within less than 2 weeks when I sent a job through it started almost dragging the blade while cutting circles. I tried a few times and it did it every time. Then I sent a rectangle job through which cut fine and then sent the circle job through again and it was fine. A few weeks passed and it did a similar thing but it started perf cutting on a shape and ever since I have had problems on circles and shapes only. Not on rectangles. The supplier has been extremely helpful and have reset the machine twice but after a few jobs is sent through it reverts back to doing these weird cutting on circles and shapes only. They changed the firmware yesterday and it reverted back again after a few jobs. we have done all tests under the sun and we cannot figure out what is going on. The files are both new and old that I have been using for a few years on a ce6000 plotter with no issues ever. we have updated the cutting master and it has not fixed it either.

The heading I put is a bit miss leading as the machine doesn't actually change the condition setting but just cuts differently. I only do kiss cuts and its always in cond. 1.

Has anyone ever had a similar issue?

-

3 minutes ago, Dakotagrafx said:I love my graphtec for almost anything but if my primary use of the plotter was contour cutting it would be Roland hands down

can I ask which Roland you have? I have the graphtec atm but have just upgraded to a bigger printer so I need to upgrade the cutter as well. I am a little worried to go with a different cutter except my graphtec ce6060 has not always been great.

-

hi.

Which is the best cutter for contour cutting phototex?

-

1 minute ago, Dakotagrafx said:this thread hasn't been active in 5 years - you could be waiting a long time for them to answer - I would try your cb09 blade holder with the 60 degree - been a while since I cut phototex so not sure but thinking you shouldn't need the cb15 for that material

thank you

-

On 4/10/2014 at 9:55 PM, mopar691 said:I cut phototex all the time, never had any problem with it, just slow it down adjust pressure/depth and away you go.

what blade do you use exactly? I have a graphtec 6000 and a CB15UA-5 blade. Its not doing well with intricate cuts.

-

it depends. its normally shapes of different things, dinosaurs, whales etc and so many little bits on them and it just frays in the tiny spots. Drives me nuts. So do you cut original fabric? what blade do you use? I was told by another person to use CB09UA-1 but I cannot find that on the blades list. It has to be a 60 degree blade right?

-

Hi

I have a Graphtec ce6000 cutter and I only cut phototex (original NOT opaque) but I have been using a 45degree angle blade (CB15UA-5) and they just cant do the intriquet cuts. I have now been told I need a 60 degree blade. Could anyone thatcut phototex help me which blade is the best for the original material.

The blade list on the Graphtec website confuses me. Help pls.

Thank you

-

On 3/24/2017 at 3:04 PM, MZ SKEETER said:Found this,

PhotoTexGroup

Hello, So we have 100's of printers that do nothing but process cutout on Photo Tex material all day - every day, but you need the right blade, slow the speed, overlap and has to be a sharp knife as yes this is a fabric. We own 2 Offline cutters a Roland GX-400/600 and so we know to use a 60 Degree Carbide blade. But you can always e-mail me and I can try to help walterjr@phototexgroup.com www.phototexgroup.com Walter Gierlach Jr. , President

Thanks

-

On 3/25/2017 at 2:27 AM, mfatty500 said:Are you changing the setting for use with the u15 blade?

yes

Roland TrueVIS eco solvent printers and "ink smell"

in Printers

Posted

sorry I don't know all the rems but what is OEM and aftermarket?